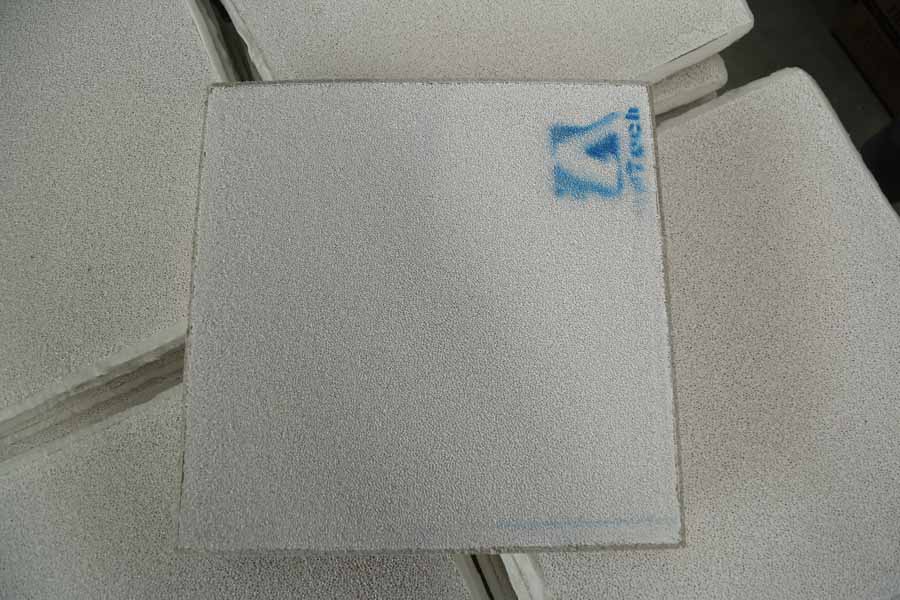

Ceramic Foam Filter Suppliers Product, as we all know, plays a very important role in the aluminum liquid purification system.

Ceramic Foam Filter can effectively remove the large inclusions in the aluminum liquid and effectively reduce the micro inclusion size of the micro inclusions, improving the surface quality and product performance.

Improve the role of the microstructure and increase the yield. As long as used in aviation, transportation and other aluminum alloy precision casting. Aiwensi ceramic filter plate adopts three-dimensional mesh structure and organic carrier connected with air holes to invade special thixotropy special ZrO2 quality molten materials, adopting four-square correct center distance automatic extrusion technology, so that the slurry is evenly applied to the foam of the carrier. On the skeleton, it is baked and cured at a high temperature of 1680°C and has an expanded cotton body sealing edge.

The specifications of ceramic filter plates supplied by our company

7in, 9in, 12in, 15in, 17in, 20in, 23in, 26in

Ceramic Foam Filter Suppliers Product Dimension

660x660x50(26 inch)

584x584x50(23 inch)

508x508x50(20 inch)

432x432x50(17 inch)

381x381x50(15 inch)

305x305x50(12 inch)

228x228x50(9 inch)

178x178x50(7 inch)

Ceramic foam filter Pore Size(PPI):10/20/30/40/50/60

30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.