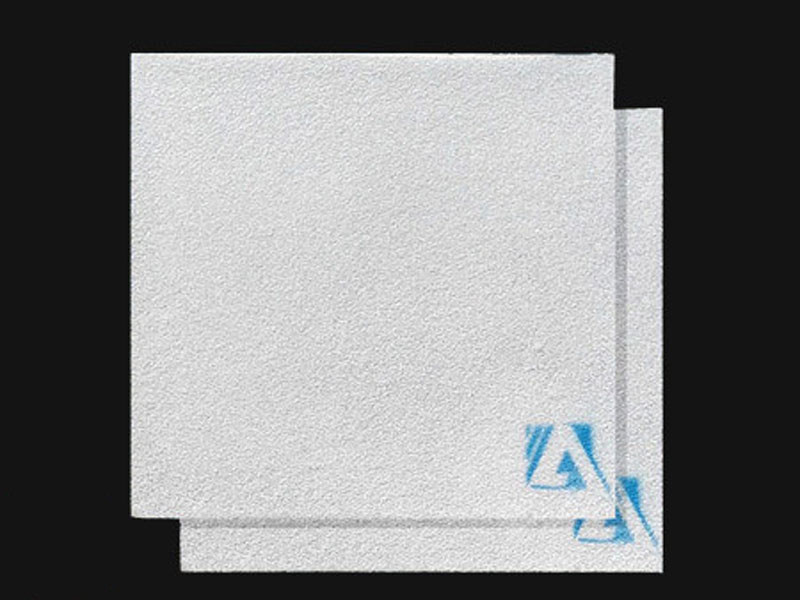

Since 2012, AdTech Metallurgical Materials Co., Ltd’s ceramic foam filter has been focusing on the research, development, production and marketing of adhesive ceramic foam filter (CFF) for aluminum alloy casting.

Ceramic Foam Filter For Liquid Aluminum adopts the principle of adsorption, which can effectively remove large inclusions in molten aluminum and effectively adsorb small inclusions.

No debris falls off, effectively reducing the pollution of molten aluminum.

Excellent thermal shock resistance, improve the erosion resistance of molten metal.

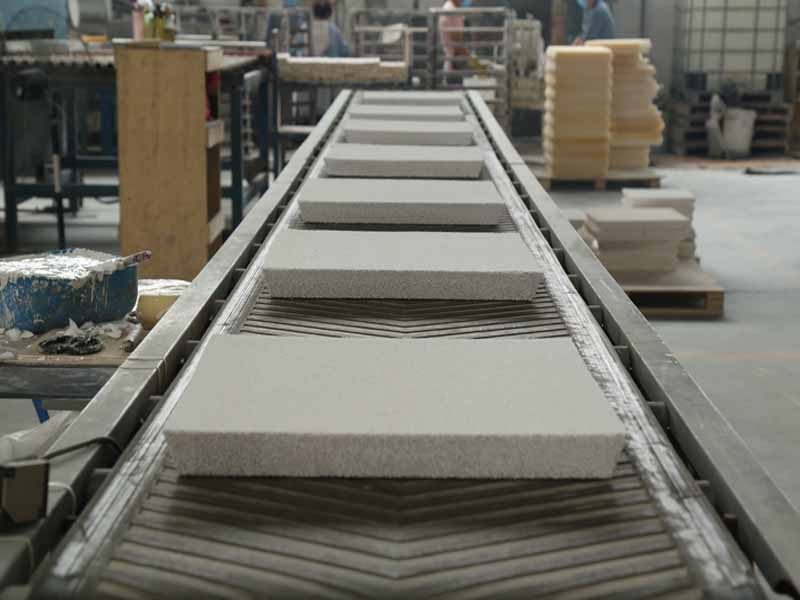

Automated production, 3 calibration procedures, precise dimensions, and tightly installed filter bowls.

Improve surface appearance and performance, purify molten aluminum.

The natural melting point of various metal elements is very high. The melting point range of metals can vary, but is usually around a few hundred to several thousand degrees Celsius. Therefore, it is very necessary for Asian foundry filters to have certain characteristics.

Aluminum preparation method

In 1854, the French chemist Deville mixed bauxite, charcoal, and table salt, and then heated it with chlorine gas to obtain NaCl, AlCl₃ double salt, and then melted the double salt with excess sodium to obtain metal aluminum.

In 1886, Howe of the United States and Hylandt of France independently electrolyzed a mixture of molten bauxite and cryolite (Na3AlF6) to produce metallic aluminum, laying the foundation for large-scale aluminum production in the future.

Liquid aluminum, that is, high-temperature liquid aluminum. When water flows into this molten aluminum, the water will rapidly vaporize and expand due to high temperature. This violent expansion of water vapor is an explosion. Under the action of the explosion caused by the high temperature of the water, the molten aluminum splashes, which will have more serious consequences.

The porosity of Ceramic Foam Filter For Liquid Aluminum is the percentage of pore space in the Cff of China Ceramic Foam Filter For Liquid Aluminum.

This property is very important in operation, because filters with much greater or lesser porosity hinder the process.

Therefore, it is recommended that the porosity must be ideal in terms of the type of molten metal used.

Ceramic Foam Filter For Liquid Aluminum is mainly used for the filtration of aluminum and alloys in foundries and foundries. Due to its excellent resistance to erosion and corrosion by molten aluminum, the filter can effectively remove inclusions, reduce residual gas and provide laminar flow, so the filtered metal can improve the quality of castings, reduce waste and reduce inclusions. Defects, all of which help increase profits.

-Reduce waste related to inclusions.

-Reduce costs related to inclusion of defects.

-Improve productivity through higher extrusion or rolling speeds.

-Increase casting flexibility, easy to replace alloy.

-There is no fixed metal.