China Ceramic Foam Filter CFF

China Ceramic Foam Filter CFF in casting process is a familiar refining technology for casting process.

This technique be able to exist removed the inclusions inside the melts and subsequently improves the mechanical properties of the product.

Furthermore this will also improved the surface finish and tightness of cast product.

This significantly reduced the rework cost. The present research was done to fabricate an improved ceramic foam filter for use in filtering aluminum base alloys.

It was an objective of the present work to provide a China Ceramic Foam Filter CFF characterized by cost of raw materials.

Then experimental tests were carried out to the filters to measure permeability properties before pouring process.

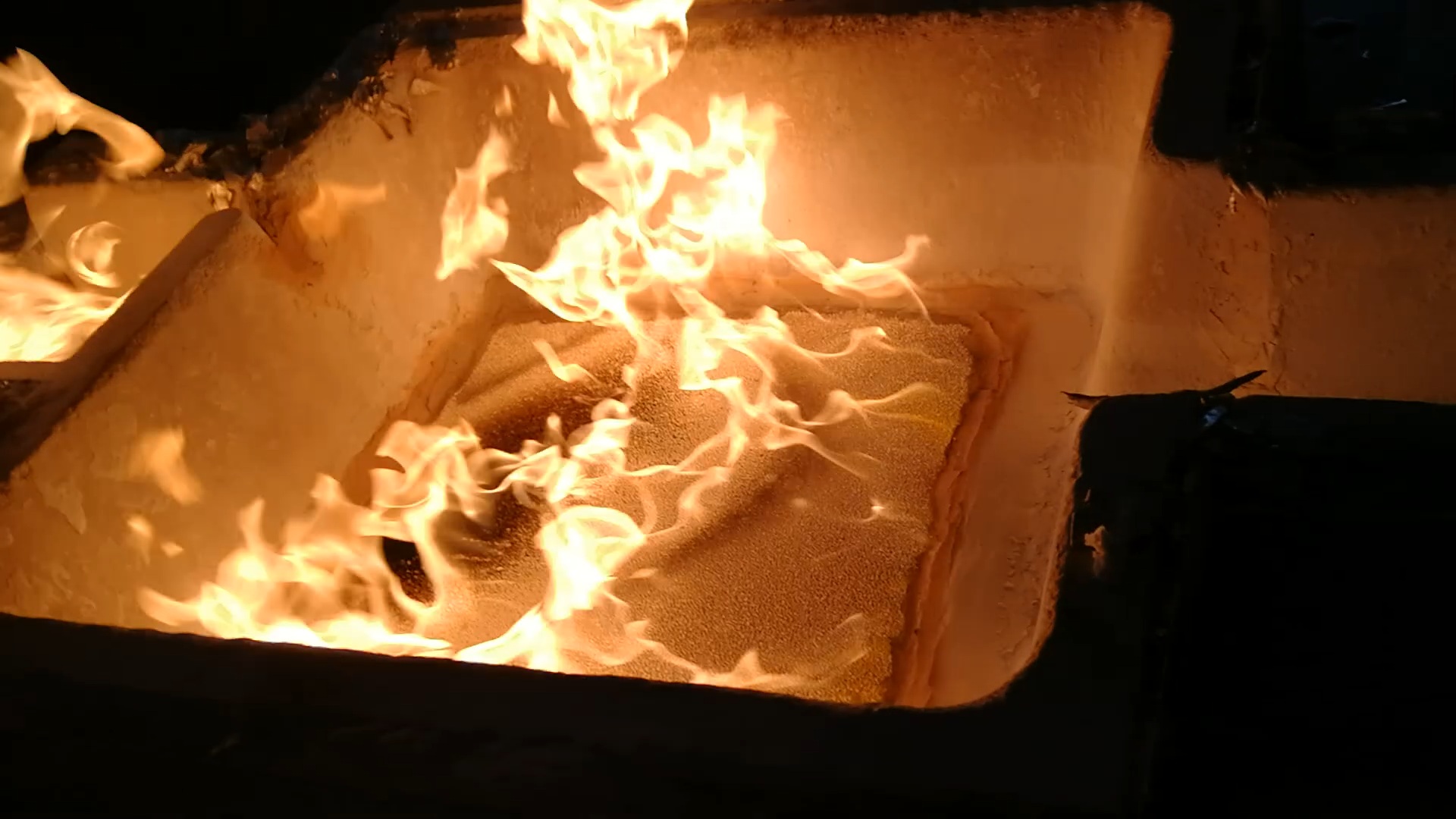

After pouring process, thermal shock properties, obtain from pouring liquid aluminum when filter was placed in the gating system to ensure that the China Ceramic Foam Filter CFF could withstand temperatures of aluminum alloys.

Then filter was cut into several sections to measure the macro and microstructure of the filter and ensure that impurity particles captured by a filter.

Further experiments were also done to investigate the efficiency of produced ceramic foam filter on quality of cast products.

The result obtained in this investigation, the mechanical properties for aluminum LM6 alloy sand casting increased when ceramic foam filter was inserted into the gating system.

A produced filter by using new materials is economical to produce.

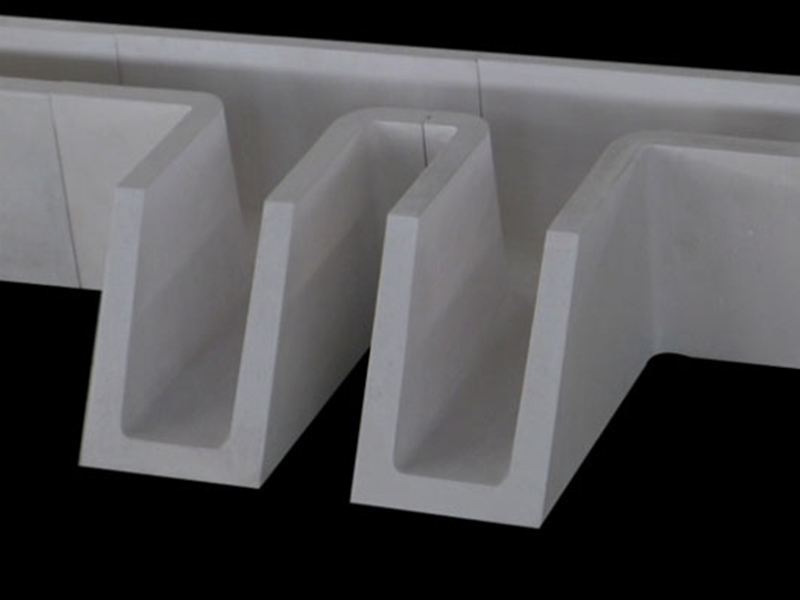

Further more, the analysis data shows present innovation filter which can be made in any shape and size, has excellent thermal shock resistance, and acceptable permeability properties.

China Ceramic Foam Filter CFF has the advantages of high prorosity, low loss of thermal shock, high mechanical strength at normal and high temperature, large specific surface.

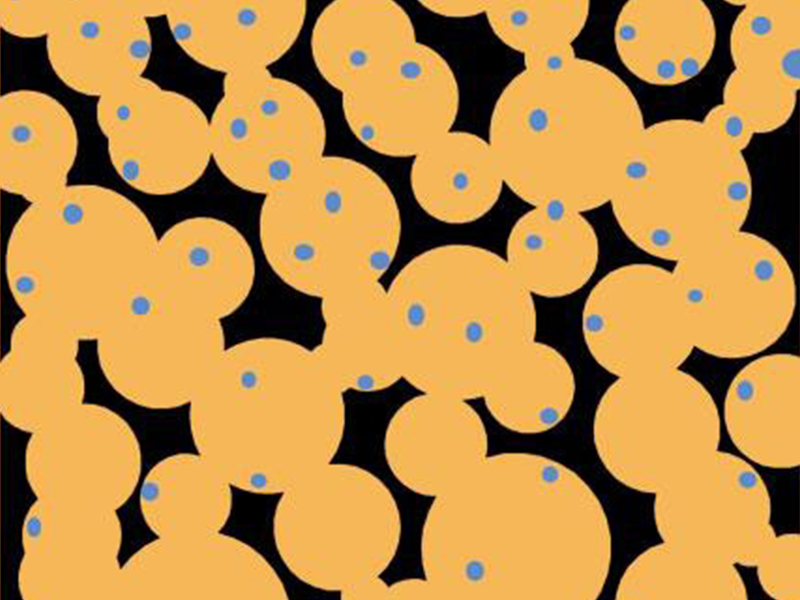

Good chemical stability and excellent filtering functions of screen, filtering residum collection and absorption especially for tiny impurity of 1~10um.

The three-dimension structure can improve the cast quality in large scale by changing the molten metal from turbulence flow to lamellar flow, removing the gas and smoothing the casting.

It is not only applied for molten metal filtering in high temperature, but gas treatment in high temperature, carrier of catalyzer, solid heat exchange and advanced filling for chemical industry.

With more than ten years of scientific research and development, FCRI has developed a series of ceramic foam filters which are made of different materials such as Aumina, Silicon Carbide and Zirconia.