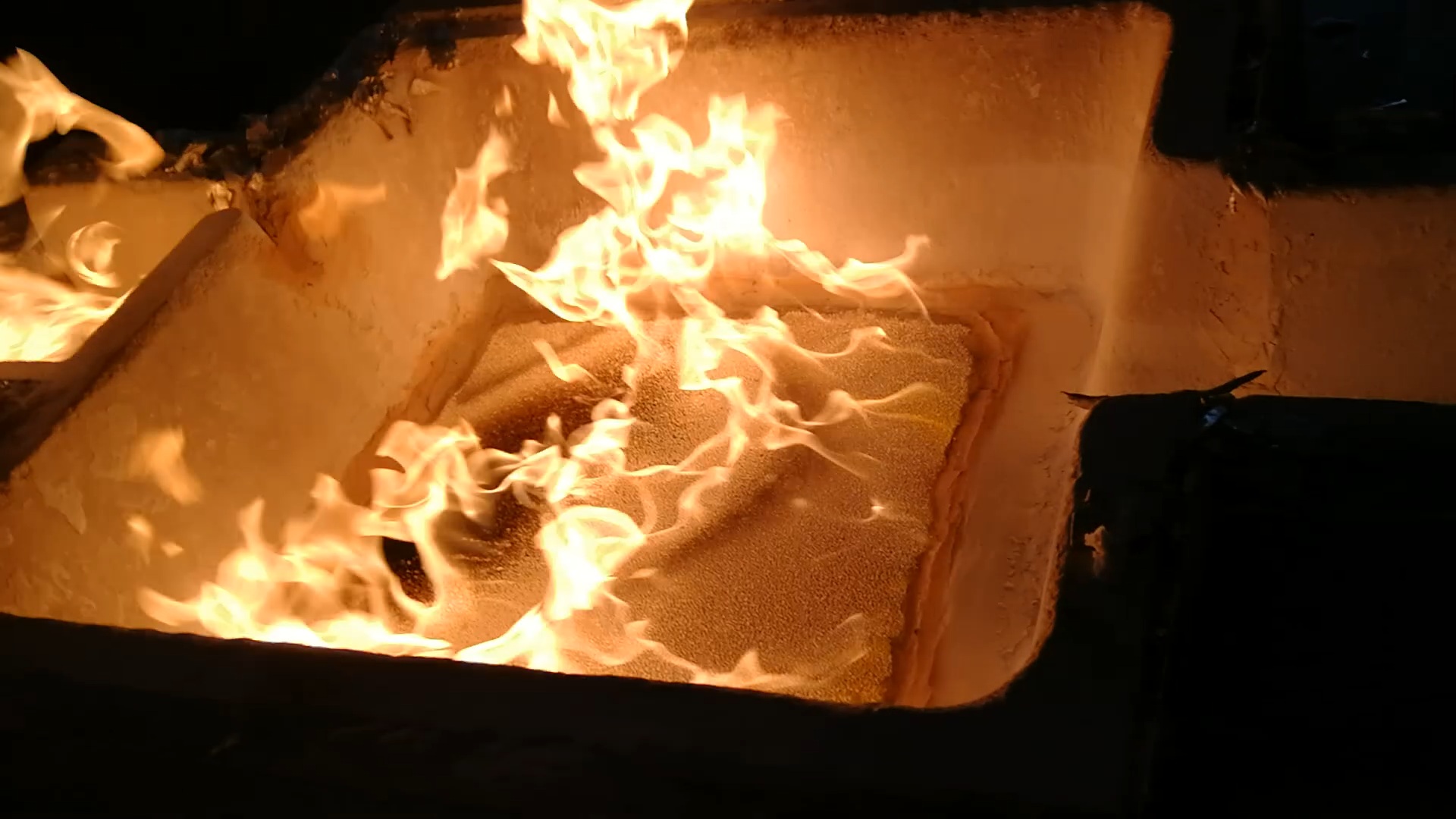

Ceramic foam filter removes inclusions in aluminum melt

Ceramic Foam Filter can effectively remove the inclusions of the aluminum melt and significantly improve the quality of aluminum products. So as to greatly improve the production of aluminum products.

Aluminum products play an important role in the daily lives of residents.

In the early production process of aluminum products, due to the imperfection of its own process methods, there was a large amount of aluminum oxide residue in the electrolytic aluminum liquid, which seriously affected the quality of aluminum products.

In the modern aluminum melting and casting industry, in the process of producing aluminum products, Ceramic Foam Filters can effectively improve the alumina impurities in the aluminum liquid and increase the quality of aluminum products.

The chemical composition of the non-metallic inclusions formed in the aluminum melt is very stable, and it is easy to cause cracks in the castings after solidification.

The presence of non-metallic inclusions makes it difficult to predict the mechanical properties of castings.

The influence of oxidized inclusions on the tensile properties of aluminum alloys is believed to be the main cause of the decrease in the mechanical properties of aluminum alloys.

Stable and clean aluminum melt has many advantages.

For example, it reduces the entrapment and solidification shrinkage during forming and increases the compactness and strength of the blank.

Improve the uniformity of blank performance.

The forming resistance is reduced, the production efficiency is improved, and the rejection rate is reduced.

Reduce the filling temperature and extend the life of the mold.

The blanks of complex parts can be manufactured, and the production can be highly automated. This technology has been successfully applied to the manufacture of aircraft engine blade parts.

Whether from an economic point of view or from a process stability point of view, in metal forming, there are many ways to provide aluminum alloy blanks, such as mechanical stirring method, electromagnetic stirring method, strain activation method, powder method, etc.

However, the only high-stability and ultra-clean aluminum alloy metal blank production technology for commercial applications is electromagnetic stirring and strain activation.

Electromagnetic separation is an efficient, stable, and clean method to remove non-metallic inclusions in the aluminum melt.

Among the various electromagnetic separation schemes, the alternating magnetic field scheme is the most suitable for the removal of tiny inclusions.

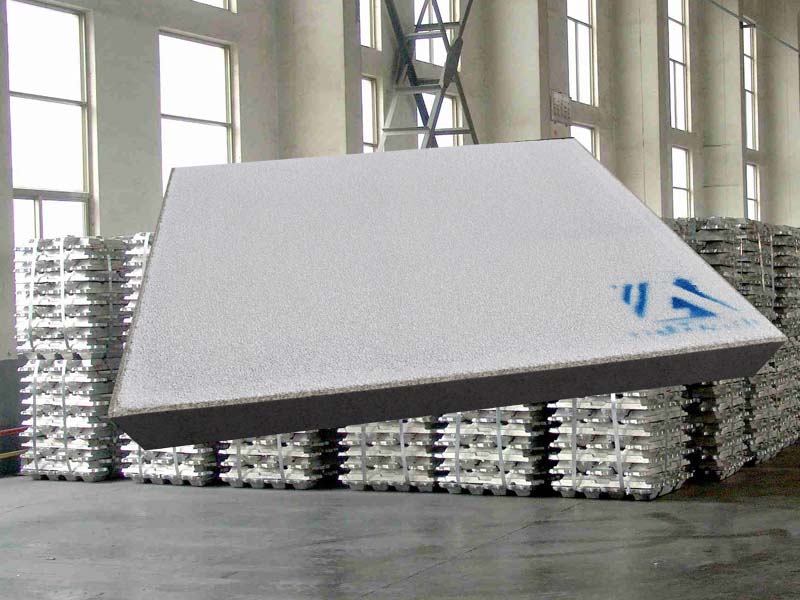

I is expected to become a net exporter of aluminum after 2019

Starting in 2019, it is expected to become a net exporter of aluminum. An official of the Iian Mining and Mining Industry Development and Innovation Organization said at the Arab meeting held in Oman. However, in the short term, I will still maintain its status as a net metal importer. I’s current aluminum production capacity is 457,000 tons/year, operating capacity is 437,000 tons/year, and aluminum production is about 340,000 tons/year.

At present, I’s domestic alumina production is in a state of shortage, and talks with Chinese companies are being held to build an alumina smelter with an annual capacity of 2 million tons in Asaluyeh. The bauxite required by the smelter will be imported from I’s long-standing supplier, the Guinea Alumina Company in Conakry. I has reached an agreement with the company that as of 2040, I can mine 4 million tons of bauxite from Guinea every year.

If things go on like this, I will reach a balance between domestic aluminum production and demand in the past five years, and eventually become a net exporter of aluminum.

I is currently planning to increase domestic aluminum production to 1.5 million tons in the next 15 years.