Ceramic Foam Filter Aluminium Peru

Ceramic Foam Filter Aluminium Peru Application

For the filtration of molten aluminum and non ferrous alloy.

Alumina Ceramic Foam Filters mainly for filtration of aluminum and alloys in foundries and cast houses.

With the excellent resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas and provide laminar flow and then the filtered metal is significantly cleaner.Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

-Reduce scrap related to inclusions.

-Reduce costs related to inclusion defects.

-Increase productivity with higher extrusion or rolling speeds.

-Increase casting flexibility with easy alloy changes.

-No holding metal.

Ceramic Foam Filter Aluminium Peru For Foundry

Superior dimensional tolerances

Stable chemical composition

Highest filtration efficiency

Excellent strength

Resistant to corrosion attack by molten aluminum and alloys

Beveled edges and compressible gasket

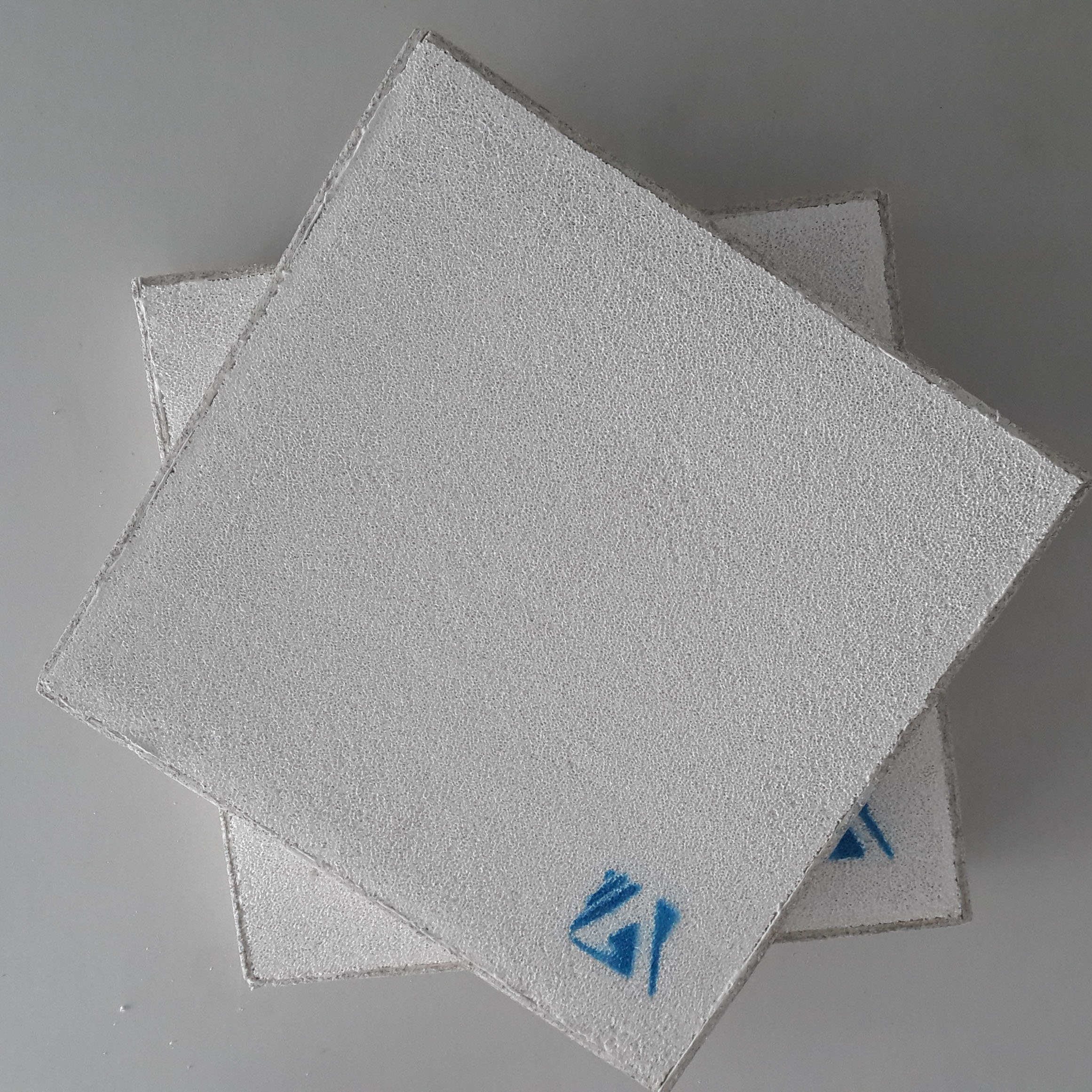

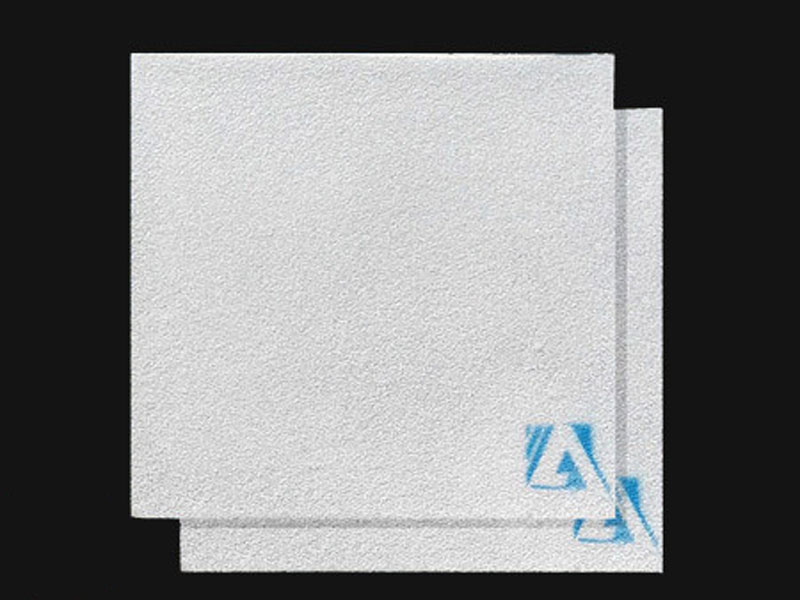

Ceramic Foam Filter Aluminium Peru SPECIFICATION

Color:White

Porosity:80-90%

Compression Strength (Room Temperature) :Above 0.8Mpa

Volume Density: 0.36-0.5g/cm3

Thermal Shock Resistance:1100°C to room temperature 6 times

Whole range of porosities from PPI 10 up to PPI 60 (PPI = pores per inch).

Available sizes:7x7x2″,9x9x2″,12x12x2″,15x15x2″,17x17x2″,20x20x2″,23x23x2″.

Aluminium is a metal found in the second row and Group 13 on the periodic table. It is the third most abundant element after oxygen and silicon to be found in the crust of the earth. Aluminium occurs naturally in compounds but never as pure metal. The process of extracting aluminum from its compounds is an elaborate and rather difficult. Aluminium is a useful and common metal that is known for being lightweight, its malleability, and corrosion resistant. Aluminium tends to be easier to recycle than to purify from ores. It is also safe enough when it comes in contact with skin and to be used around food.

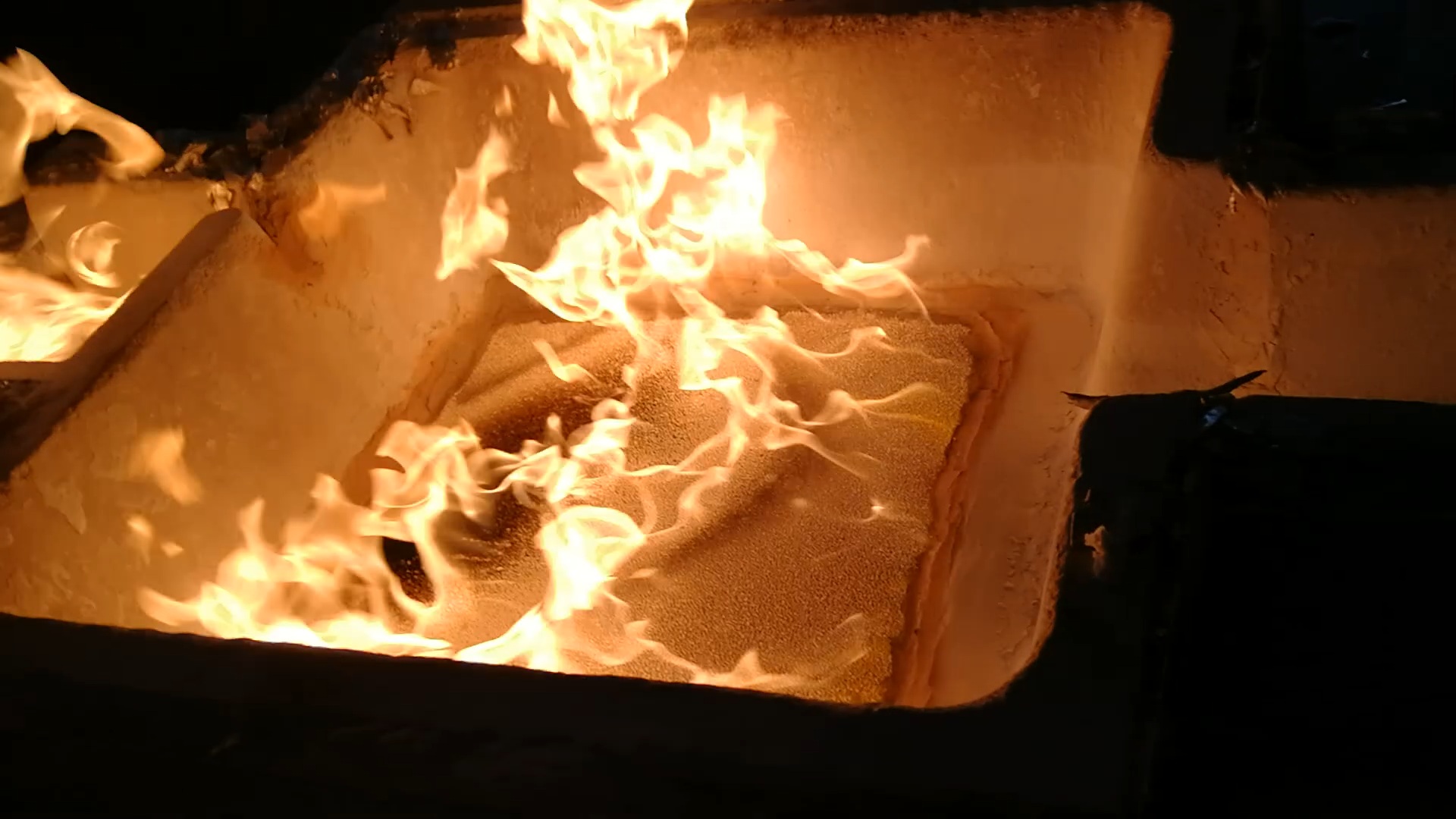

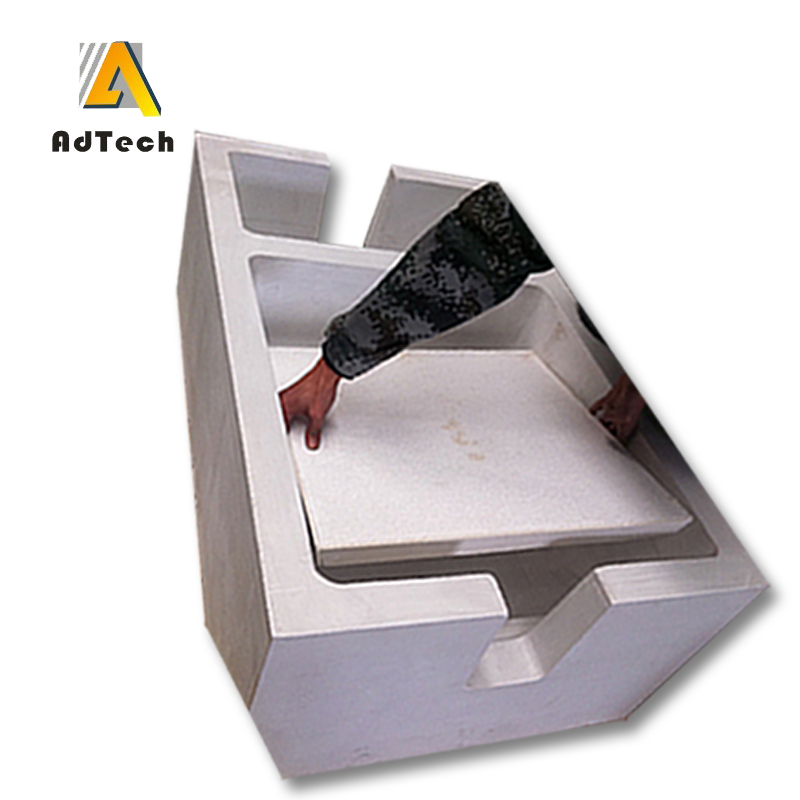

Ceramic Foam Filter Aluminium Peru Assembly

1. Clean the filter box.

2. Gently put the filter plate into the filter box and press the sealing gasket around the filter plate by hand to prevent the aluminum liquid from flowing.

3. Evenly preheat the filter box and filter plate to bring it close to the temperature of the aluminum liquid. Preheat to remove moisture and facilitate initial transient filtration. Preheating can be carried out using electrical or gas heating. Under normal circumstances, it takes about 15–30 minutes.

4. Pay attention to the change of aluminum hydraulic head during casting. The normal starting pressure head is 100-150mm. When the aluminum liquid begins to pass, the pressure head will drop below 75–100mm, and then the pressure head will slowly increase.

5. During the normal filtration process, avoid knocking and vibrating the filter plate. At the same time, the launder should be filled with aluminum water to avoid too much disturbance of the aluminum water.

6. After the filtration is finished, remove the filter plate in time and clean the filter box.