Ceramic Filter Supplier

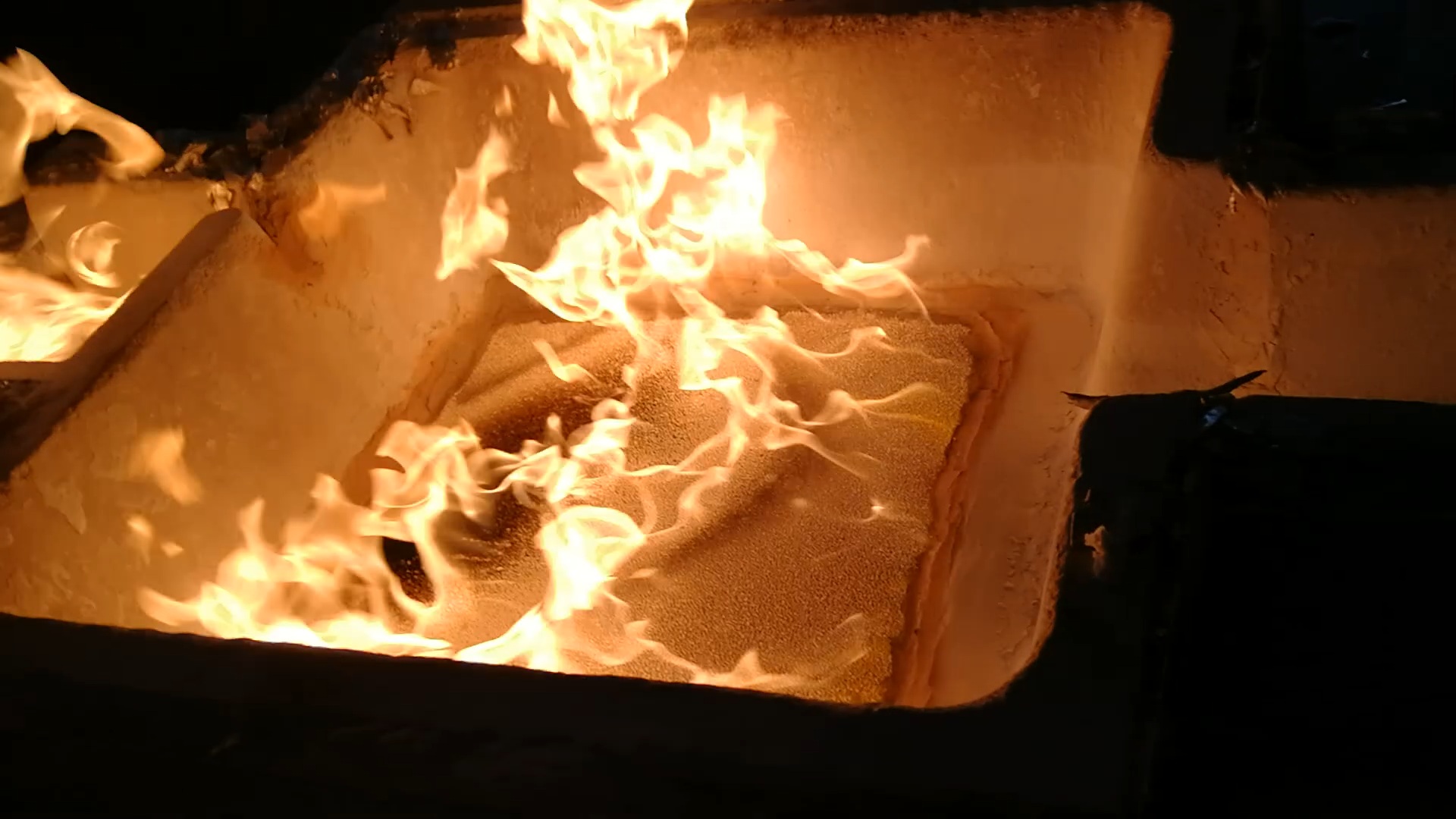

Ceramic Filter application temperature – up to 1700 ° C (with short-term use, higher temperatures are also possible). To ensure optimal filter efficiency, they must be preheated.

Three types of ceramic foam filters are offered, which are made on the basis of:

aluminum oxide (for filtering aluminum at temperatures up to 1150 ° C);

Ceramic Filter Supplier: sales@adtechamm.com

zirconium dioxide (for filtering steel, as well as alloys based on nickel and cobalt, at temperatures up to 1700 ° C). Special application – casting of magnesium;

silicon carbide (for filtering ductile and ductile iron, as well as non-ferrous metals at temperatures up to 1420 ° C).

For particularly critical products, duplex filters can be used, the distinguishing feature of which is the combination of two types of porosity in one filter of a standard size: porosity PPI 10/30 with sizes from D 100 * 25 mm.

It is possible to use filters at various points of the foundry system: horizontally or vertically along the way, at the base of the gate or profit.

In addition, when casting, due to the three-dimensional structure of the filter, the metal flow is effectively stabilized, the form is filled more smoothly and evenly. Due to this, the deoxidation of the metal in the mold, as well as the erosion of the moldable mixture, is significantly reduced.