Degassing Aluminum Alloys mainly treat molten aluminum containing a certain amount of hydrogen and other residues (alkali metals, slag inclusions), which are removed after being processed by degassing equipment.

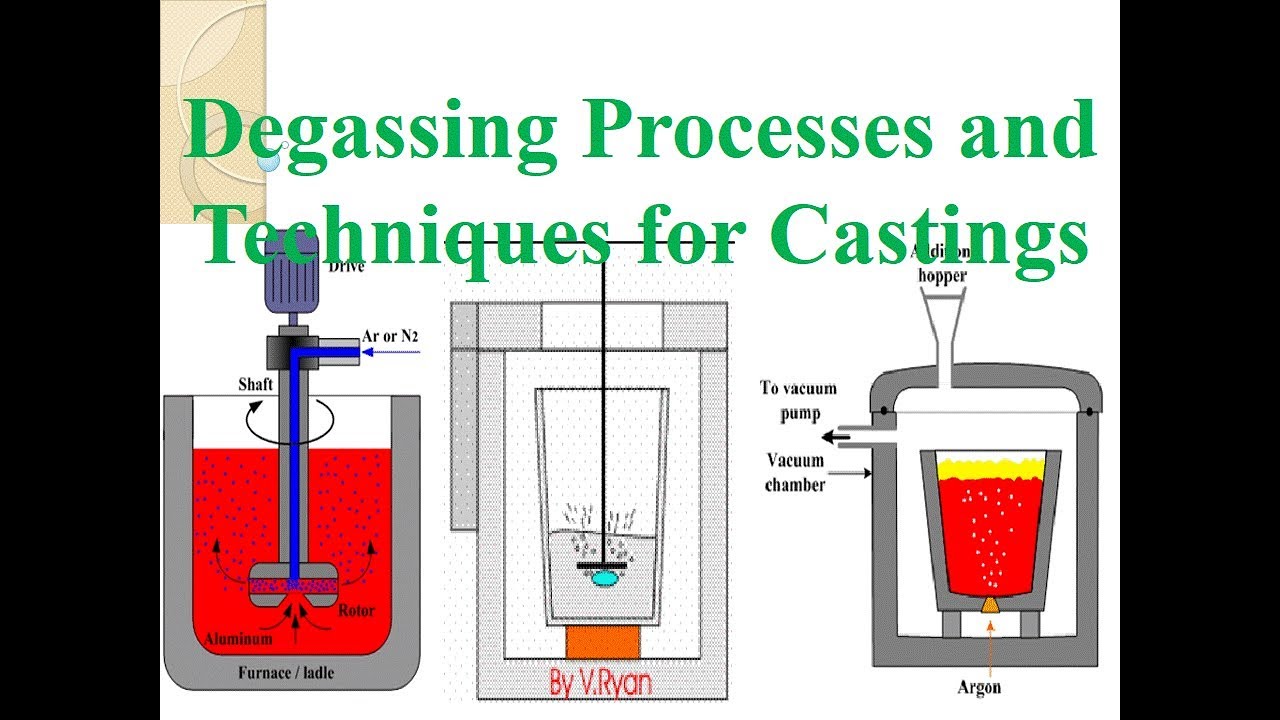

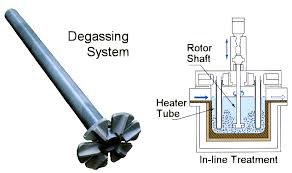

The processing principle of Degassing Aluminum Alloys is the principle of gas flotation. The process gas (inert gas or a mixture of inert gas and chlorine) is injected into the melt through the rotor and broken by the rotor into uniformly dispersed tiny bubbles.

The tiny bubbles rise to the surface of the melt, and the following tasks are completed during the rise of the tiny bubbles:

Hydrogen is absorbed into the bubble and is eliminated.

Alkali metals are eliminated by chemical interaction with chlorine gas (formation of chloride);

The inclusions are trapped by bubbles and then rise to the surface of the melt to form dross.

Degassing efficiency standard design box structure quality standard design rotor standard design immersion heater protection sleeve gas standard design standard sealing structure design.

The double-rotor degasser is specially designed to provide online degassing for molten aluminum with large flow, high gas content, and many inclusions.

Equipped with two degassing rotors that can individually control the gas flow and speed. The equipment needs a special degassing tank. The dual-rotor design can provide more powerful stirring and degassing capabilities.

The equipment is directly connected to the launder system and is equipped with a special slag port. The equipment can lift the heat preservation cover and the degassing rotor by electric lifting, which facilitates the replacement of rotor parts. The equipment has a good heat insulation design and can provide 24-hour online uninterrupted Degassing.

The molten aluminum flows into the degassing case body and stays in the refractory lining. The case body has a heater to keep the molten aluminum in a molten state.

After the inert gas is ejected by the rotating rotor, it is broken into countless small bubbles by the high-speed rotating rotor, and the small bubbles diffuse and rise in the aluminum liquid, thereby removing hydrogen.

During the ascending process of small bubbles, due to the effect of surface tension, a part of the inclusions are brought out from the molten aluminum to the liquid surface, forming scum to remove the inclusions in the molten aluminum; at the same time, the stirring effect of the rotor makes the molten aluminum The alloy composition is more uniform.

The porosity you have encountered is dissolved hydrogen.

Molten Aluminum can even draw it out of the air.

That’s why good foundries cover the heat (melt) to minimize hydrogen absorption.

Also for critical castings, do not pour on rainy or high-humidity days as the casting will have more porosity.

Using degassing tablets should be done immediately before pouring to prevent re-absorption of hydrogen after degassing.

I have only used Foundry-supplied cakes (white) for degassing, but have heard that swimming pool chlorine tablets work well and also have heard that 20 mule Team Borax works. Also, some old timers have used pieces of potatoes, but I have not. I understand the potatoes do not degas the melt, but instead “micronize” the hydrogen into very small bubbles that minimize shrink issues.