Ceramic Filter Suppliers Aluminum Columbia

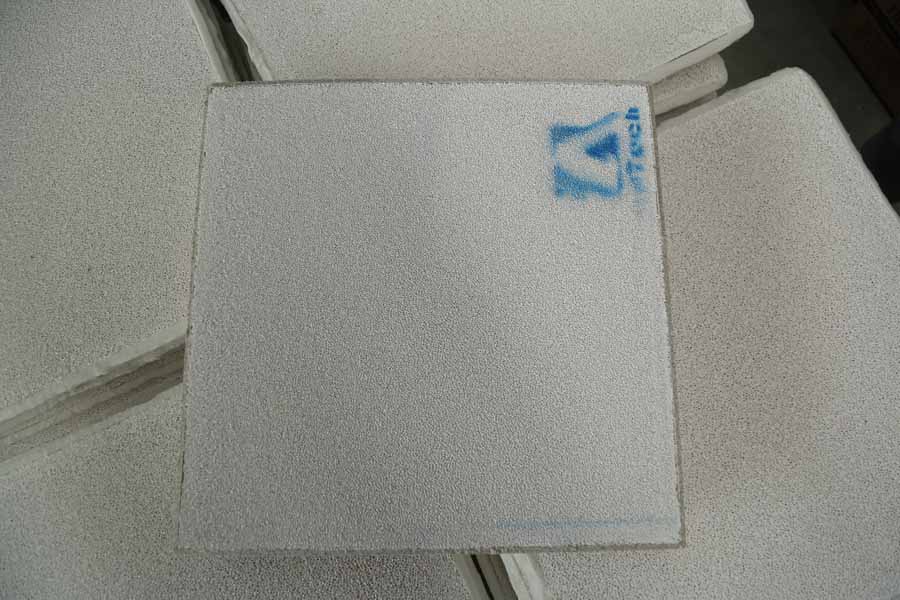

Ceramic Filter Suppliers Aluminum Columbia mainly for filtration of aluminum and alloys in foundries and cast houses.

With the excellent resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas and provide laminar flow and then the filtered metal is significantly cleaner.

Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Ceramic Filter Suppliers Aluminum Columbia Product Usage

It can effectively remove large inclusions in aluminum liquid and adsorb micron-sized fine inclusion particles, which can improve surface quality, improve product performance, improve microstructure and improve yield. It is widely used in the production fields of aluminum profiles, aluminum foils, and aluminum alloys.

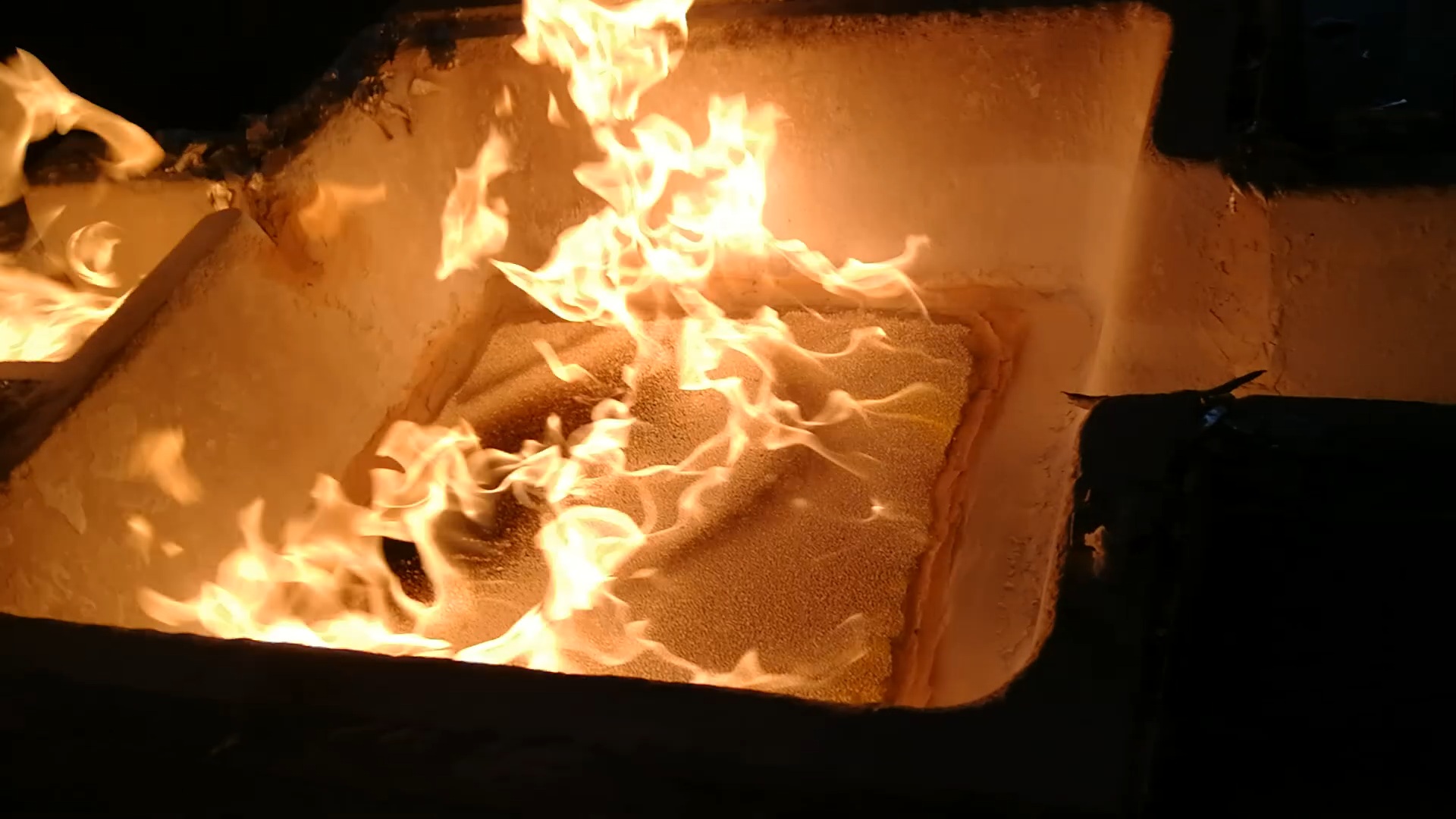

Ceramic Filter Suppliers Aluminum Columbia Thermal Shock Resistance

Thermal shock resistance refers to the resistance of alumina filter plates to damage caused by rapid temperature changes. During the use of the alumina filter plate, we require the user to start the filtration when the filter plate is gradually preheated to the temperature of the filtered aluminum melt before use, but some users do not follow this well when using it. It is stipulated that after the filter plate is placed, the melt is filtered without preheating, so that the filter plate is required to have a certain thermal shock resistance. The better the thermal shock resistance, the more durable the filter plate and the better the quality.

Ceramic Filter Suppliers Aluminum Columbia Filtration

-Reduce scrap related to inclusions.

-Reduce costs related to inclusion defects.

-Increase productivity with higher extrusion or rolling speeds.

-Increase casting flexibility with easy alloy changes.

-No holding metal.

Application for Ceramic Filter Suppliers Aluminum Columbia

Alumina Ceramic Filtration

is produced basing on carrier with solid reticular structure and combined organic foam pores.

The producing procedure is as below, put carrier into the thixotropic alumina slurry, adopt square to center correcting automatic extrusion process, so that slurry evenly deposits in foam skeleton of carrier, after drying solidification, then carrier will turn into final product by roasting formed under 1180 ℃ high temperature.

Alumina Ceramic Filtration

is installed in the filter bowl for filtrating impurity in molten aluminum alloy, which helps to meet the requirement of production in high value-added, high-tech performance aluminum alloy precision casting, such as computer hard drive, PS baseboard for printing, canning materials, fan blades for turbojet engine, etc.

Ceramic Filter Suppliers Aluminum Columbia Features

*Superior dimensional tolerances

*Stable chemical composition

*Highest filtration efficiency

*Excellent strength

*Resistant to corrosion attack by molten aluminum and alloys

*Beveled edges and compressible gasket