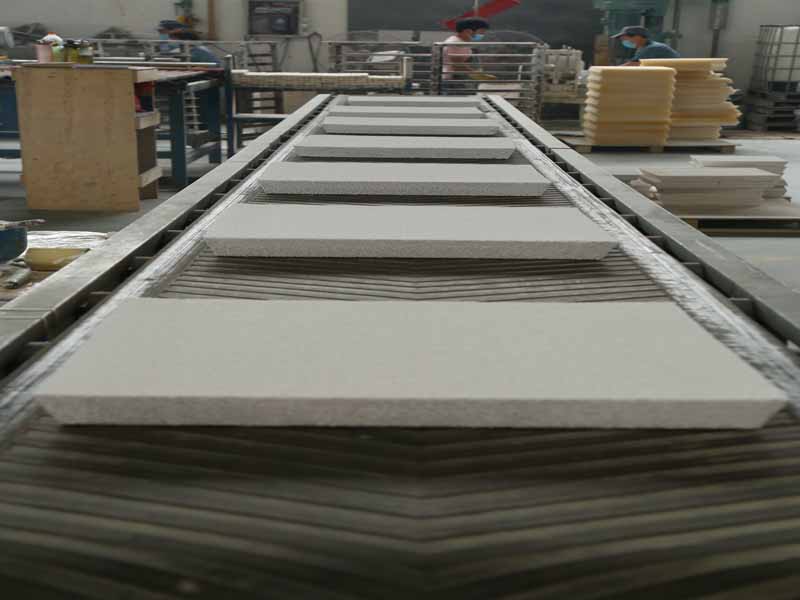

Ceramic Foam Filter Bulgarien Aluminium is used in aluminum rod melting and casting plants, with low cost and one-time use.

In addition, the filter has an amazing effect in filtering molten metal, especially aluminum, at low cost, thereby achieving amazing filtering efficiency and considerable flexibility.

Ceramic Foam Filter Bulgarien Aluminium can be conveniently used in various positions, including pouring trays, pouring troughs, transfer troughs, pouring ports and metal processing troughs. Ceramic Filter For Foundry should not be placed in turbulent flow, especially when close to the flow of molten metal, because turbulence will lead to the formation and entrainment of oxides. This is true for turbulence upstream and downstream of the filter.

In the process of melting, refining and forming of the metal, especially in the casting process of the molten metal, it is best to separate the inclusions from the molten metal.

Inclusions of impurities cause the presence of raw materials to form a melt, from slag, scum and oxides, the form of slag, the melting of the slag and oxide surface, and the small fragments of refractory materials used to form a chamber or a container in which the melt is formed The metal melts.

If these inclusions are not removed from the molten state of the metal, the quality of the finally solidified metal body (the final product of the casting operation) may deteriorate.

Generally speaking, in metal casting operations, metal melt is formed. Sometimes it is melted or refined in a furnace, where unmelted scrap and/or refined pure metal components are added.

Low-density solids are usually combined with partially or fully solidified oxides (referred to as slag and dross, respectively), blistering or floating to the surface of the melt.

These floating impurities can usually be scraped off the surface of the melt. However, higher density impurities tend to stay in the liquid melt as a certain degree of suspended matter and cannot be removed from the molten metal.

Ceramic Filter adopts the principle of adsorption to filter, which can effectively remove large inclusions in molten aluminum and effectively adsorb small inclusions of small size. No slag drop, effectively reducing pollution to molten aluminum. The ceramic foam filter plate is covered with an expandable gasket to make the filter box tighter. Preheating before use can prevent damage to the filter plate.