Degassing Equipment is also called: aluminum water slag remover, refining degassing machine, hydrogen removing machine, aluminum liquid purifier, aluminum water removing hydrogen machine, aluminum alloy refining degassing machine, hydrogen removing machine, aluminum ingot degassing machine, aluminum liquid Deaerator, slag remover, fixed aluminum water deaerator, mobile aluminum water deaerator, hoisted aluminum water deaerator, powder spray type aluminum water deaerator, mobile powder type degassing and slag removal Machine, aluminum liquid purification machine, molten aluminum degassing machine, crucible furnace degassing machine, pool furnace degassing machine, melting furnace degassing machine, launching furnace degassing machine, and subcontracting aluminum liquid aluminum water degassing machine, Degassing mixer, melting aluminum purification equipment, copper liquid slag remover, etc.

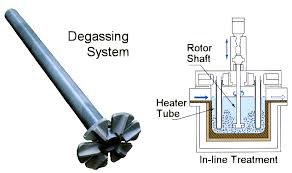

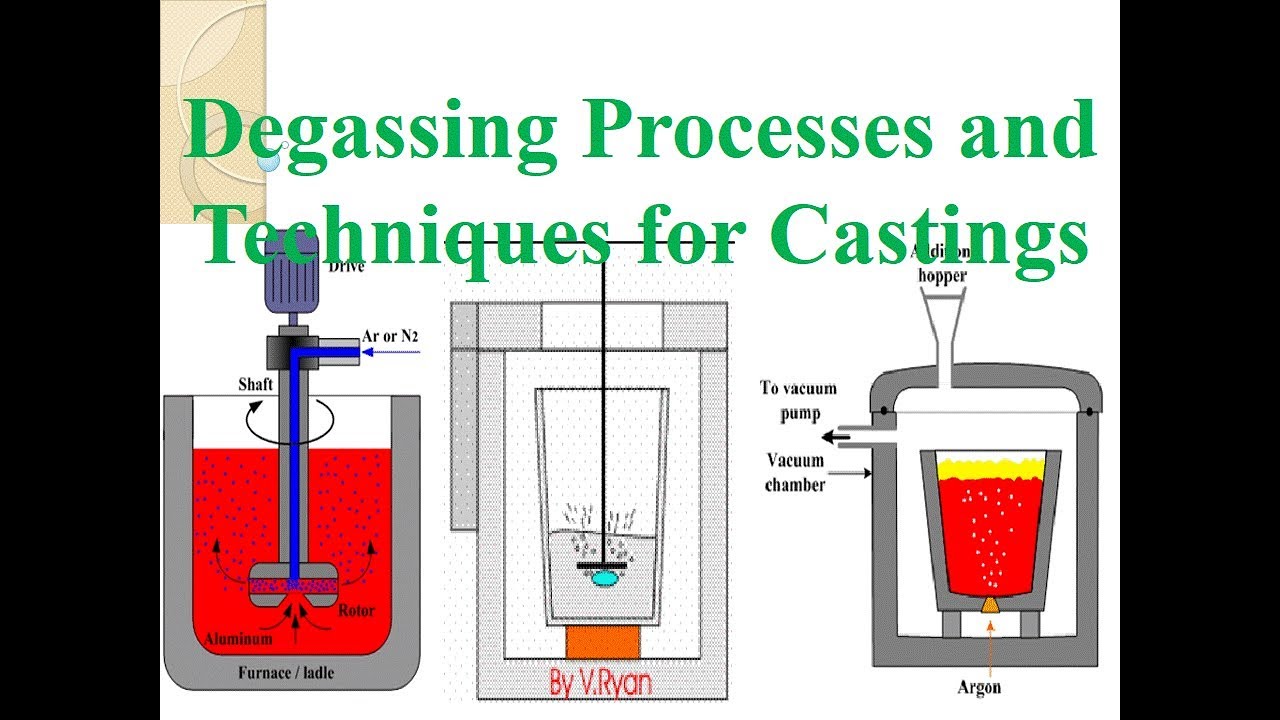

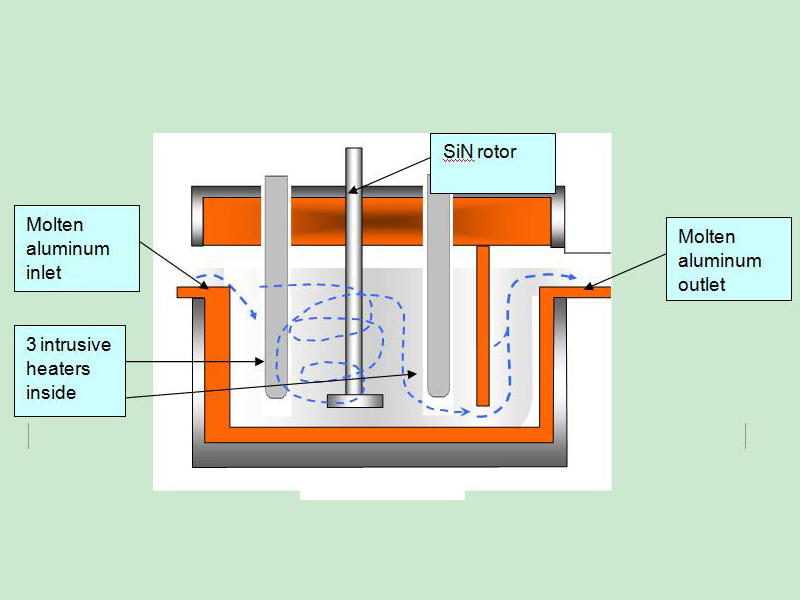

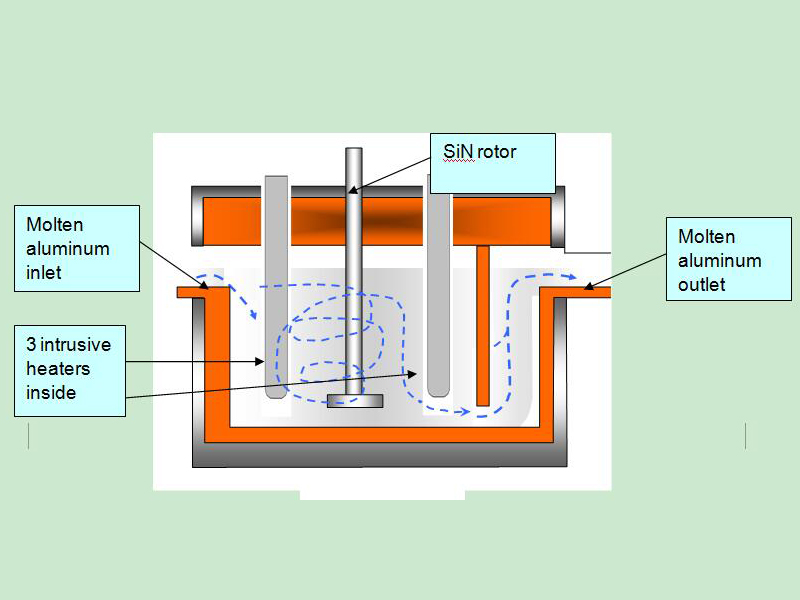

The key to the degassing of Degassing Equipment is that the rotor can disperse the large bubbles of inert gas that enters into small bubbles and diffuse them in the entire molten metal.

By reducing the bubble diameter, the surface area of the inert gas is increased sharply, so that more inert gas surfaces are in contact with the hydrogen and impurities in the molten metal, and the hydrogen or impurities are removed from the molten aluminum as the bubbles rise.

The flow control of the inert gas entering the molten aluminum can be adjusted according to the volume of the metal liquid to be processed. The speed of the rotating rod and the rotor can be adjusted to generate bubbles of appropriate size to facilitate the diffusion of the inert gas.

Both argon and nitrogen can be used as inert gases to degas molten aluminum. The purity of the inert gas must be above 99.99%.

Degassing is to spray inert gas into molten aluminum to achieve the purpose of removing hydrogen.

In addition, degassing is also considered to be a very effective way to float impurities.

Two main theoretical models have been proposed to explain the principle of degassing.

The macro model assumes that the removal of each impurity is similar in nature.

The microscopic model, that is, according to this theory, due to the higher vapor pressure of hydrogen, the dissolved hydrogen diffuses into the injected aluminum liquid. Theoretically speaking, after an inclusion with a diameter of 10 microns is in contact with a bubble, it is adsorbed on the bubble and floats to the surface of the liquid.