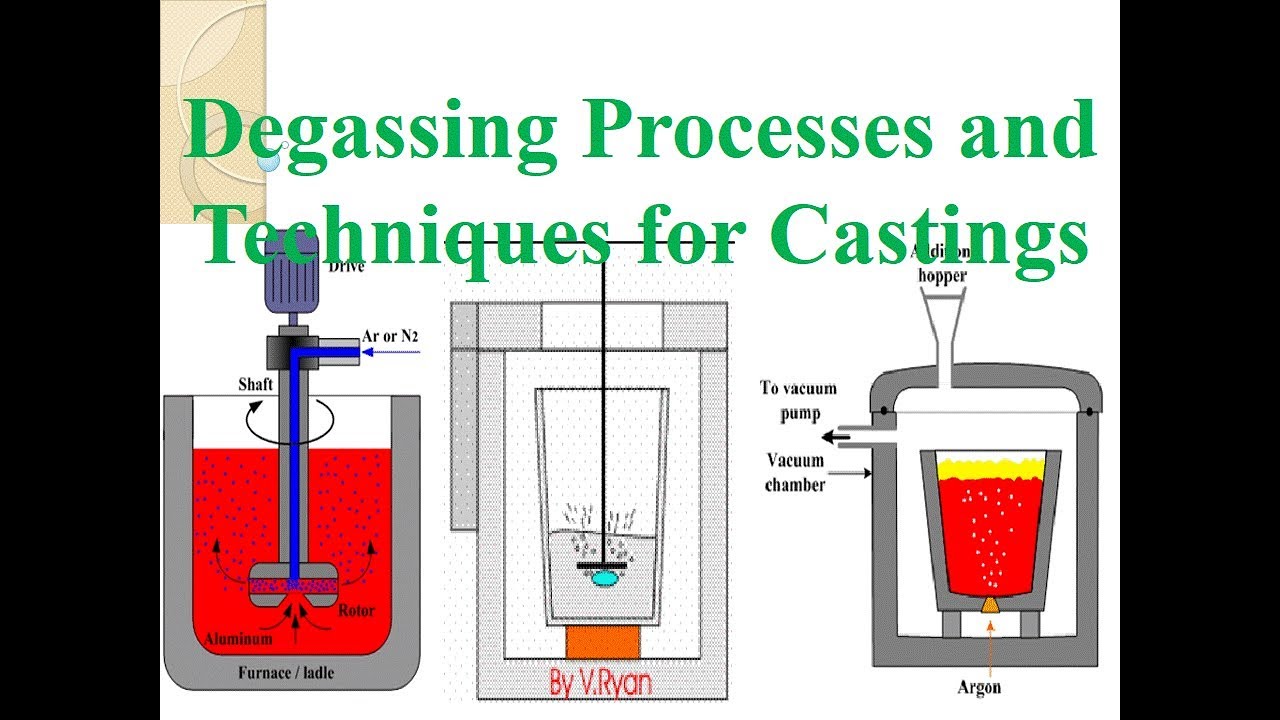

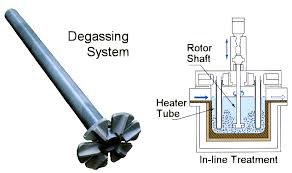

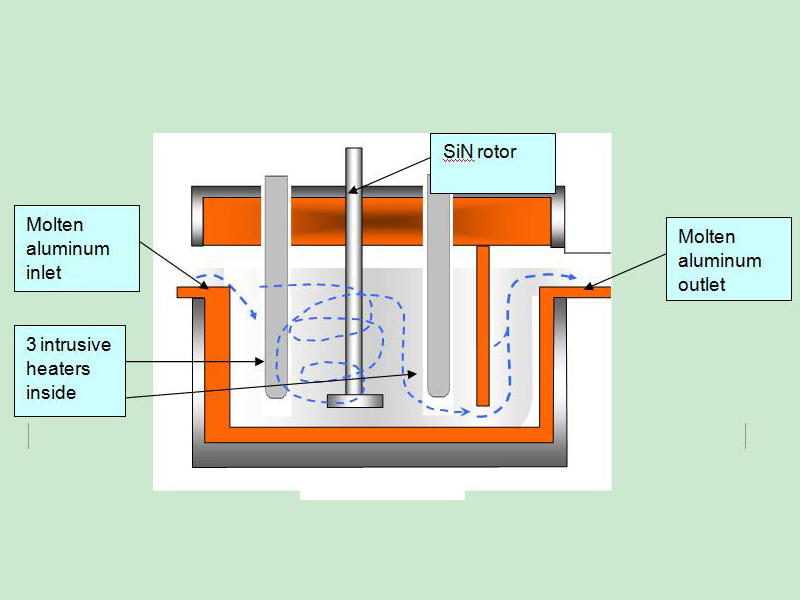

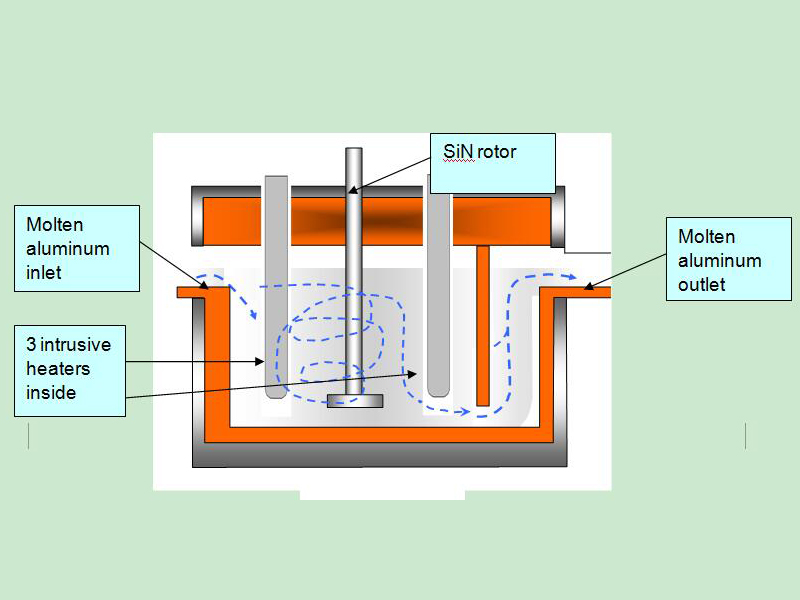

Degassing Purification System uses a rotating rotor to break the inert gas (argon or nitrogen) blown into the molten aluminum into a large number of dispersed bubbles and disperse them in the molten aluminum.

Bubbles in the aluminum liquid rely on the gas partial pressure difference and the principle of surface adsorption to absorb hydrogen in the aluminum liquid, adsorb oxidized slag, and are taken out of the surface of the aluminum liquid as the bubbles rise, so that the aluminum liquid can be purified.

Because the bubbles are small and dispersed, they are evenly mixed with the rotating molten liquid, and then rotate and slowly rise in a spiral shape. When they are in contact with the aluminum liquid, the airflow generated by a continuous linear rise will not form, thereby significantly improving the purification effect.

Both argon and nitrogen can be used as the gas for degassing and slagging of molten aluminum. The purity of the inert gas must be above 99.95%.

Features of Degassing Purification System Degassing Unit

1. Adopt brand frequency conversion controller to adjust the rotor motor, wide speed adjustment range, stable start and stop, long life.

2. Before or during processing, there is an alarm signal such as insufficient gas.

3. The electronic control system adopts Chinese famous brand products to ensure flexible and reliable movement, neat and beautiful, and durable.

5. The remote design of the electronic control system and the deaerator rotor part can ensure that the rotor and the electronic control system maintain a safe distance and effectively protect safety.

6. The lifting adopts double guide rails, which is more stable and safer, more stable during high-speed degassing, and less jitter, which effectively prevents the rotor from breaking.

7. With multiple fault alarms, alarms are given in the form of indicator lights and sounds.

8. It is easy to use and can realize multiple functions in one machine. The operating environment is diverse.