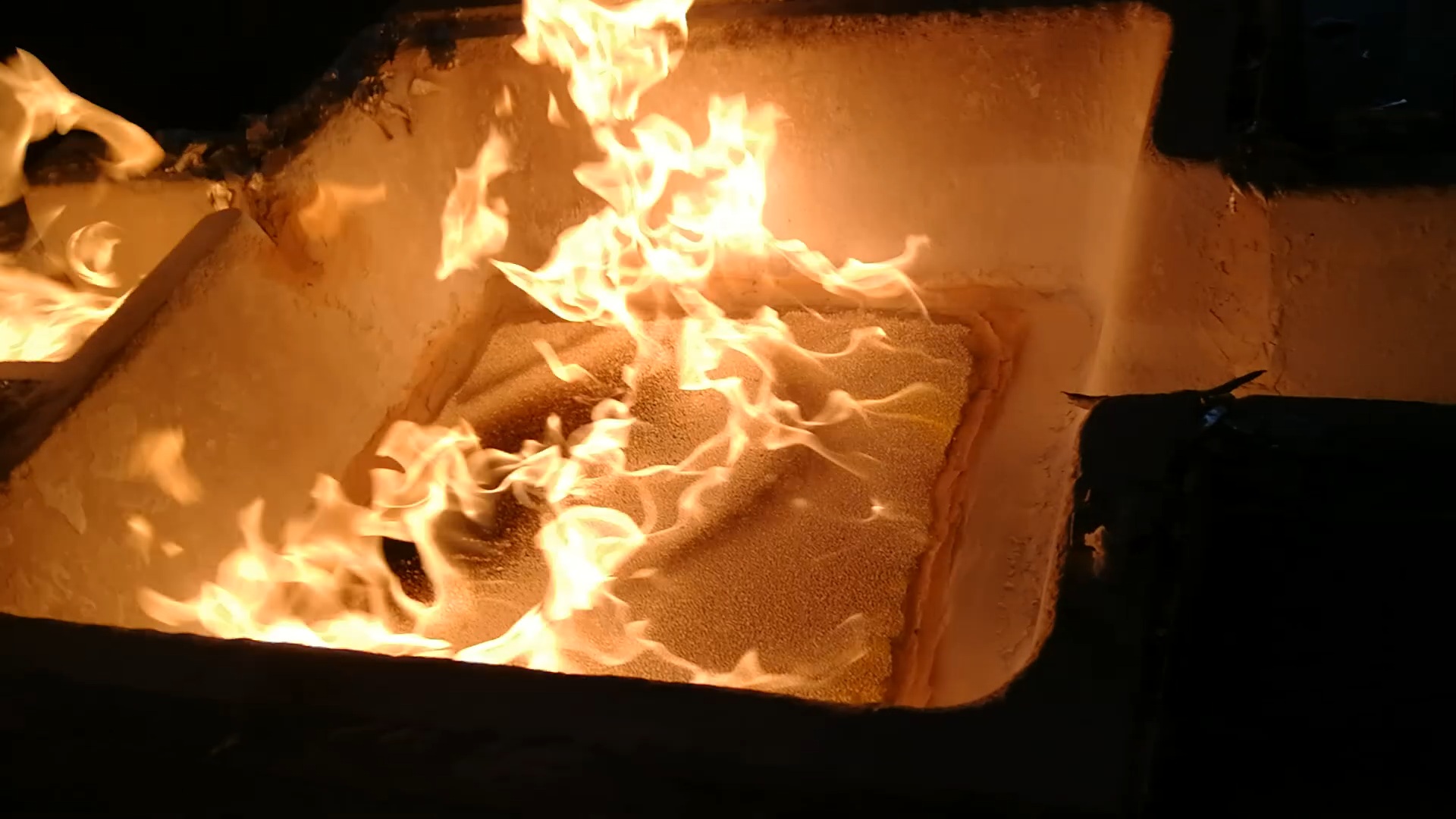

Ceramic Filter Showa Aluminum Indonesia is installed in the CFF casthouse to filter the impurities in the molten aluminum alloy.

Aluminum alloy is easily inhaled and oxidized during the casting process. Therefore, there are gases and various non-metallic inclusions in the melt to varying degrees, causing defects such as loose ingots, pores, and inclusions.

Significantly reduce the mechanical properties, processing properties, fatigue resistance, erosion resistance, and anodic oxidation properties of aluminum, and even lead to product scrapping. Therefore, Ceramic Filter Showa Aluminum Indonesia is very important in the aluminum alloy casting process.

Aluminium casting Ceramic foam filter Classification

In accordance with its material, ceramic foam filter can be divided into Ceramic Foam Filter as a iron filter for molten iron, Alumina Ceramic Foam Filter as a molten aluminum filter for molten aluminum casting, and Zirconia Ceramic Foam Filter as a steel filter for molten steel casting industry.

Aluminium casting Ceramic foam filter Installation

The filtration efficiency of Ceramic foam Filter of the aluminum plant is closely related to its proper installation and use. At the same time, it is not possible to ignore the conventional and necessary measures taken to reduce the occurrence of inclusions in the process operations such as smelting, furnace treatment, and casting, because the filtration process is employed. It is also necessary to prevent re-contamination of the cleaned aluminum liquid after filtration.

If the export of bauxite is restricted, then aluminum casting must be processed locally in Indonesia.

ADTECH keeps focusing on the manufacture of the metallurgical material.

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

1.Ceramic Foam Filter

2.Degassing Unit

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

SALES@ADTECHAMM.COM

On October 19, 2021, Indonesian President Joko Widodo stated that the country plans to stop exporting all important raw materials in order to attract investment in land-based resource processing and job creation.

As the world’s largest island country, Indonesia has banned the export of a variety of raw ores including nickel, tin and copper in order to revitalize downstream industries including electric vehicle battery manufacturing and the aluminum industry.

The President said in Bebatu Village on Borneo Island that at present, the Indonesian government is conducting feasibility studies on the downstream of other commodities, focusing on the long-term vision of not just selling raw materials.

The president added: “The new policy is expected to be introduced next year. Don’t be surprised. We have had nickel before (export ban). Next year, we may stop exporting bauxite, and next year we may stop other things.”

However, according to current regulations, Indonesia will ban the export of bauxite in 2023.

“We really want to stop exporting raw materials because it has no added value and will not create jobs. The policy will affect all commodities,” he said.