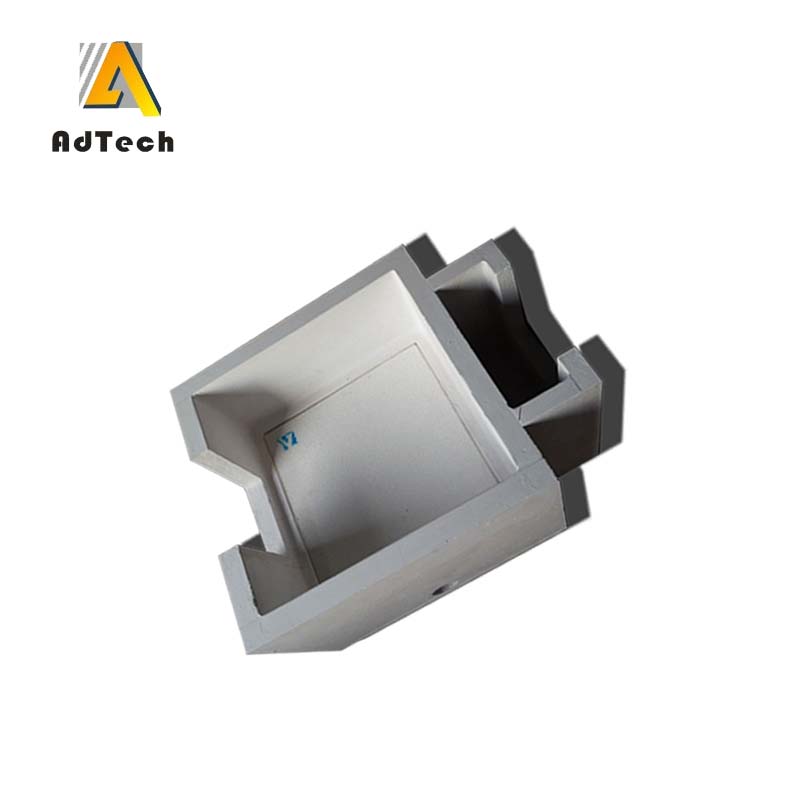

Ceramic Foam For Alumnia Casting

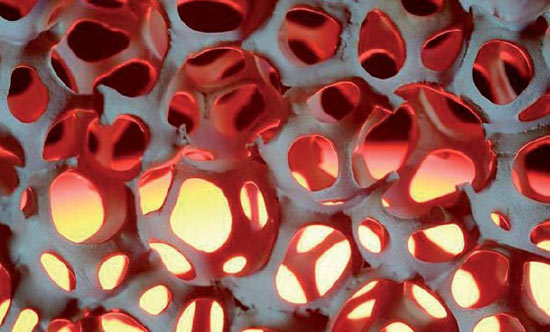

Ceramic Foam For Alumnia Casting utilizes a high porosity aluminum alloy/aluminum core alumina fiber composite foam preparation method, which belongs to the field of porous metal materials.

AdTech’s low strength for high porosity seepage aluminum foam is based on conventional seepage casting.

Two kinds of particles with different particle size range and aluminum fiber are used as the percolation precursor.

Through the uniform mixing, pressing, preheating oxidation and seepage of the percolation precursor, the percolating aluminum alloy/aluminum core alumina fiber with porosity of 75-90% is obtained. Composite foam.

The prepared aluminum alloy/aluminum core alumina fiber composite foam has the characteristics of pore structure, strength control, simple preparation process and low cost, and can realize industrial production.

Ceramic Foam Filter PAL Using three-dimensional network structure and connected pores organic foam as a carrier and immerse into thixotropic special Al2O3 molten material slurry, using four correction center distance and automatic extrusion, the slurry evenly deposited in the foam, after 1320 ℃ Drying and solidification.