Ceramic Filter Pt Indonesia Aluminum is provided by a Chinese manufacturer to sell ceramic foam filters to a local aluminum factory.

The purpose of Asia Foundry Filter purification is to remove alumina and hydrogen slag in aluminum smelters to improve the process and mechanical properties of aluminum materials or products.

The filtration purification method is a method of filtering impurities, gases, and certain harmful elements in aluminum alloy through Ceramic Filter Pt Indonesia Aluminum in the process of casting or salt casting.

The principle of ceramic foam filters is adsorption filtration and mechanical filtration.

The mechanical properties of aluminum alloy filter castings are very good, which can improve the strength, toughness, and elongation.

After the molten aluminum is filtered, the quality of ingots and castings has also been significantly improved.

There are many materials for filtering lead, such as glass cloth, refractory fiber mesh, magnesium fluoride, calcium fluoride, and so on.

For Asian casting filter agents, please contact the Chinese manufacturer sales@adtechamm.com

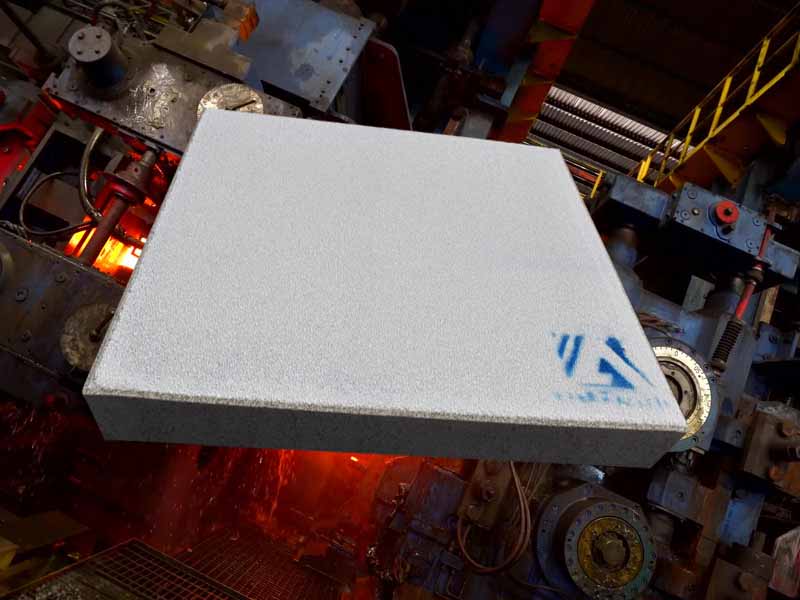

With the extensive and in-depth application of aluminum alloys in aerospace, missile, automotive, and other industries, our company’s quality requirements for aluminum alloys are becoming more and more stringent.

In addition to chemical composition and qualified mechanical properties, internal quality and surface quality are also required.

Due to excessive gas and non-metallic impurities, traditional smelting and casting processes cannot meet these requirements.

In order to reduce the influence of gas and non-metal impurities, people have put forward strict requirements on the raw materials and smelting process of ironmaking on the one hand, and on the other hand, they are committed to the research and application of advanced smelting purification. Technology.

The refining of molten aluminum has become a very important production link for aluminum alloys. Advanced refining technology is very important to ensure the metallurgical quality of aluminum alloy and improve the final use performance of the product.