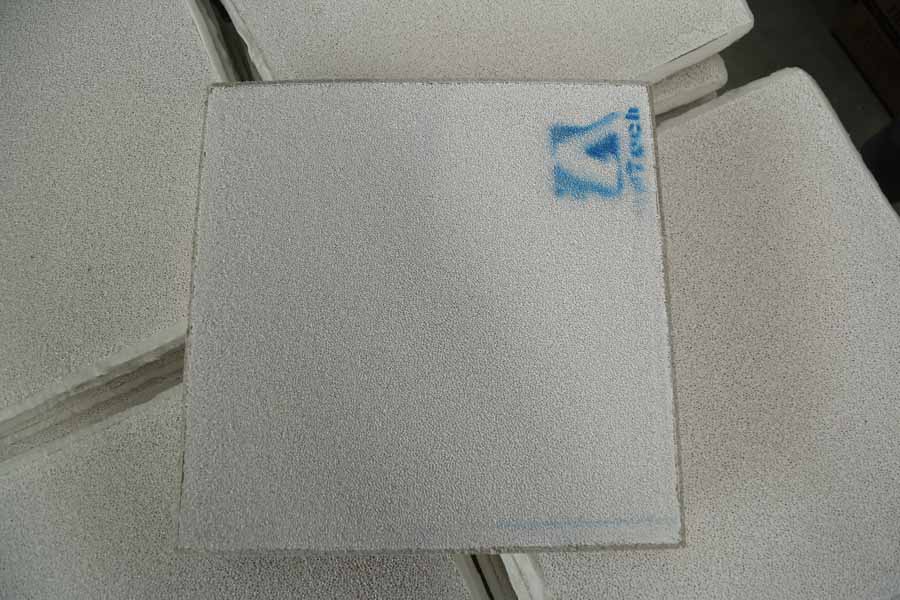

Ceramic Filter Suppliers In India Filtration has high porosity, low thermal shock loss, high mechanical strength at room temperature and high temperature, large specific surface area, good chemical stability, and excellent filtration and filtration functions. It collects and adsorbs tiny impurities from 1 to 10μm.

The three-dimensional structure can improve the quality of the casting in a wide range by changing the flow of the molten metal from the vortex to the thin layer, removing gas and smoothing the casting. Ceramic foam filter is not only suitable for high temperature filtration of molten metal, but also suitable for high temperature gas treatment, catalyst carrier, solid heat exchange and advanced filling in the chemical industry.

Ceramic filters for foundry are modern materials that are needed in many industrial fields. It is made of highly dispersed mineral powder, as well as liquid foam; it has a porous structure.

The unique properties of this material make it indispensable in many industries. Ceramic foam materials have low thermal conductivity and high heat resistance.

Ceramic filters for casting are used to separate molten metal and mechanical impurities. PFC is characterized by a so-called three-dimensional mutually open pore structure. This structure allows you to maximize the filtering process.

Because ceramic foam has many unique properties, ceramic foam filters are very much in demand in the metallurgical industry.

Ceramic Filter Suppliers In India Filtration has the following functions

1.Purify molten aluminum from metal and non-metal components.

2.Reduce the number of oxides during the formation of turbulence.

3.Increase the fluidity of the metal.

4. Eliminate inclusions and metal defects.

5. Improve mechanical properties and improve the quality of castings.

6.Reduce the formation of waste and eliminate extra work.

All ceramic foam filters are characterized by a grid matrix. Spherical holes of the same size and volume are connected to each other, forming “windows” through their walls.

Because of its structure has a rather tortuous path, the pores can pass through the metal and retain slag and other types of contaminants.

In the end, this ppa-based filter with a specific structure has shown excellent efficiency when filtering metals in the context of filters with different structures used in the foundry industry.

Among various types of metal oxide ceramics, alumina has the best high temperature stability.

Most suitable for ceramic coatings and high temperature refractory products.

The thermal conductivity of alumina is the lowest among ordinary ceramic materials, and its thermal expansion coefficient is relatively close to that of metal materials.

It is impossible for modern casting to use this type of filtration.

Malaysian customers visited the AdTech factory and had in-depth exchanges with our technical staff. Visited the production line of degassing device, filter box, Molten Aluminum Launder, cast ceramic filter, and hot top product.

Press Metal has an in-depth understanding of Ceramic Filter Suppliers AdTech products and asked about the production process of the products. Malaysian customers speak highly of AdTech’s product quality and equipment workshops. They had an in-depth discussion on the heating system and tilting device. Our technicians answered the questions in detail and solved the customer’s problem.

Press Metal is a Malaysian aluminum company with operations all over the world. Stamped metal has always been our strategic main customer. We have established a solid cooperative relationship with the company on ceramic filters, refining agents, washing equipment, degassing devices, filter boxes, hot top accessories and other casting products.

This visit gave Press Metal a deeper understanding of AdTech and laid a solid foundation for closer business cooperation in the future. The company has strong technical force and management system. We will continue to provide the highest quality products and the most attentive service.