Foam Ceramic Filter Australia occupies a very important position in the melting quality of aluminum melt, which greatly affects the subsequent processing performance and the quality of the final product.

With the continuous improvement of the quality requirements of aluminum products, the application of Foam Ceramic Filter Australia is becoming more and more common. The following is a brief introduction to the filtration characteristics, filtration mechanism, production process and use of Foam Ceramic Filter

The characterization of alumina ceramic filters mainly includes structural characterization, material performance characterization and membrane filtration performance characterization.

Structural characterization is embodied in pore size, pore size distribution, pore type and porosity.

The pore structure of the membrane is closely related to its filtration and transmission performance. Pore size and pore size distribution are the most important parameters of the membrane structure, which directly affect the transmission characteristics of the fluid in the membrane and determine the separation and filtration performance of the membrane surface.

Countries around the world attach great importance to the purification of aluminum melt, and the causes of aluminum pollution are multi-faceted.

On the one hand, during the smelting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-molten state, is easily oxidized, reacts with water vapor and absorbs hydrogen, and easily forms various forms of non-metal slag and crude intermetallic compounds Particles, etc.

On the other hand, some waste materials constituting the charge will introduce some non-aluminum impurities during the recycling process.

Because the waste comes from process waste and waste from various processes in the factory and off-site waste, the route is different, the composition is complex, and the quality is also poor.

These impurities often produce bubbles and inclusions in the slab, which seriously affect the purity of the metal melt, which in turn affects the processing performance, mechanical properties, corrosion resistance and product appearance quality.

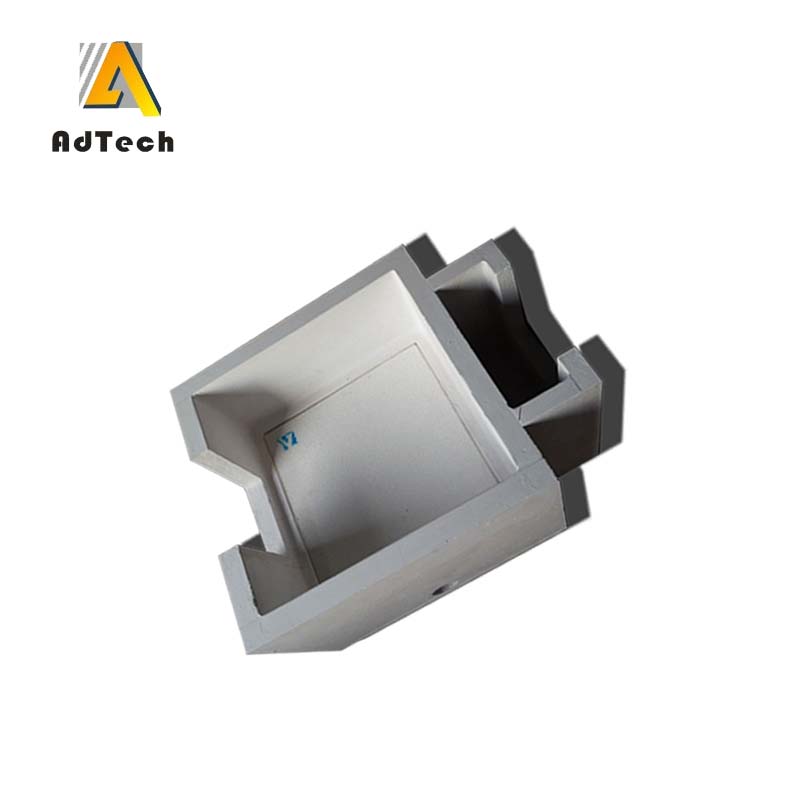

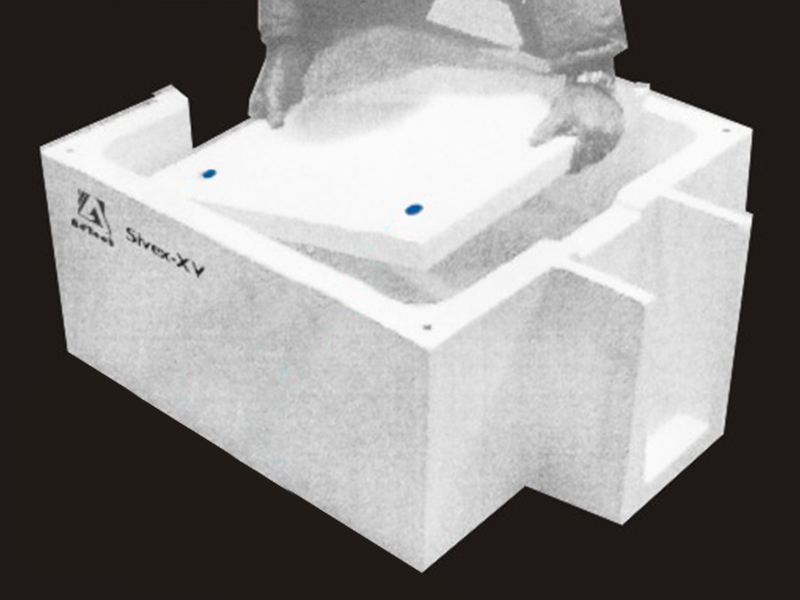

Foam Ceramic Filter Australia is mainly used in the purification process of aluminum and aluminum alloy production. It can effectively remove micron-level inclusions in aluminum water, making aluminum water a stable laminar flow, which is beneficial to filling.

It has a unique corundum structure, good mechanical strength and chemical stability, and excellent resistance to aluminum corrosion.

Strict control of pore size and through-hole rate can obtain stable filtering effect.

There is a sealed ceramic fiber gasket around the ceramic filter plate, which helps to seal the filter plate in the filter box and ensure that no metal liquid is lost.