Ceramic Foam Filter Komi Aluminium Project attaches great importance to the purification of aluminum melt. There are many reasons for aluminum pollution. Foam ceramic filters are no stranger to people in the aluminum casting industry.

Ceramic Foam Filter adopts the principle of adsorption, which can effectively remove large inclusions in molten aluminum and effectively adsorb small inclusions of small size.

Aluminum is in a molten or semi-melted state during the smelting process, and some of the waste materials constituting the charge will introduce some non-aluminum impurities during the recycling process.

The ingredients are complex and the quality is poor. The above-mentioned impurities often generate bubbles and inclusions in the slab, which seriously affect the quality of gold, and further affect the processing performance, mechanical properties, corrosion resistance and product appearance quality.

The Ceramic Foam Filter Komi Aluminium Project can effectively remove micron inclusions in the aluminum water and make the aluminum water a stable laminar flow.

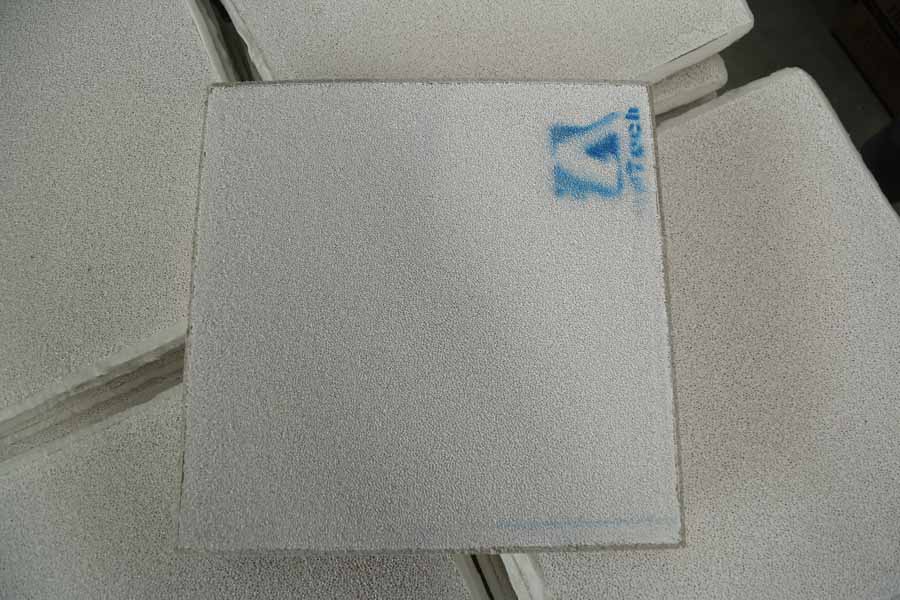

It has a unique corundum structure, good mechanical strength and chemical stability, and a stable filtering effect. There are sealing ceramic fiber gaskets around the ceramic filter plate, which helps to seal the filter plate in the filter box and ensure that the metal liquid is not lost.

In 2006, RUSAL Aluminium acquired the assets of Guyana’s state-owned Aroaima Mining Company, acquired the remaining shares of the Friguia bauxite and alumina complex in Guinea, completed the large-scale transformation of the Armenal foil plant and entrusted the Khakas aluminum smelter to Russia, the world’s largest aluminum smelter. One of the most advanced aluminum production facilities. RUSAL also acquired a 56.16% stake in the Sardinian alumina refinery Eurallumina.

In May 2006, RUSAL and RusHydro signed a cooperation agreement for the construction of Boguchanskaya Hydropower Station (HPP) and Bogushansky Aluminum Smelter. In November 2006, RUSAL refined alumina from Bratsk, Krasnoyarsk, Sayanogorsk and Novokuznetsk aluminum smelters, Achinsk and Boksitogorsk The ownership of the plant and the Russian State Aluminum Magnesium Research Institute (VAMI) increased to 100%, and the ownership was increased in Sayanar in June 2007.

In order to remain competitive, VAMI and SibVAMI Aluminum and Magnesium Institute became the backbone of the engineering and technology center, participating in the development of new and unique production technologies, including RUSAL’s RA-300 and RA-400 electrolyzers. The new technology allows large-scale greenfield and brownfield projects. In 2005, Rusal created its own engineering and construction subsidiary Rusal-Engineering Development Limited, responsible for modernization and construction projects.

In December 2006, RUSAL acquired a 77.5% stake in the Nigeria Aluminum Smelting Company (ALSCON) through a privatization process. In January 2008, the group further acquired a 7.5% stake in ALSCON from MAN Ferrostaal AG.