Ceramic Foam Filtering System is used to filter and purify non-metallic impurities in molten aluminum, which is very important to ensure the quality of aluminum products.

Molten metal usually contains impurities in the form of inclusions, which are not removed during the refining process. In order to obtain advanced metal raw materials for thin plate manufacturing, fine wire drawing and precision casting, it is usually necessary to pass molten metal through a filter to remove these inclusions.

In particular, molten aluminum often contains entrained solids, which are harmful to the final cast metal product. These entrained solids appear as inclusions in the final cast product after the molten metal is solidified, and cause the ductility of the final product to decrease or the smoothness and anodizing properties of the final product are poor. Inclusions may come from several sources. For example, inclusions may come from a surface oxide film that is broken and entrained in the resulting molten metal. In addition, inclusions may come from insoluble impurities, such as carbides, borides, etc. or corroded furnace and trough refractories.

Provide reticulated organic polymer foam.

Impregnate the foam with the aqueous slurry.

Dry and heat the impregnated polymer foam to remove its organic components.

It is fired at a high temperature to produce the ceramic foam filter.

Ceramic Foam Filtering System uses elastic sealing devices or gasket-type seals to seal the filter plate in place. The seal surrounds the filter plate at the beveled corner of the filter plate.

The gasket seal ensures that there is no leakage in the installation and provides an effective separation medium, which is essential for easy disassembly.

In addition, since gaskets or sealing devices prevent metal from entering the sealing surface of the holder unit, their use greatly simplifies cleaning and effectively extends the life of the unit by eliminating the problem of metal corrosion.

In addition, due to its elasticity, the gasket can provide sufficient friction to fix the filter body in the proper position in the bracket or filter.

No need to use other types of compression devices.

The elastic sealing device should not wet the specific molten metal, resist its chemical corrosion, and should be fire-resistant enough to withstand higher operating temperatures.

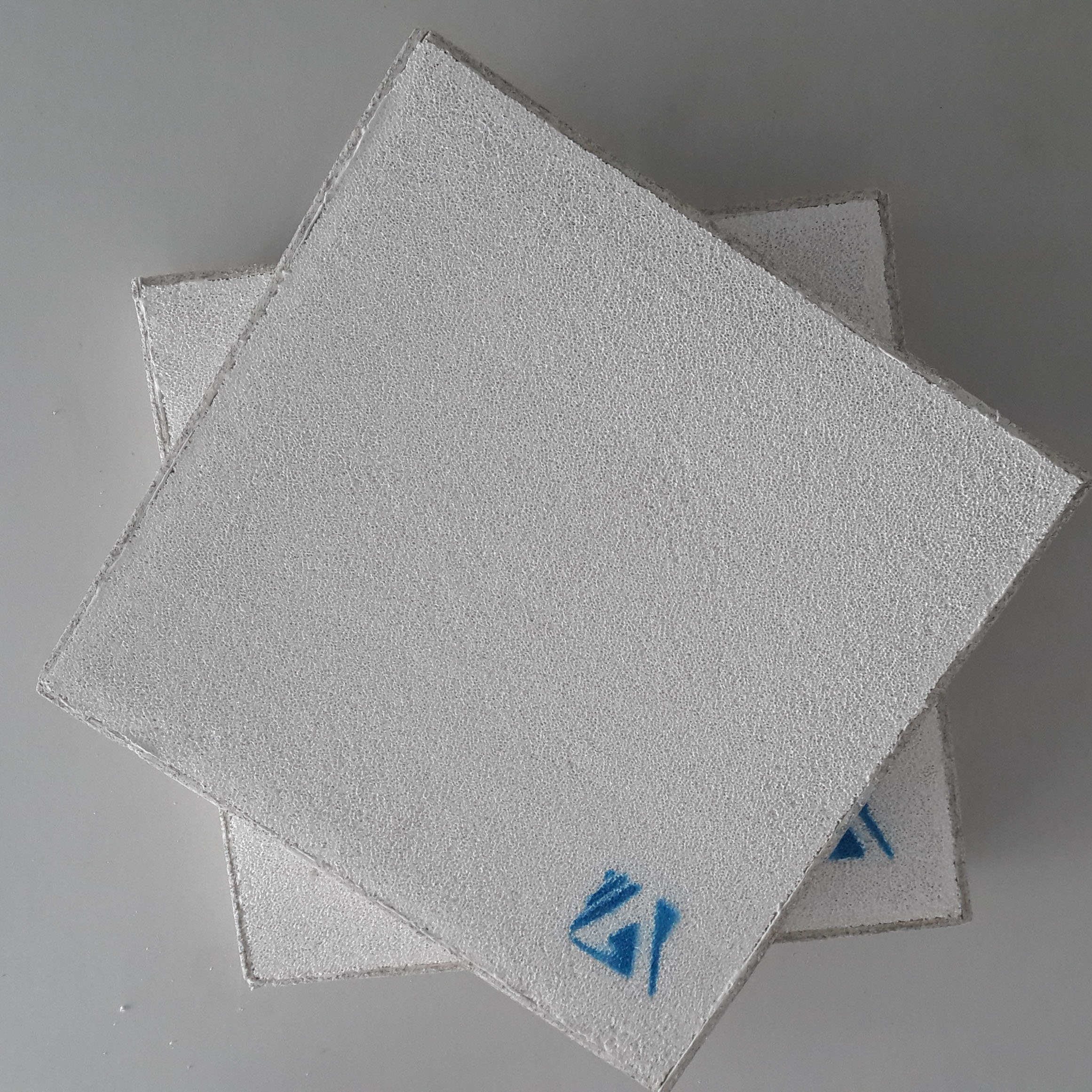

Ceramic foam filter Dimension

660x660x50(26 inch)

584x584x50(23 inch)

508x508x50(20 inch)

432x432x50(17 inch)

381x381x50(15 inch)

305x305x50(12 inch)

228x228x50(9 inch)

178x178x50(7 inch)

Foam Filter Manufacturers Email:sales@adtechamm.com

Ceramic foam filter Pore Size (PPI): 10/20/30/40/50/60

30ppi 40ppi Ceramic Foam Filtering is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

[…] filtration of impurities in the molten metal during the casting process is one of the key links. Ceramic Foam Filtering System for molten metal are used to remove inclusions and reduce turbulence. So as to achieve a fast and […]