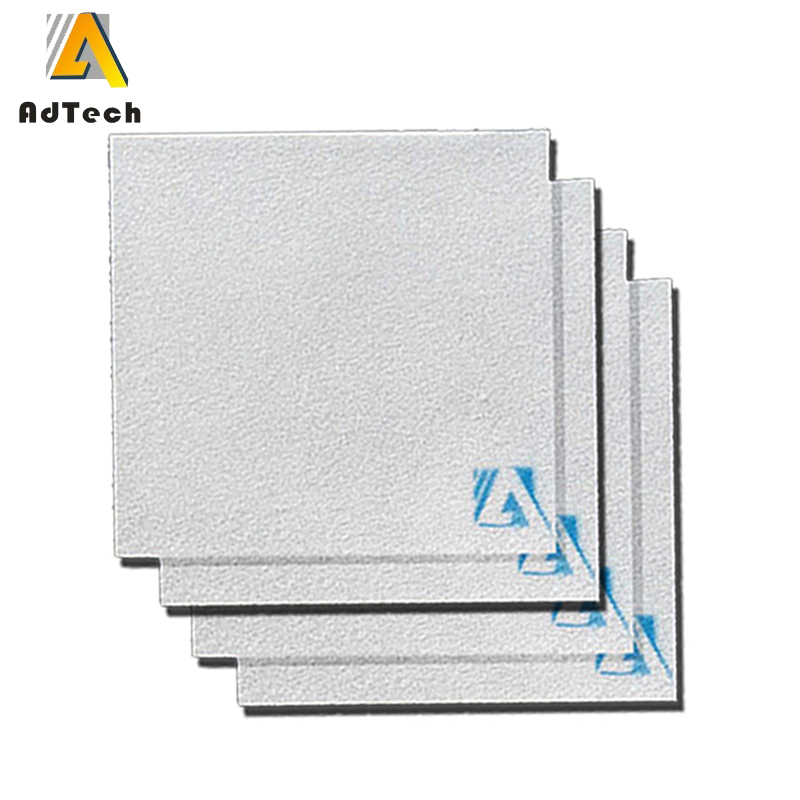

Foam Ceramic Filter Sakthi Portugal is specially used for the filtration and purification of aluminum castings in aluminum rod and ingot factories.

You must choose the right one according to your needs. If your needs are not suitable for common sizes, you can order custom sizes. In order to avoid re-oxidation of molten aluminum during the casting process, you can choose pressureless casting technology. It improves the manufacturer’s productivity and at the same time prepares the filter for the next high-volume shipment.

Ceramic foam cast filters-usually only used for cast iron, steel and stainless steel. The most advanced ZrO2 filter has changed the market structure. For the smelting of cobalt-based and nickel-based alloys, this mechanism is very effective. Mainly in the casting of low-carbon steel and ultra-low-carbon steel.

Ceramic foam cast filter-it is the most commonly used and universal choice for cast aluminum. It is mainly used in cast iron and non-ferrous metal casting devices. You only need to find the precise filter thickness to amplify the bending strength and obtain higher productivity.

The use of vacuum degassing or AOD converter type technology can effectively increase the filter capacity. In order to obtain better performance and better durability, it is important to choose the right filter.

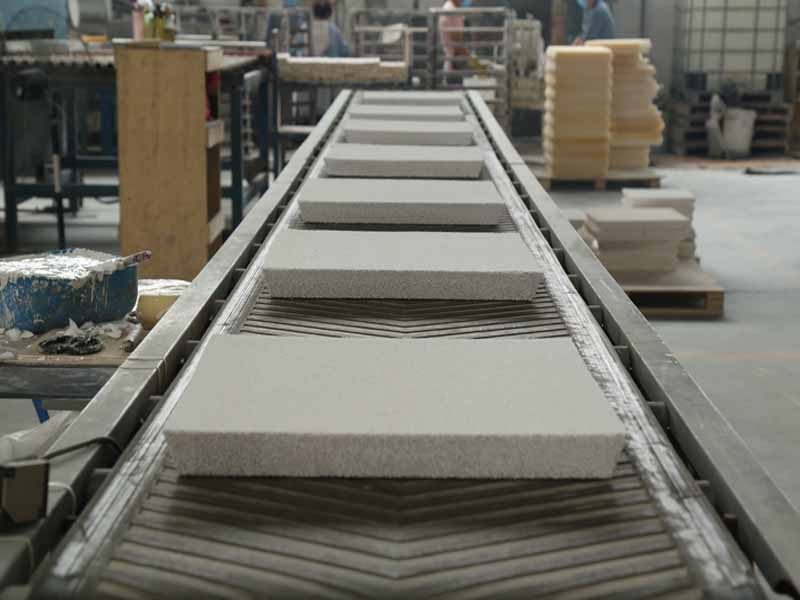

Compared with other purification methods, the filtration method has become the first choice for the terminal purification process of aluminum liquid due to its advantages of low energy consumption, simple operation, high purification efficiency, and less secondary pollution.

(1) Glass cloth and mesh filter mainly rely on mechanical inclusions to intercept and separate, with simple structure and low cost, suitable for filtering out large particles from inclusions, but the effect of microfiltration of inclusions is not great, and the filter heating intensity is low. Short life, unstable filtration, can only be used once, mainly used for pre-filtration of melt.

Foam Ceramic Filter Sakthi Portugal is the most widely used filter in the field of aluminum melt filtration. The advantages are high porosity, high filtration efficiency, convenient replacement, low cost, strong adaptability, and solid inclusions can be separated from liquid inclusions through filtration; the disadvantages are low temperature resistance and short life (mainly for one-time use) ), the amount of filtration is small.