Filtration of Molten Aluminum can prevent clogging caused by the solidification of the molten metal due to the oxide film entering the surface of the molten metal or the temperature drop of the filter medium itself.

A molten metal filter medium made of a porous ceramic material and formed into a flat plate shape has been proposed. This filter medium has a large Filtration of Molten Aluminum capacity and can effectively process a large amount of molten metal continuously produced in the smelting furnace. However, a big problem has occurred in the conventional molten metal filter device equipped with a filter medium of a flat porous ceramic material.

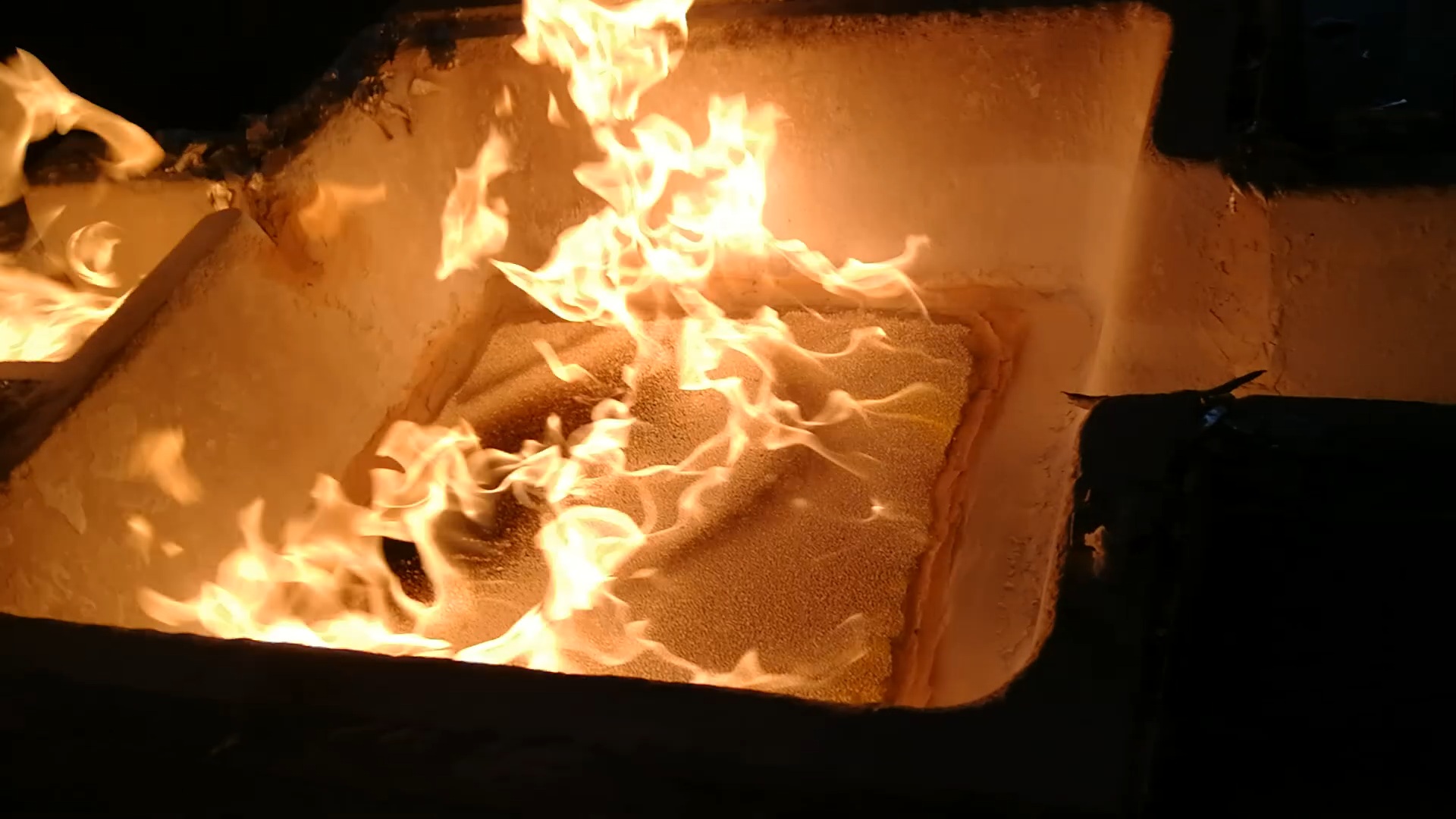

In a traditional filter device, the molten metal flows down to the filter medium. During switching from one smelting furnace to another smelting furnace or after the end of the filtering operation, when the flow of molten metal from the furnace into the filtering device is stopped, the molten metal remaining in the filtering device flows away from the device through the filtering medium.

For this reason, the filter medium is exposed to ambient air.

At this time, because the oxide film (such as aluminum oxide film) formed on the surface of the molten metal in contact with the ambient air in the filter will flow into the filter medium together with the remaining molten metal and adhere to the medium, the medium May be clogged, such as aluminum oxide film.

The filter medium can also be clogged because the molten metal sticks to the medium due to the drop in temperature or remains in the medium metal to solidify the exposed medium in the filtered air.

Filtration of Molten Aluminum enables the filter medium to be attached thereto and detached therefrom without difficulty and provides ample protection for the filter medium.

A horizontal partition is provided in the filter housing formed in the flow path for molten metal.

The horizontal partition has at least one filter setting hole through it, and the filter frame is located therein.

The filter with the filter medium placed in an appropriate position is installed in the filter mounting hole in such a way that the upper part of the filter frame protrudes from the upper surface of the horizontal partition.

The upper part of the filter therefore, the frame protruding from the horizontal partition provides a convenient means for workers to replace and replace the filter frame to replace the filter medium.

[…] foam filter gasket Filtration of Molten Aluminum is surrounded by a sealing gasket, which is placed between the filter and the filter bowl to […]