Filter Casting effectively removes large inclusions in molten aluminum, absorbs micro-inclusions in particles, improves product performance and microstructure, and is widely used in aluminum alloy casting and other production areas.

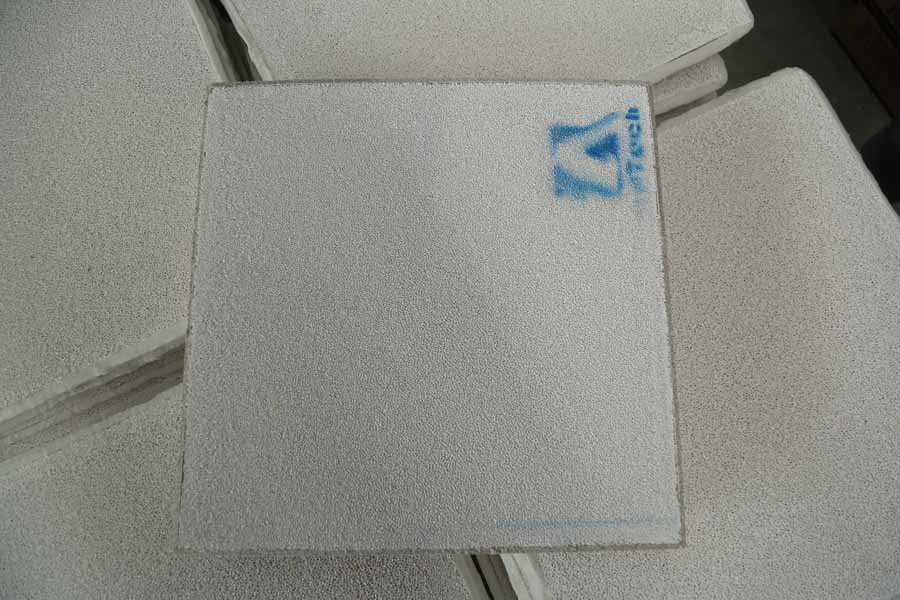

Square porous alumina ceramic foam filter with high purity alumina or fused silica.

It is insoluble in molten aluminum at 800°C or lower, and is resistant to corrosion and chemical attack.

The strength of the ceramic foam filter is sufficient to withstand various processes, so it will not be damaged during normal operation and use during transportation. It has no loose ceramic particles or powder (snowing). A self-expanding gasket or silicate fiber gasket is installed on the periphery.

Features of alumina ceramic foam filter

●Excellent dimensional tolerance

●Stable chemical composition

●Highest filtration efficiency

●Excellent strength

●Resistant to corrosion of molten aluminum and alloys

●Bevel and compressible gasket

Filter Casting uses an effective molten aluminum ceramic foam filter. Its three-dimensional connected mesh structure, high porosity, has the advantages of large slag collecting surface area. The filter has a large internal surface area, a small flow resistance, and a good filtering effect.

Sell high-quality ceramic foam filter.

AdTech provides various advanced ceramic foam filters through sales@adtechamm.com. These structures are widely praised for their robust structure and dimensional accuracy. Because we promise to deliver in time anywhere in the world.

Application of high-quality ceramic foam filter

High-quality ceramic foam filter can effectively remove and absorb various impurities in molten aluminum, improve surface quality, product performance and microstructure effectiveness. Mainly used for precision casting of aluminum alloys such as household, construction, electricity, condenser tubes, cables, etc.