Ceramic Foundry Filters Manufacturers Adtech said that the quality of the aluminum melt is very important, it greatly affects the subsequent processing performance and the quality of the final product. Therefore, all countries in the world very much wish to purify aluminum melt.

There are many reasons for aluminum pollution. On the one hand, in the melting process, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state, which is susceptible to oxidation, easy to react with water vapor to absorb hydrogen, and easy to form various forms of non-metallic slag (Such as lining fragments, chlorides, carbides in the flux, etc.) and coarse intermetallic particles, etc.

On the other hand, some of the waste materials that make up the furnace charge introduce some non-aluminum impurities during circulation.

Because the waste material comes from the process waste products, geometric waste materials and off-site waste materials of each process of the factory, the paths are different, the ingredients are complex, and the quality is also poor.

These impurities often cause bubbles and inclusions in the slab, which seriously affect the purity of the metal melt, thereby further affecting the processing performance, mechanical properties, corrosion resistance and product appearance quality.

Nowadays, there are various methods to remove these harmful substances and purify the aluminum melt.

According to different methods, these methods can be divided into two categories: in-furnace treatment and out-of-furnace continuous treatment (that is, on-line treatment).

According to the role, it can be divided into two types: mainly degassing or slag removal. Ceramic Foundry Filters Manufacturers (www.adtechamm.com) introduces the continuous filtration of aluminum melt using foam ceramic filter plates. Continuous processing outside, and the main purification operation is to remove slag.

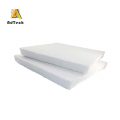

Ceramic Filter For Foundry has a network pore structure with a certain strength, can withstand the pressure difference of metal liquid level and the impact of metal flow, but it is brittle and fragile. Due to the precise structure of this material, the quality is uniform and has a large Surface area, so the filtration effect is excellent.

Foam Filter Manufacturers introduce Ceramic Filter Malaysia to purify aluminum liquid

1. Increase extrusion productivity

When using filter plates to purify 6063 alloy extruded billets, we followed up on a particular mold and found that the extrusion speed increased by about 20% and the productivity increased by nearly 15%.

2. Extend the life of the mold, and reduce the number of repairs.

3. Reduce squeezing force

When the filter plate was used to purify the 6063 alloy melt, the extrusion force was found to be more than 3% lower than the unfiltered.

4. Significantly improved the surface quality of aluminum profiles.

From the above. The use of foam ceramic filter plates to purify the aluminum melt has great advantages in reducing production costs and improving product quality.

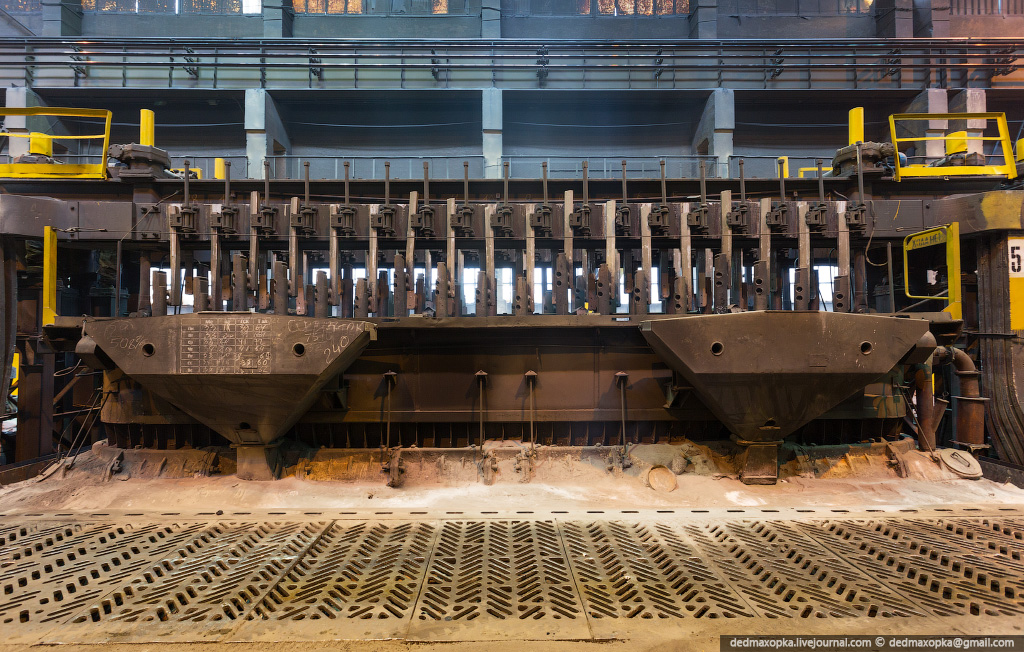

In addition, the ceramic filter plate is used to purify the aluminum liquid. The device is a common steel shell lined with prefabricated refractory brick pads. It is horizontally formulated in the metal launder, that is, between the runner and the casting well. Therefore, there is no need to make major changes to the existing casting system, and only a small space is required. And, a filter plate can effectively filter all the metal in one melting time, and it is very convenient to take out or replace it after using it.

It is also suitable for horizontal or vertical casting systems.