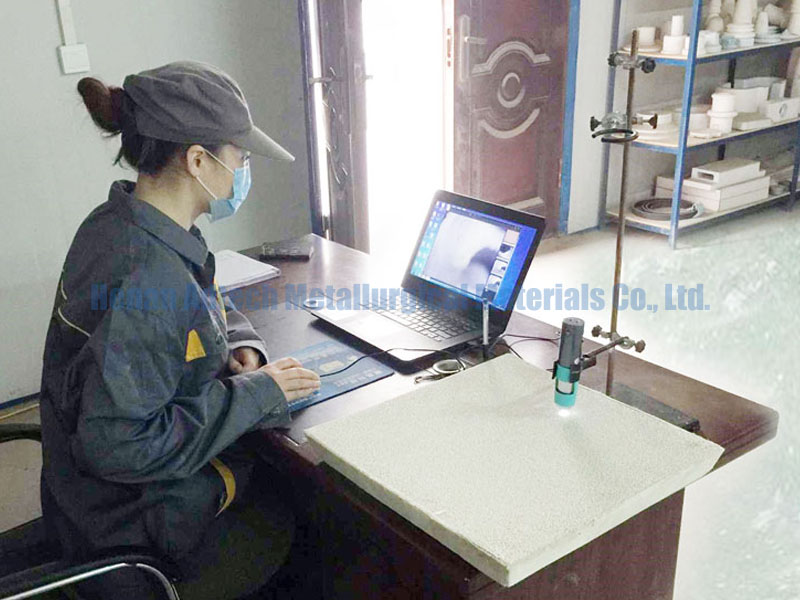

Ceramic Foam Filter is Crucial for Metallurgical Industry

Metals and metallic products have a special connotation with human civilization. It is considered to be one of the primitive material that human have mastered to use. However, all metals are not very stable in its rawest form. This form of metals may not have the optimum metallic properties and therefore it requires purification. Purification process of molten metal require ceramic ceramic foam filter, which ensure that all the impurities has been removed from the metallic solution. Once this process is achieve, metal is ready to be used in different types of applications through different processes.

As per the accepted industry standards, ceramic foam filter have few basic property which ensure easy purification of molten metal. These porous components plays very important role in this entire process, therefore it must have the standard properties.

Compressed strength The amount of raw material used during the purification process is very high, as doing this process in small quantities is not a cost effective solution. Therefore, heavy amount of metallic solution is poured over these filters and therefore it must have a high compressed strength to undergo the operation undamaged.

Essential Properties of Ceramic ceramic foam filter

Natural melting points of various metallic elements are very high. The range of melting point of metals may vary but generally is around few hundred to more than thousand degrees Celsius. It is therefore very necessary that ceramic foam filter must have certain properties. Here are some useful properties

Porosity It is the percentage of the pore space in the filter. This property is very important in operations as a filter with much larger or smaller porosity can hamper the process. Therefore, it is recommended that porosity must be ideal in terms of the types of molten metal used.

Purification process is very critical one; therefore every instrument must be in the best of shapes.