Ceramic Foam Filter Wholesale plays a very important role in improving the quality of aluminum alloy melt, which greatly affects the subsequent aluminum and aluminum alloy processing performance and the quality of the final product. Therefore, all countries in the world attach great importance to the purification of aluminum melt.

There are many reasons for aluminum pollution

On the one hand, during the melting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-melted state, which is easy to oxidize, easily reacts with water vapor to absorb hydrogen, and is easy to form various forms of non-metallic slag (such as lining fragments, chlorides, etc.) The flux of carbides, etc.) and coarse intermetallic particles.

On the other hand, the charge of some wastes carries some non-aluminum impurities in the recycling process, because the waste comes from the process waste of each process, wastes our factory and the waste outside the factory, so the route is different, the composition is very complicated, and the quality is also difference.

These impurities often generate bubbles and inclusions in the slab, which seriously affect the purity of the molten metal, and further affect the processing performance, mechanical properties, corrosion resistance and product appearance quality.

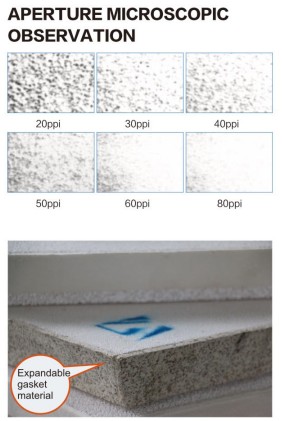

Ceramic Foam Filter Wholesale can effectively remove all kinds of inclusions in the aluminum water with a fineness of micrometers, and make the aluminum water form a stable laminar flow, which is conducive to filling; it has a unique mullite-corundum structure, good mechanical strength and chemistry Stability, excellent resistance to aluminum erosion; strict control of the pore size and through-hole rate can obtain a stable filtering effect; the foam ceramic filter plate is sealed with ceramic fiber gaskets, which helps to seal the filter plate in the filter box and ensure that there is no bypass.

Application of Ceramic Filter Malaysia

1. The purification process of molten metal in the production of aluminum and aluminum alloys.

2. In special fields and other applications under high temperature conditions, ceramic foam has excellent heat dissipation characteristics.

Ceramic foam filter Dimension

(26 inch)660x660x50

(23 inch)584x584x50

(20 inch)508x508x50

(17 inch)432x432x50

(15 inch)381x381x50

(12 inch)305x305x50

(9 inch)228x228x50

(7 inch)178x178x50

Ceramic foam filter Pore Size(PPI):10/20/30/40/50/60

30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.