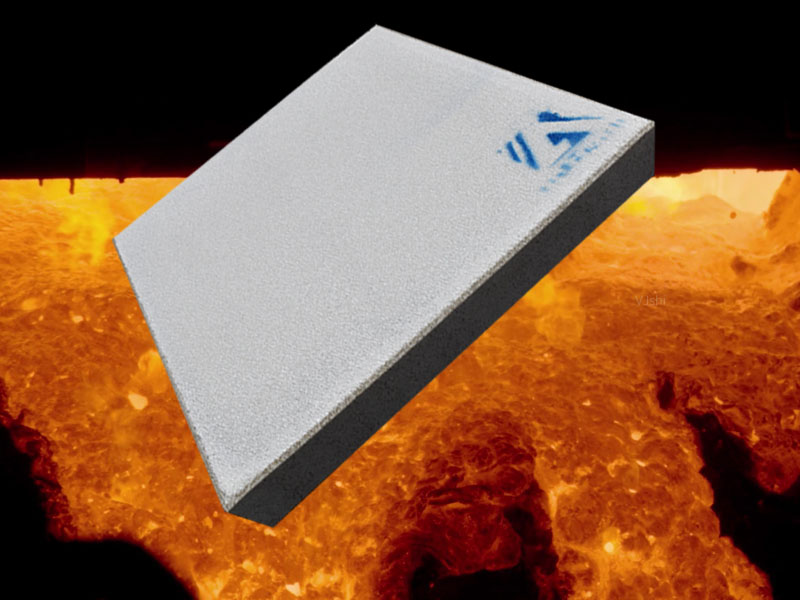

Ceramic Foam Filter Mozal Aluminium can remove small inclusion particles of 10-25um in molten aluminum.

However, in the presence of a large number of inclusions, too fine sieve holes will cause clogging, thereby shortening the service life of the filter. Therefore, the aluminum ingot factory should choose a reasonable model according to the corresponding process requirements.

Mozal Aluminium engineer introduced the selection of Ceramic Foam Filter

Ceramic Foam Filter Mozal Aluminium (PPI): 10/20/30/40/50/60

30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

Keywords=Molten Aluminum Filter, Ceramic Foam Filters, Ceramic Filter Plate, Porous Aluminum plate, Silicon Carbide Ceramic Foam Filter, Alumina Ceramic Filter, Alumina Foam Filters, Molten Metal Filtration, Cast House Filter, casting filter.

Mozal Aluminium introduces the cleanliness of liquid aluminum

That is, reducing the entry of molten aluminum inclusions is a very important factor in the production of high-quality products.

The inclusions in the aluminum alloy cause the alloy structure to be disconnected, reduce the compactness of the product, cause corrosion and cracking, and reduce the mechanical properties of the final product.

With the gradual development of aluminum industry applications, products have higher and higher technical requirements for melt processing. The production of green aluminum requires melt processing equipment to comply with environmental protection policies.

Only by continuously improving our aluminum smelting and refining equipment and technology can we meet the higher quality standards of users and maintain continuous competitiveness in the production of high-performance and high-quality materials.

AdTech is committed to continuously improving melt processing and control technology, providing a complete set of melt purification equipment, and adopting green technology to achieve environmentally friendly, efficient, and sustainable development of the aluminum processing industry.

For the processing of molten metal, it is necessary to remove foreign intermetallic inclusions, such as impurities in raw materials, slag, foam, and oxides formed on the surface of the melt, and small refractory materials used to form alloys.

A chamber or container in which molten metal is formed.

Removal of these inclusions will form a uniform melt, thereby ensuring high product quality, especially in steel, iron, and aluminum metal castings.

Today, ceramic filter devices are widely used because of their ability to withstand extreme thermal shocks due to their resistance to chemical corrosion and mechanical stress.

MOZAL Aluminum Plant once again ranked among the top 100 companies in Mozambique and was named the largest company in Mozambique for the sixth consecutive year.

Australia’s BHP Billiton Group has a majority stake in the aluminum plant.

In second place is the Cabra Bassa hydroelectric power station, the government of Mozambique holds a majority stake in the hydroelectric power station.

The Mozambican Telecom Company (MCEL)’s ranking rose from fourth to third, while Mozambique’s Petronas dropped from third to fourth.

Mozambican Electric Company, Mozambique Beer Company, and BP Mozambique are ranked fifth, sixth, and seventh in the order.

Mozambique International Bank rose from ninth to eighth, Motraco rose from eleventh to ninth, and Sasol Petroleum Taimani fell from eighth to tenth.