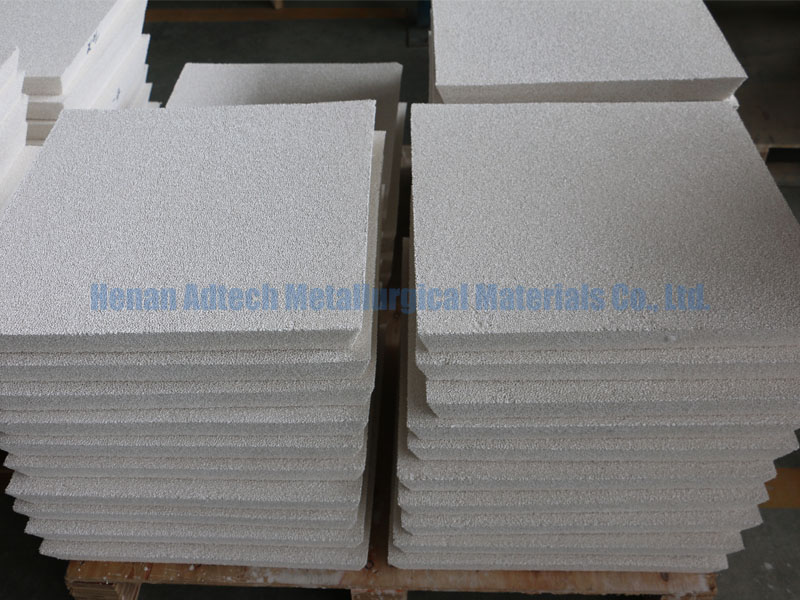

Ceramic Foam Filter

Alumina Ceramic Foam Filters are mainly applied for filtration of aluminum and aluminum alloys in foundries and cast houses .

With their excellent resistance to attack and corrosion from molten aluminum, they can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Alumina ceramic foam filter can be made by specific procedures and have peculiar bone-frame holes just like the shape of foa Called three-dimensional connected channel) and myriad eyelets which only been found in big times microscope. Compare to similar ones, our products have many advantages as below:

1.Stable chemical composition

2.Excellent strength

3.Resistant to high temperature

4.Calm down of the turbulent flow of metal nicely

5. big m2/m3

More information of Ceramic Foam Filter

Alumina Ceramic Foam Filter has the advantages of high porosity, low loss of thermal shock, high mechanical strength at normal

and high temperature, large specific surface, good chemical stability and excellent filtering functions of screen, filtering

residuum collection and adsorption especially for tiny impurity of 1~10μm.

The three-dimensional structure can improve the cast quality in large scale by changing the molten metal from turbulence flow to

lamellar flow, removing the gas and smoothing the casting. Ceramic foam filter is not only applied for molten metal filtering in

high temperature, but gas treatment in high temperature, carrier of catalyzer, solid heat exchange and advanced fil