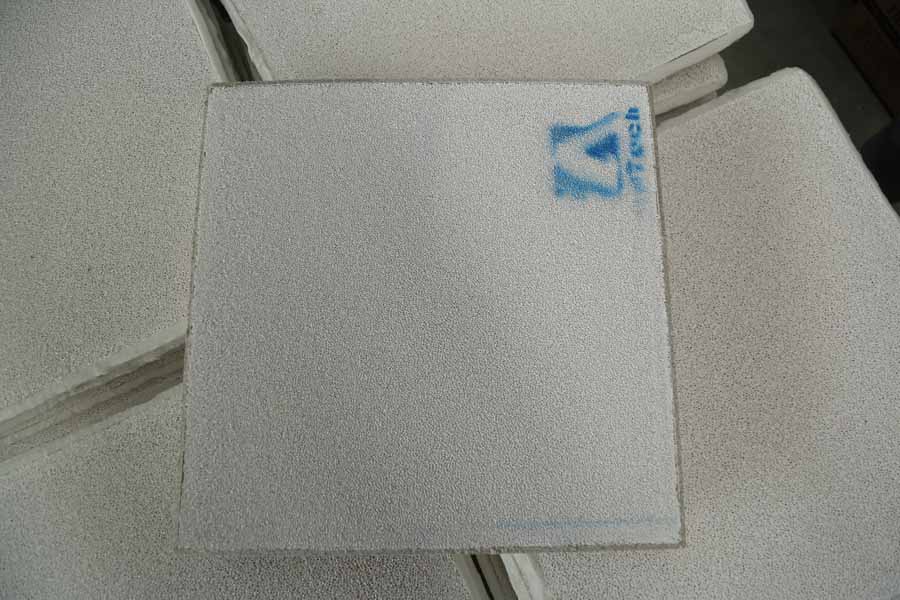

Ceramic Foam Filter Talco Aluminum is used as a filter medium for molten aluminum in the casting process to purify the liquid of the casting alloy and reduce or eliminate various non-metallic inclusions and exhaust problems during the casting process. Casting waste caused by casting defects (such as non-metallic inclusions) accounts for 50%-60% of the total number of waste products.

Install ceramic foam filters on the CFF filter equipment to filter liquid impurities in aluminum alloys to meet the production of high value-added, high-tech performance aluminum alloy precision castings such as aviation and transportation.

Aluminum and its alloys are prone to oxidation and gas absorption. In the smelting and casting process, and inclusions and other defects, pores are easily formed during the die-casting process, which is not conducive to the alloy structure, thereby reducing the mechanical properties and corrosion resistance of the alloy. And reduce production. Therefore, reasonable control of the smelting process and improvement of the quality of the aluminum melt are the key to improving the quality of aluminum die castings.

Ceramic Foam Filter Talco Aluminum Dimension

660x660x50(26 inch)

584x584x50(23 inch)

508x508x50(20 inch)

432x432x50(17 inch)

381x381x50(15 inch)

305x305x50(12 inch)

228x228x50(9 inch)

178x178x50(7 inch)

Ceramic foam filter Pore Size (PPI): 10/20/30/40/50/60

30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

TALCO ALUMINIUM COMPANY. A giant stride for Aluminium (Everything & Anything in Aluminium) is one of the leading Aluminium Manufacturer in the Industry today for Aluminium Sheets, Coils, Plates, Chequered Sheets, Roofing Sheets & Extrusion Profiles (Architectural & Structural Glazing Profiles, Electrical Sections, Transport Sections, Modular …