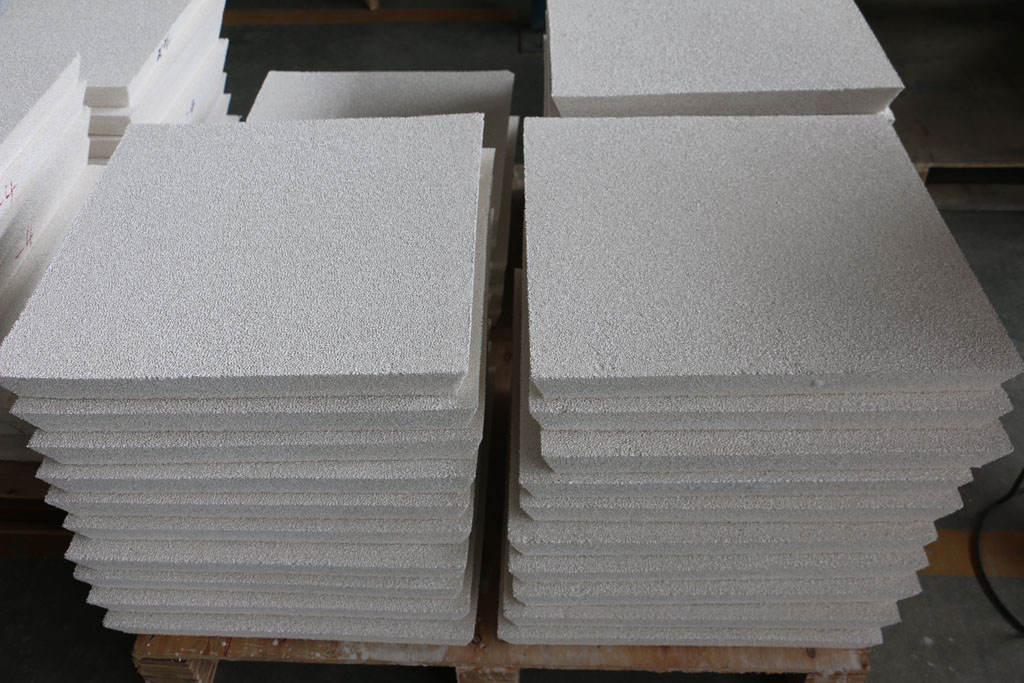

Ceramic Filter Suppliers Argentina Aluminium

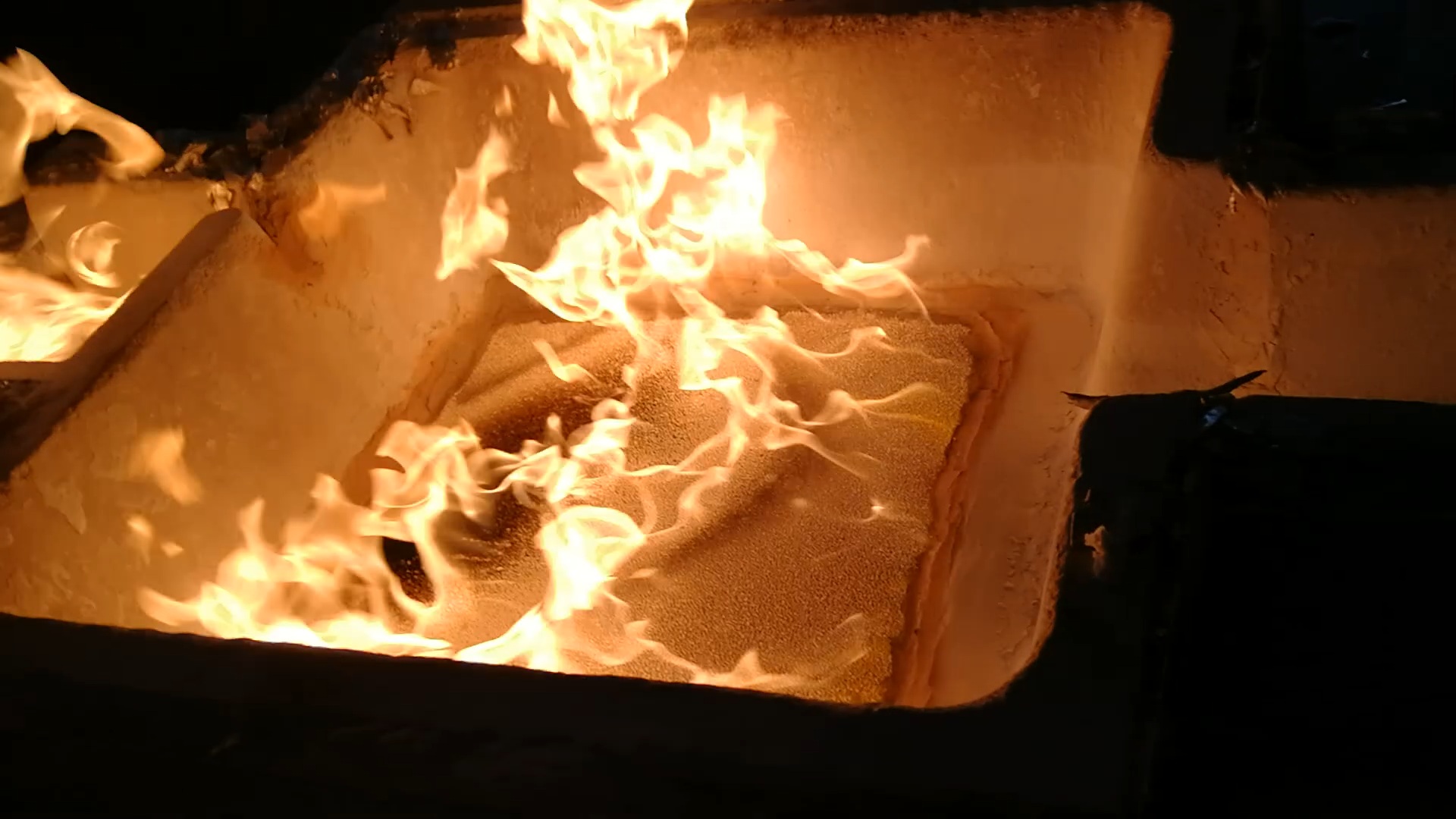

Ceramic Filter Suppliers Argentina Aluminium is developed as a new type molten metal filter to decrease casting flaw in recent years. Foamed ceramics have the characters of light weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, chemical corrosion resistance and high temperature stability in molten metal. With the distributing pores net structure, they are able to increase the surface areas, and absorb the sinter, the liquid metal becomes more pure, waster quality problems such as sand pore and air pore are much less. and the cast quality becomes much better.

Ceramic Filter Suppliers Argentina Aluminium can effectively remove and absorb large or small impurities in molten aluminum,improve the surface quality, product performance and microstructure effectiveness. Mainly used in the domestic, construction, electricity, condensing tubes, cable and other aluminum alloy precision casting.

1. Aluminum alloy bar choose: 10-30ppi

2. Long-term casting choose: 30-50ppi

3. High quality aluminum profile or plate choose :40 or 50ppi

4. Double zero wave continuous casting and rolling choose: >50ppi

5. Other specifications can be customized as your requirments

Ceramic Filter Suppliers Argentina Aluminium manufacturered in China

1>. 3D reticulate structure

2>. High mechanical strength, no-dregs off when flapping

3>. High porosity

4>. Large surface areas, strong absorptivity of impurities

5>. Excellent thermal shock resistance

6>. Rapid improvement in filed

Ceramic Filter Suppliers Argentina Aluminium Function & Advantages:

AdTech Ceramic Foam Filters offer the best way to eliminate non-metallic inclusions, foreign materials that are a major source of quality problems in casting. and help you meet ever increasing demands for quality.

Get rid of the impurity, refractory scrap, solid refractory alloy, sinter, in the molten metal liquid when casting the products, get rid of turbulent flow, reduce the air cavity of castings, raise the quality of cast. So our ceramic foam filters (foamed ceramics) are widely used in the aluminum foundry industry, for preventing defects caused by oxides, dross, gas, slag and other impurities.

Eliminates turbulence in the metal stream, Smoothes out metal flow, avoiding sprays, splatter and backset. Improve fluidity, castability, machinability, yield and cost-effective.

Remove a much greater fraction of fine particulate, Reduce rejects and rework

Low-pressure loss.

Provides consistent flow rate and capacity.

Various sizes, shapes and pore sizes are available.

How Does Efficient Filtration Improve the Whole Process

AdTech Ceramic Foam Filters offer benefits that improve molten metal handling, casting, machining, and the finished product itself.