Ceramic Foam Filter Kiez Technology

The invention relates to methods for ceramic foam filters (PCF) for the purification of liquid aluminum and its alloys. It can be used in metallurgy, foundry.

A known method of manufacturing foam ceramics for refining metals, including the impregnation of porous materials with ceramic slip of the following composition, wt. %: finely ground dunite, forsterite or marriage of forsterite products (60-80) and a finely ground mixture of periclase or marriage of periclase products and clay in a ratio of 80: 20-90: 10-20: 40. In this case, the firing of ceramic foam is carried out at temperatures of 1200-1750 ° C, and its duration is not shown.

The disadvantages of the method include high energy costs for its implementation.

A known method of manufacturing a filtering ceramic foam, which includes the impregnation of organic foam with ceramic slip, containing, by weight. %: aluminosilicate dust from electrostatic precipitators based on Al2O3 (30-90), magnesite sludge (0.5-20), K2O (2-8), SiO2 (4-40), metallurgical fine slag or a mixture of iron salts II and III and gallium – the rest.

Slip-impregnated organic foam preforms are dried at a temperature of 250-300 ° C and fired at temperatures of 1200-1600 ° C.

The duration of the drying and firing operations is not given.

The disadvantages of the method include the multicomponent composition of the slip and high energy costs for its implementation.

Closest to the invention is a method for the production of filter foam ceramics for cleaning, including aluminum and aluminum alloys, from slag inclusions, including impregnating a three-dimensional polyurethane mesh with a slip, removing its excess, drying the samples at temperatures of 18-25 ° C for 6-8 hours, at temperatures 100-150 ° C up to 2 hours and quenching at temperatures 450-500 ° C up to 3 hours.

The slip according to this method has the following composition, wt. %: high-modulus liquid glass (50-75), aluminum hydroxide (20-40), high-alumina cement or corundum up to 30, industrial carbohydrates (3-5), industrial water in the amount necessary to obtain the optimal consistency.

Ceramic Foam Filter Kiez Technology

The disadvantages of the method include the multicomponent composition of the slip, the high duration of the drying operation, the use of expensive materials based on Al2O3, the technological need for fine joint grinding of all components of the dry mixture, the need for holding the product at temperatures of 450-500 ° C for 3 hours.

The objective of the proposed solution is the expansion of the raw material base of suspension fillers for the production of PCF through the use of inexpensive and affordable materials – industrial waste in the form of a finely ground battle of steel casting ceramic shells using investment casting of quartz nature.

EFFECT: production of a slurry based on quartz, which provides PCF for processing aluminum melt with sufficient resistance to temperature effects, does not change its volume when heated, excludes the sintering operation during firing of the finished product, which maintains operability during possible chemical interaction of SiO2 with aluminum from the melt and eliminating the harmful effects of iron on the processed aluminum melt.

Ceramic Foam Filter Kiez Technology

The technical result is achieved by the fact that in the method of manufacturing Ceramic Foam Filter, including impregnating a three-dimensional polyurethane mesh with a slip, removing its excess, drying the samples, heating to 450-500 ° C, drying is performed at a temperature of 65 ° C for 30 minutes, after burning out the polyurethane foam base the remaining slurry layers are applied, followed by drying between the layers for 30 minutes at a temperature of 65 ° C, and a finely ground fight of ceramic shell molds of steel casting is used as a filler of the slip yplavlyaemym models.

A slip for the manufacture of ceramic foam filters includes a quartz filler of nature in the form of finely ground (less than 50 microns) battle of ceramic cast steel shells according to investment casting, contains water and liquid glass as a binder.

The elemental composition of the finely ground battle of ceramic shells, determined by microprobe x-ray analysis with an energy dispersive spectrometer.

The peculiarity of the finely ground battle of ceramic shells is that it has a stable elemental composition, guaranteed by the constancy of the materials used according to the LVM technology and, possessing the SiO2 formula, is practically not prone to polymorphic transformations. All of them have already passed in marshallite and quartz sand when casting steel using the LVM technology at pouring temperatures of 1550-1630 ° C into molds heated to 900 ° C.

Ceramic Foam Filter Kiez Technology

In this regard, the subsequent heating of the finely ground battle of ceramic shells should not cause changes in volume, stress and cracks in products from it. For the same reason, finished PCFs do not need to be fired, and their high-temperature processing is reduced to burning out the polyurethane foam base at temperatures of 450-500 ° C. An exposure at this temperature is not required, since when a value of 500 ° C is reached, the polyurethane foam frame is removed.

The possible chemical interaction of SiO2 with aluminum from the melt being processed can not be taken into account, since the process of reducing silicon from its aluminum oxide requires much longer time than it takes to fill the mold through PCF.

The small mass fraction of iron in the finely ground battle of the ceramic shells of a steel LAN does not adversely affect aluminum melts when they are filtered through PCF.

In addition to the above, the use of finely ground battle of ceramic shells in PCF production technology contributes to the development of resource conservation in the foundry industry, industrial waste recycling technologies, and the raw material base of foundry and metallurgical technologies.

The battle of ceramic shells of a steel LAN used as a slurry filler had the following properties: bulk density 2350-2360 kg / m3; humidity 2-3%; pH = 6; mass change during annealing 1%; hygroscopicity of 0.5-1%. The material belongs to the 4th hazard class.

Finely dispersed powder was obtained from the battle of ceramic shells of a steel LAN using crushing and grinding operations. Pieces of battle of ceramic shells with an initial size of 20-50 mm were crushed in a jaw crusher to a maximum size of 10 mm. Further, the material was crushed in the IVCh-3 vibration abraser to the size of 50 microns declared by the equipment manufacturer.

Ceramic Foam Filter frame with dimensions 50 × 50 × 22 mm was prepared from a highly porous cellular material (HPLM) of the PPU-EF type (elastic polyurethane foam) [4] with the number of pores per inch of surface PPI 10.

The slurry was prepared by mixing ground battle of ceramic shells, liquid glass and water in the ratios shown in table 2. Liquid glass was used with a density of 1450 kg / m3.

A polyurethane foam frame was immersed in a slip of composition with a density of 1700-1750 kg / m3 and allowed to soak. Excess slip was removed using a rolling roll.

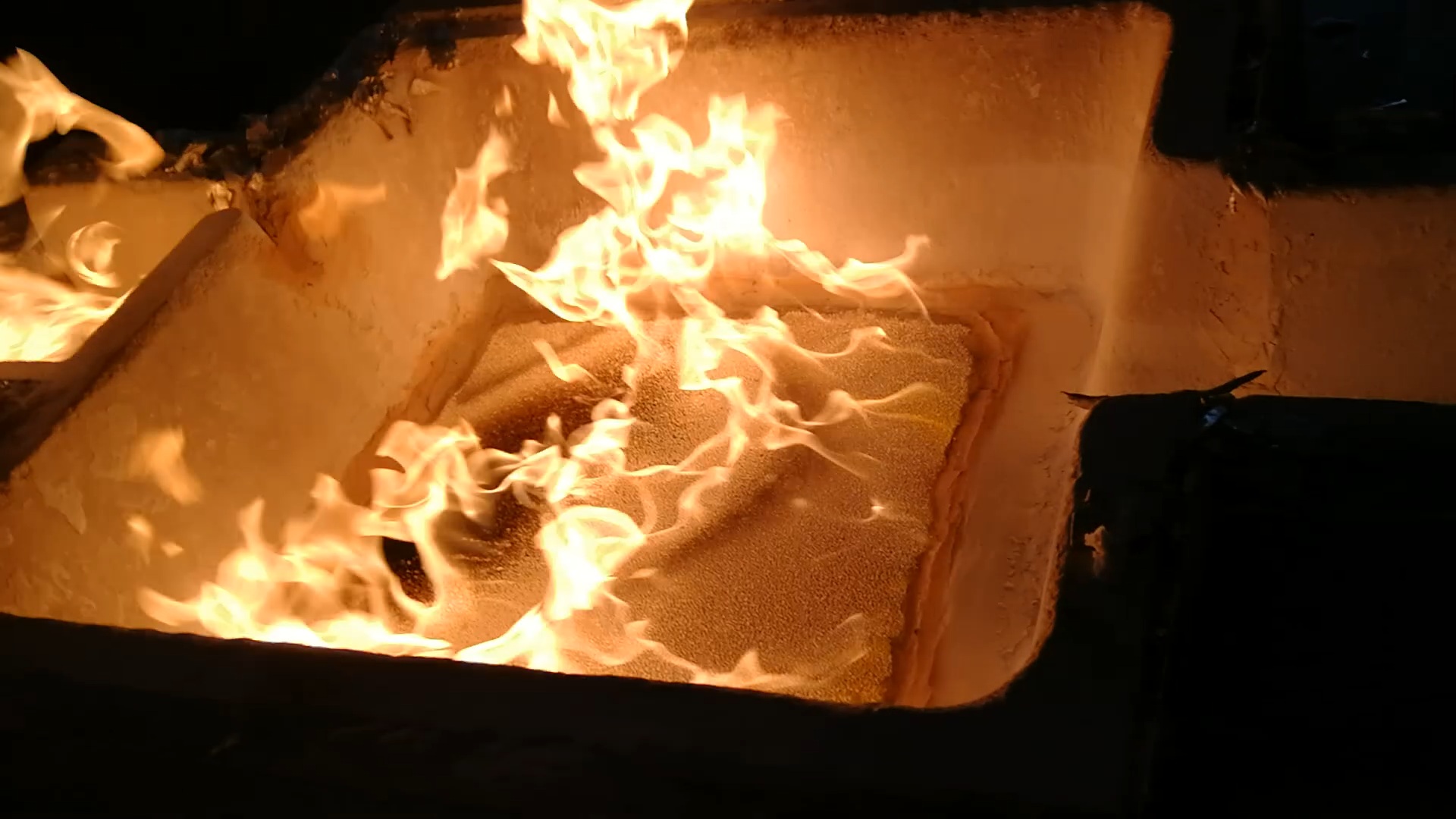

The workpiece was dried at 65 ° C for 30 minutes in a laboratory dryer. Then it was still warm and placed in a resistance muffle furnace heated to a temperature not exceeding 200 ° C, gradually raising the temperature to 450-500 ° C to burn the HPLC frame.

Exposure of the billet in the furnace at these temperatures is not required, since the frame from HPLC is completely removed when it reaches 500 ° C.

After removing the preform from the furnace and cooling it in air to room temperature, the resulting ceramic frame was immersed.

The slurry was allowed to drain and low pressure compressed air was purged to open the pores.

The preform was then dried at 65 ° C for 30 minutes in a laboratory dryer.

After this, the operations of applying the suspension and drying were repeated for the second and subsequent reinforcing layers.