Filters Aluminium Foundry production process

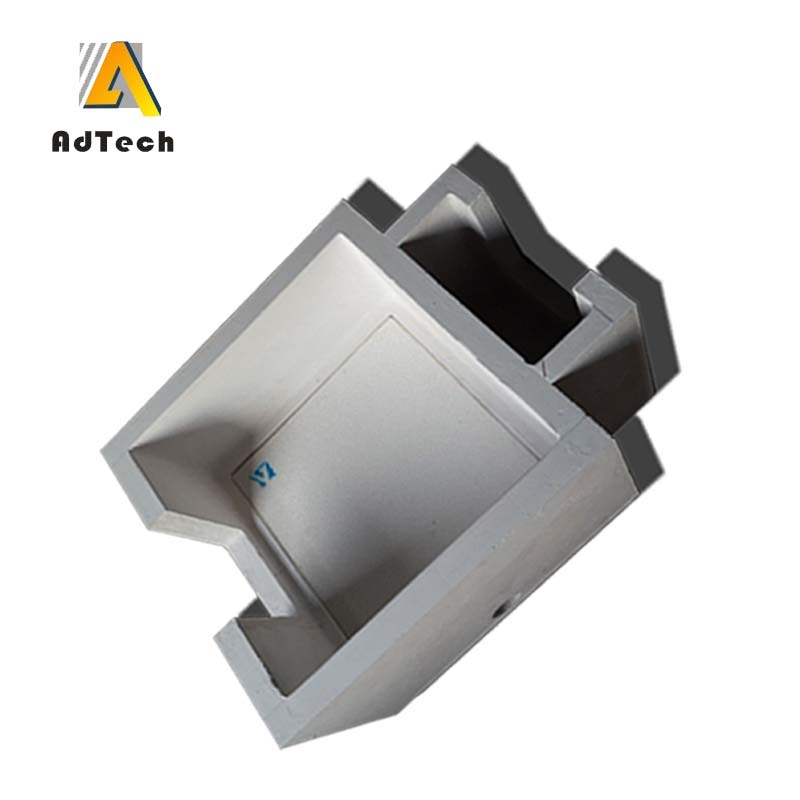

Filters Aluminium Foundry use polyurethane foam as a carrier, immersed in a slurry made of ceramic powder, binder, sintering aid, suspending agent, etc., and extrudes the excess slurry to make the ceramic slurry evenly coated on the carrier frame to form The green body is then dried and sintered at a high temperature.

This process is also called organic foam impregnation method, which is a relatively mature production process in my country.

Alumina ceramic foam filters are classified according to different pore diameters, such as 10PPi, 15PPi, 20PPi, 30PPi, etc. The mesh division of the sponge is different from the classification of the product mesh.

Generally speaking, the larger the PPi value, the smaller the corresponding pore size and the smaller the inclusions after filtration.

If you want to buy Filter Foundry, please contact sales@adtechamm.com

Filter Foundry shaping process

The choice of formula must ensure the best consistency and fluidity of the slurry to ensure that the product can be sized evenly during the sizing process to reach the specified sizing weight.

Because this is a prerequisite to ensure the product strength and through-hole rate are qualified. Its consistency is adjusted by the specific gravity and performance of the mud.

Sponge modification process

Sponge modification is to prepare for the sizing process to improve the sizing performance of the sponge and make the sizing uniform.

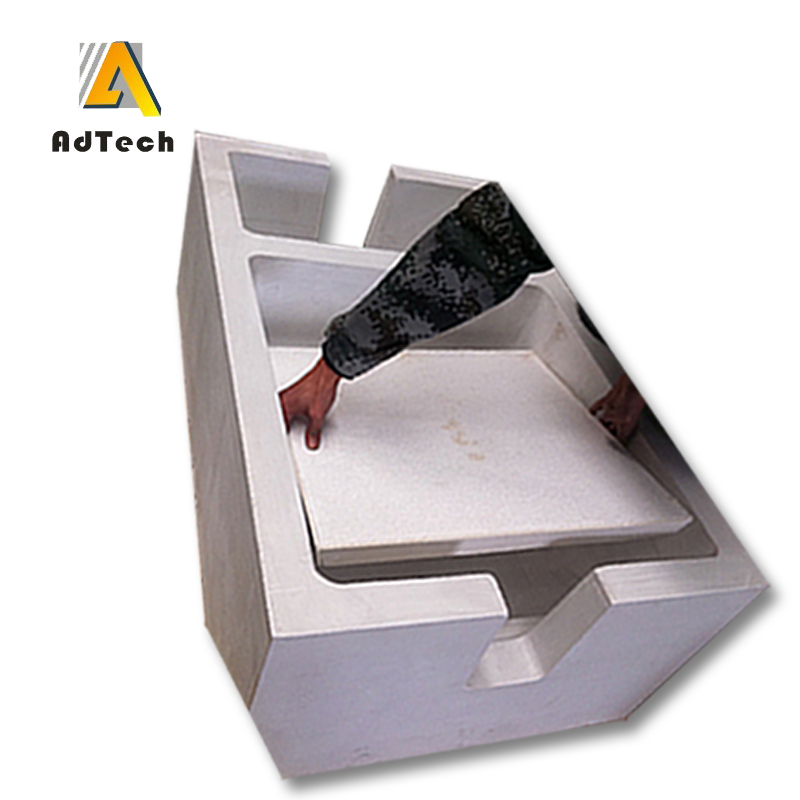

Dipping sizing process

The modified dry sponge product is uniformly coated into a green body through the adjusted slurry on a roller press.

For sponge products of different meshes, different concentrations of slurry need to be used for sizing, otherwise the sizing effect will not be achieved.

Drying process

The drying process is mainly to let the sizing semi-finished product volatilize water, which is generally controlled below 1.0%.

For products with larger specifications, it is necessary to control the drying environment, such as temperature, humidity, etc., to prevent drying deformation and crack defects.

Ignition process

The firing process is the last process in production. Due to formulation improvements and production cost considerations, most of the SiC foam ceramic foam enterprises do not require atmospheric protection, and the firing temperature is generally 1350 to 1450°C.

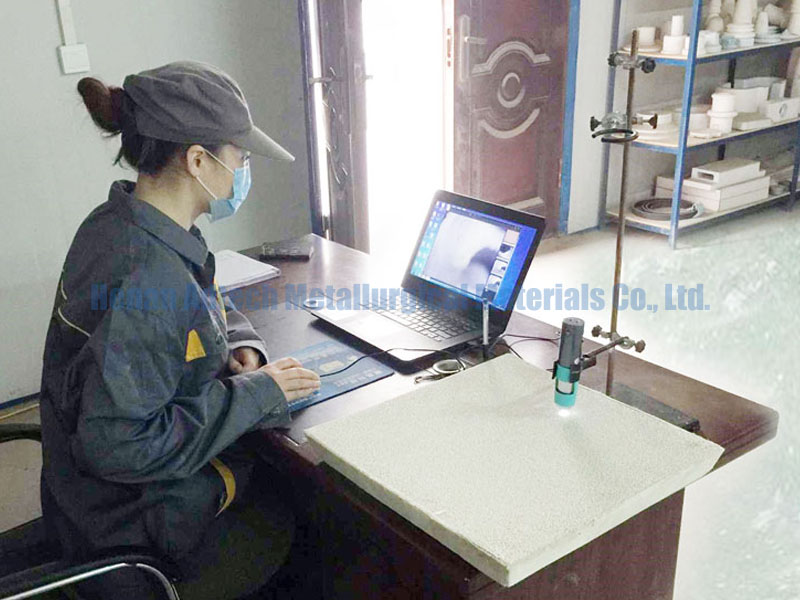

Filters Aluminium Foundry quality inspection process

Due to the porous structure of ceramic foam, the combustion products are more or less slagging.

For foundries, in addition to considering the strength of the filter and the screen, the slag drop phenomenon is also a hot issue that they are most concerned about.

Because the filter itself is used to filter inclusions, its own slag droplets will have the opposite effect, resulting in casting waste.

Therefore, in the quality inspection process, in addition to checking the appearance and internal quality, it is also necessary to clean the slag.