Fcri Ceramic Foam Filter is a good product, which is widely used in aluminum water filtration during aluminum smelting and casting to prevent particulate impurities in molten aluminum from entering the casting billet and affecting the quality of aluminum processed products.

According to the quality requirements of the casting, the flow of molten aluminum, the total amount of molten aluminum after filtration and the cleanliness of the molten aluminum itself, the correct selection of the type of filter box and the specifications of the foam filter plate can obtain a satisfactory filtering effect.

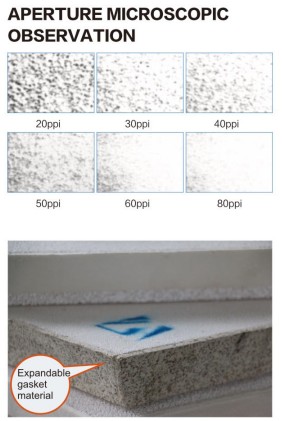

There is an 8mm aluminum silicate lining around the ceramic filter plate to seal the contact part of the filter plate and the filter box to ensure that there is no aluminum liquid bypass.

Ordinary aluminum castings usually use 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

Therefore, 30ppi 40ppi cast filter is the most commonly used ceramic foam filter in the aluminum casting industry. Please contact sales@adtechamm.com to purchase.

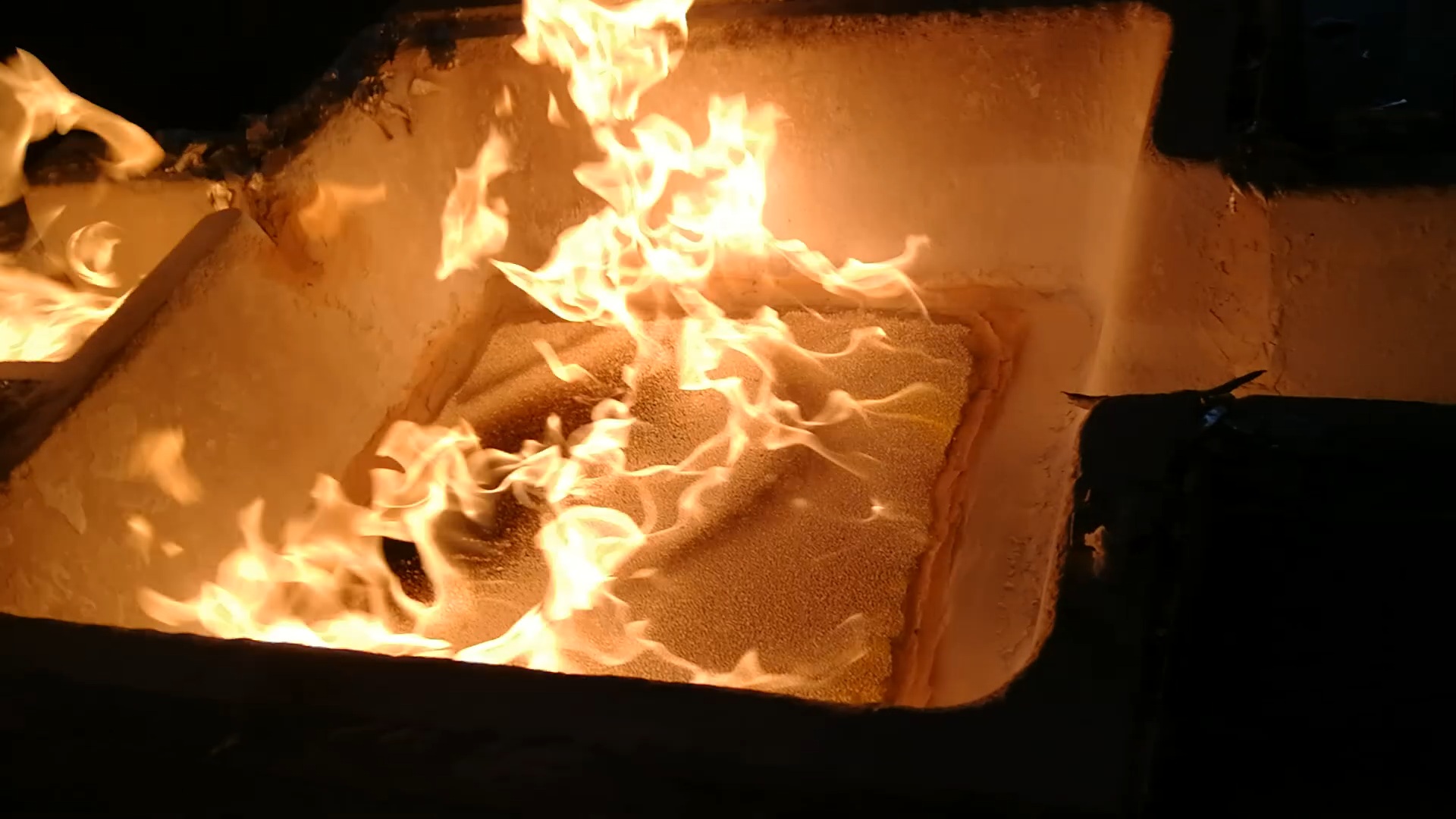

Foam ceramic filters are mainly used in the casting process to purify the liquid casting alloy and reduce or eliminate various non-metallic inclusions and exhaust problems during the casting process.

Casting waste caused by casting defects (such as non-metallic inclusions) accounts for 50%-60% of the total number of waste products.

With the increase of various costs, the damage to the external environment caused by the outflow of excess waste can be predicted. Inclusion defects not only seriously affect the mechanical properties and properties of the casting, but also have a harmful effect on the casting of the casting. Cutting process and appearance of castings.

Fcri Ceramic Foam Filter products effectively eliminate solid inclusions in molten metal, so aluminum alloy can be successfully forged, aluminum foil manufacturing, extrusion processing and other processes to obtain high-quality aluminum products. The product has a selection range of 10ppi coarse pores to 70ppi very fine pores, so there will always be a product standard that suits your requirements. Both ordinary and special sizes required by customers can meet the requirements.

The 30ppi casting filter has the ability of natural chemical adsorption (affinity), which can adsorb impurities such as molten aluminum oxide.

Adsorb the impurities in the molten metal (including particles smaller than the pore size) on the inner wall of the hole to improve the filtering effect.

The advanced extrusion production process makes the ceramic filter have a unique square and triangular design, thereby increasing the contact area with the ceramic.

Improve the filter’s ability to absorb and trap small impurities, which is better than non-squeeze filters, and the molten metal flows smoothly.

Improve pouring speed and continuity.

Reduce casting waste rate.

Improve the mechanical properties of castings and extend the service life.

[…] determined according to the pressure difference before and after the filter plate. The size of the Fcri Ceramic Foam Filter used is determined according to the flow rate of the molten aluminum per unit time and the total […]