Ceramic Foam Filter Casting Filtration

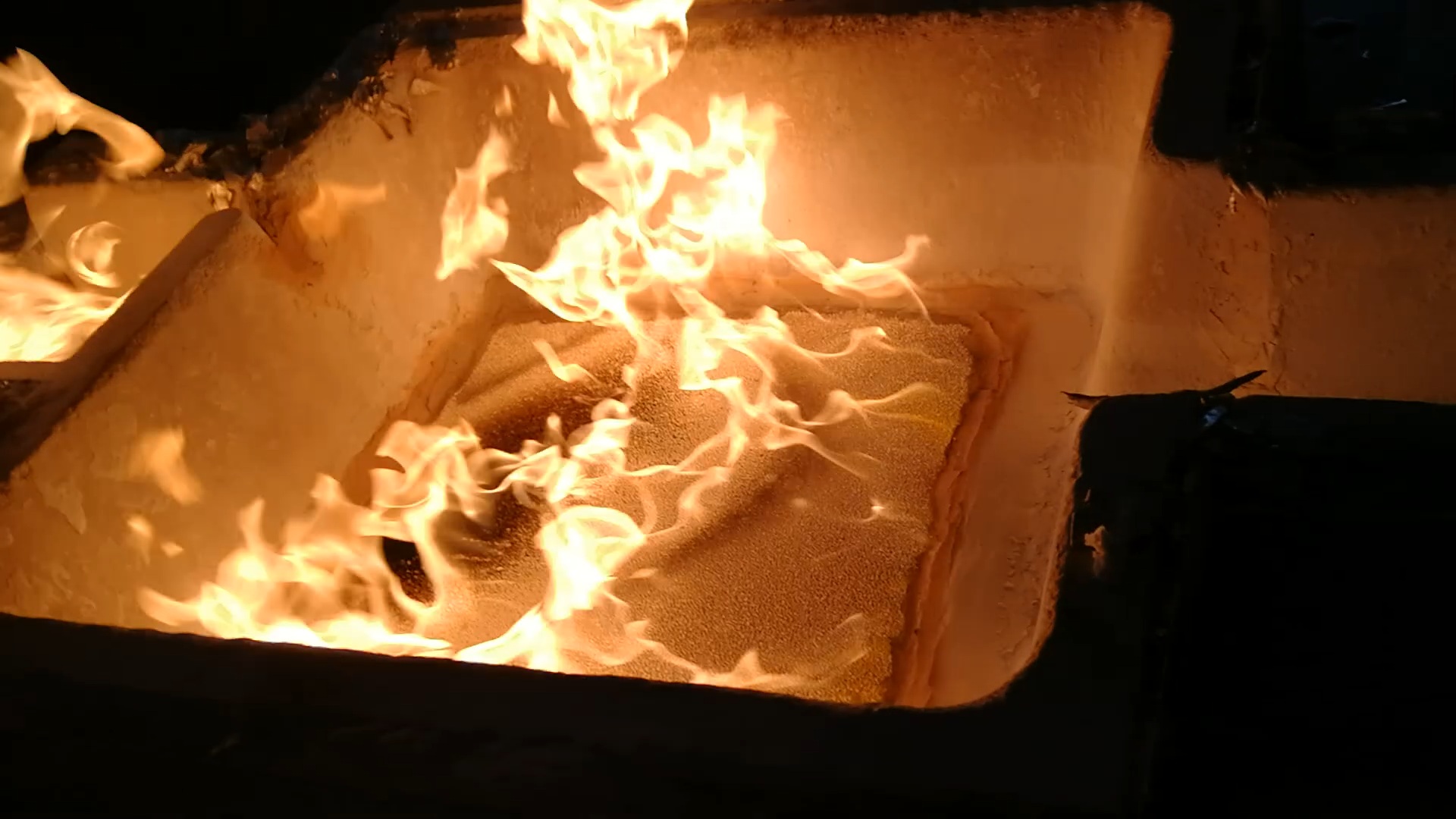

Ceramic Foam Filter Casting Filtration is mainly used for filtration of aluminium and aluminium alloys in foundries and cast houses. With excellent thermal shock resistance and erosion resistance, they can effectively eliminate inclusions, reduce trapped gas and provide laminar flow, make the molten metal becomes clean.

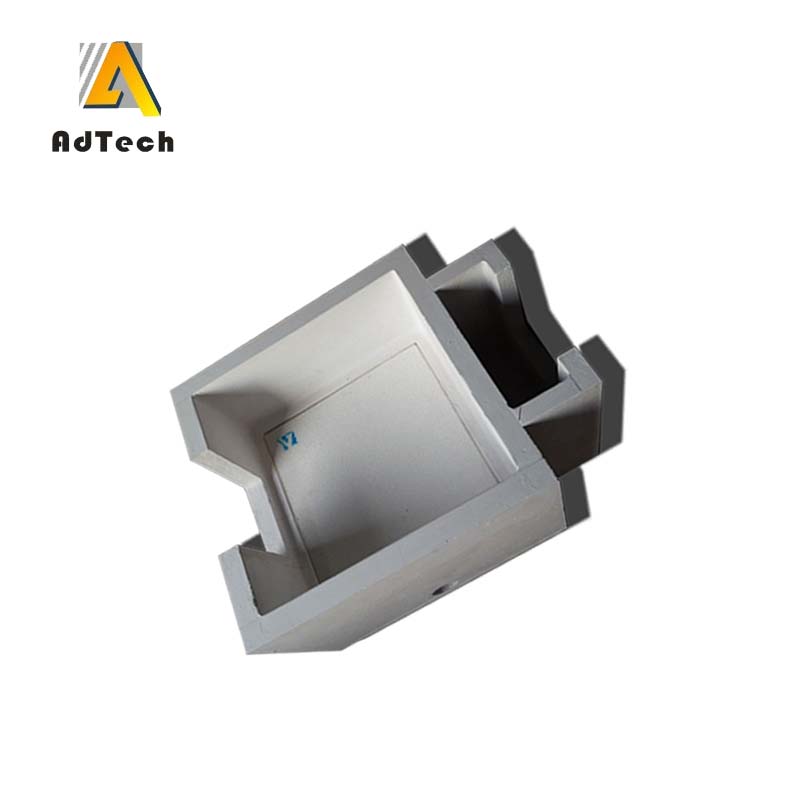

Hot sales super quality industrial silicon carbon ceramic foam filter for metal filtration

1.Alumina Ceramic foam Filter is developed as a new type molten metal filters to decrease casting flaw in recent years. Foamed ceramics have the characters of light weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, chemical corrosion resistance and high temperature stability in molten metal. With the distributing pores net structure, they are able to increase the surface areas, and absorb the sinter, the liquid metal becomes more pure, waster quality problems such as sand pore and air pore are much less and the cast quality becomes much better.

They are constructed of impregnated foam in a controlled open-pore structure to provide a superior filtration effect. We provide an efficient solution for the removal of oxides and non-metallic particles from a broad range of non-ferrous metals.

Inclusions nucleate porosity, create hot tears during solidification,cause surface defects that mar appearance, and often reduce mechanical properties. In many cases, filtration cuts rejects from such causes to virtually zero. Improvements in yield to near 100% and reduced reject rates to at or near 0% are common.