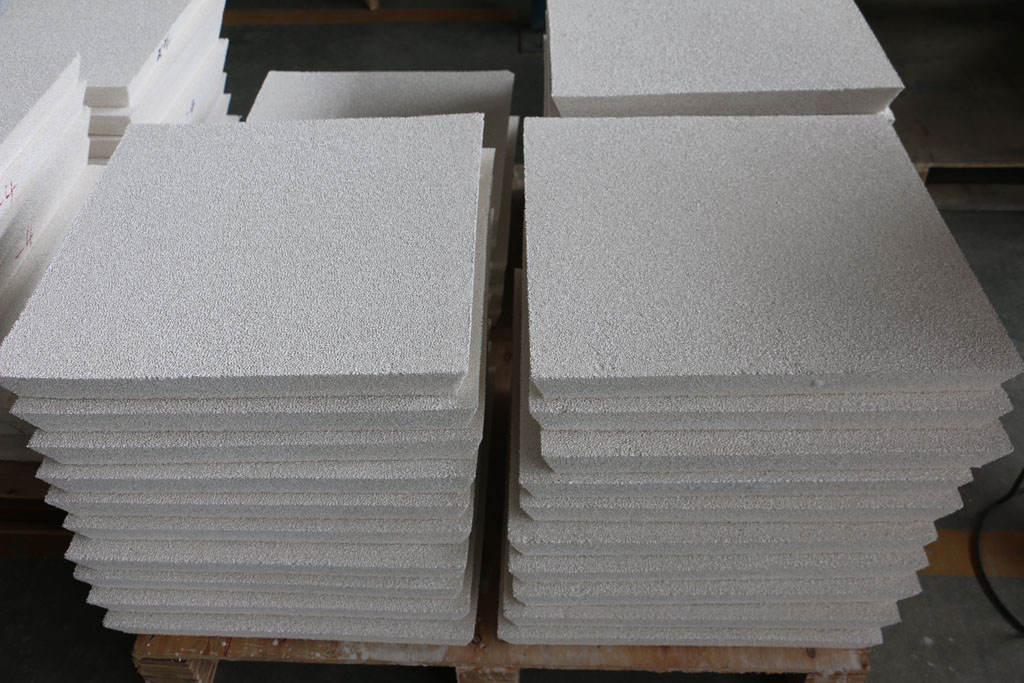

Ceramic Foam Filter Aluminum Columbia

As we all know, the Ceramic Foam Filter Aluminum Columbia plays a very important role in the aluminum liquid purification system.

Ceramic Foam Filter Aluminum Columbia can effectively remove the large inclusions in the aluminum liquid and effectively reduce the micro inclusion size of the micro inclusions, improving the surface quality and product performance.

Improve the role of the microstructure and increase the yield. As long as used in aviation, transportation and other aluminum alloy precision casting.

Ceramic Foam Filter Aluminum Columbia adopts three-dimensional mesh structure and organic carrier connected with air holes to invade special thixotropy special ZrO2 quality molten materials, adopting four-square correct center distance automatic extrusion technology, so that the slurry is evenly applied to the foam of the carrier. On the skeleton, it is baked and cured at a high temperature of 1680°C and has an expanded cotton body sealing edge.

The specifications of ceramic filter plates supplied by our company are: 7in, 9in, 12in, 15in, 17in, 20in, 23in, 26in or customized according to customer’s special.

It’s very important to choose and design Ceramic Foam Filter Aluminum Columbia model & filter seat correctly according to casting types and pouring weight. The general principle is that the whole gating system should be a system without pressure to ensure that the molten metal liquid filling mould smoothly. Ratio of the sectional area will be the main point.

Ceramic Foam Filter Aluminum Columbia Advantages

Increased Fluidity

Removal of inclusions makes the metal more fluid, resulting in easier mold fill, better cast structure, and better thin section castability.

Reduced Mold and Die Wear

Removal of inclusions and other nonmetallic debris from the melt reduces die soldering and mold-metal interaction, which degrades the mold surface and service life.

Longer Tool Life

Oxide as well as intermetallic inclusions create “hard spots” that damage tools in machining and finishing operations. Ceramic Foam Filter reduces tool wear and increases productivity.

While adding the filter print to the mould plate, the Ceramic Foam Filter has to be sized correctly to prevent filter breakage while casting. It is recommended to have a filter size of approx.. 1/5” for filters up to 3×2”, filters up to 4×4” need 1/3“ of filter seat while filters larger than 4×4” need approx. ?” filter seat. Filters up to 4×4” can be positioned vertically or horizontally inside of the mould/runner, larger filters should be positioned horizontally only. It is not recommended to position the filter at the bottom of the downsprue, as the risk of filter breakage is significantly increased. When ceramic foam filters are used, it is recommended to use a “pressure-free” casting system, to prevent re-oxidation of the molten Aluminum while casting.