Foam Ceramic Filter Aluminum Indonesia can improve the damage of aluminum alloy metallurgical defects to aluminum processing deformation production and the mechanical properties of the final product.

Therefore, the purification treatment of aluminum melt is an important process in the casting of aluminum rods and ingots.

Before Foam Ceramic Filter Aluminum Indonesia was used, the gas and slag content was too high, which would cause the ceramic foam filter to become clogged.

Therefore, adding a degassing device before filtering can make the purification process of liquid aluminum more smooth.

The current market demand for high-grade aluminum alloys is increasing, and end customers have higher and higher quality requirements.

In general, the demand for high-grade aluminum alloys is developing in the direction of thin-walled, high-strength, and easy processing.

Such cast aluminum alloys have increasingly higher requirements for the purity of molten aluminum.

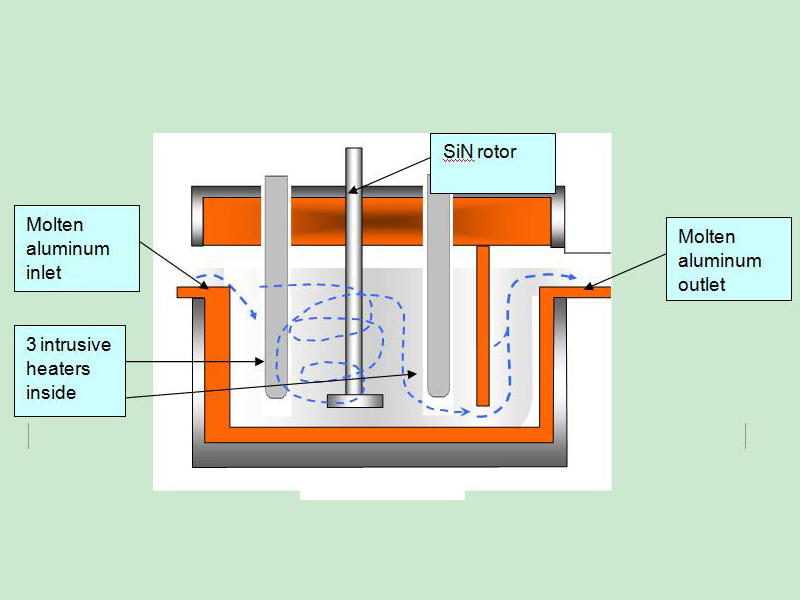

Currently, the most commonly used filtration technology is ceramic foam filtration technology.

The filtering effect of this technology increases as the porosity of the filter plate increases.

Even so, its filtering effect is still far behind the deep bed filter.

Before 2014, Chinese companies were highly dependent on Indonesian bauxite, but after losing this main source of supply, they quickly adjusted their supply channels.

Instead of building a smelter in Indonesia as Jakarta hoped, they found a stable supplier in Malaysia, and switched to Guinea in Africa after Malaysia also banned bauxite mining.

The export ban in 2014 only brought a new smelter to Indonesia. Therefore, the government relaxed the ban in 2017 and promised to reassess it by 2022.

Although China was not interested in investing in aluminum smelters in Indonesia in 2014, the bauxite refining industry in West Kalimantan also attracted some Chinese investment under the encouragement of the “Belt and Road” initiative.

With investment from the Indonesian state-owned mining company Antam, some Indonesian private companies, and several Chinese companies, there are currently six smelters under construction or expansion, three of which are located in Kapua near the villages of Merangao and Merliao Hulu. Along the river. However, the construction speed of these smelters has been slower than expected.

Well Harvest Mining, a subsidiary of Indonesia-based Harita Group, already has a smelter and is currently cooperating with the world’s leading aluminum producer China Hongqiao Group to double its smelting capacity. Borneo alumina company Borneo Alumina Indonesia plans to build a new smelter with the support of Antam and China Aluminum International Engineering Co., Ltd.