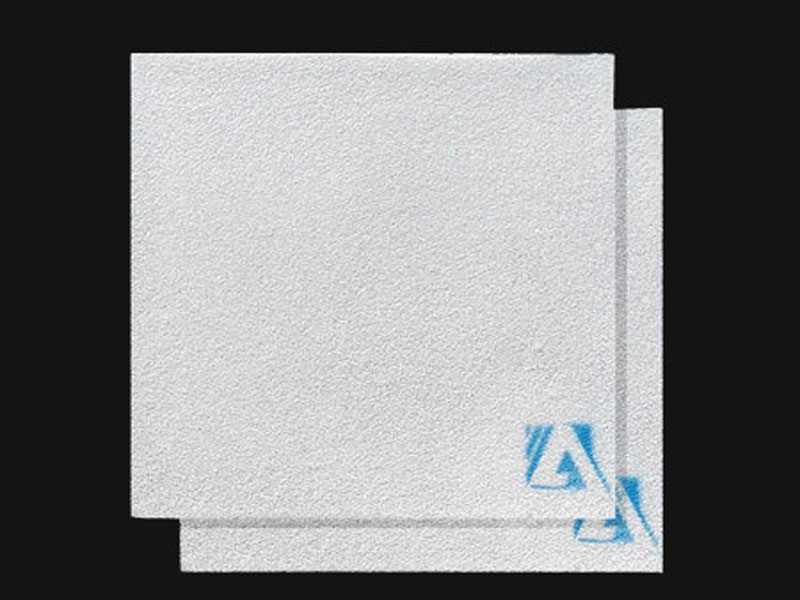

Ceramic Filter Malaysia also known as the foam ceramic filter plate, is composed of three types: alumina ceramic filter plate, silicon carbide ceramic filter plate and zirconia ceramic filter plate.

The three-dimensional network of traits has a uniform skeletal structure with pink or white lumps.

Ceramic Filter Features

It can effectively remove large inclusions in aluminum liquid and adsorb micron-sized fine inclusion particles, which can improve surface quality, improve product performance, improve microstructure and improve yield, in aluminum profiles, aluminum foils, aluminum alloys. It is widely used in production fields.

Ceramic Filter is made of non-stick aluminum material, which has the characteristics of non-stick aluminum, and the product is white or milky white.

Ceramic Filter is suitable for the production of high quality and high requirements aluminum and aluminum alloy purification process, through physical adsorption and chemistry.

Ceramic Filter can effectively remove various oxidation inclusions generated during the aluminum smelting process, thereby reducing casting defects, improving casting quality, and providing high quality materials for further deep processing.

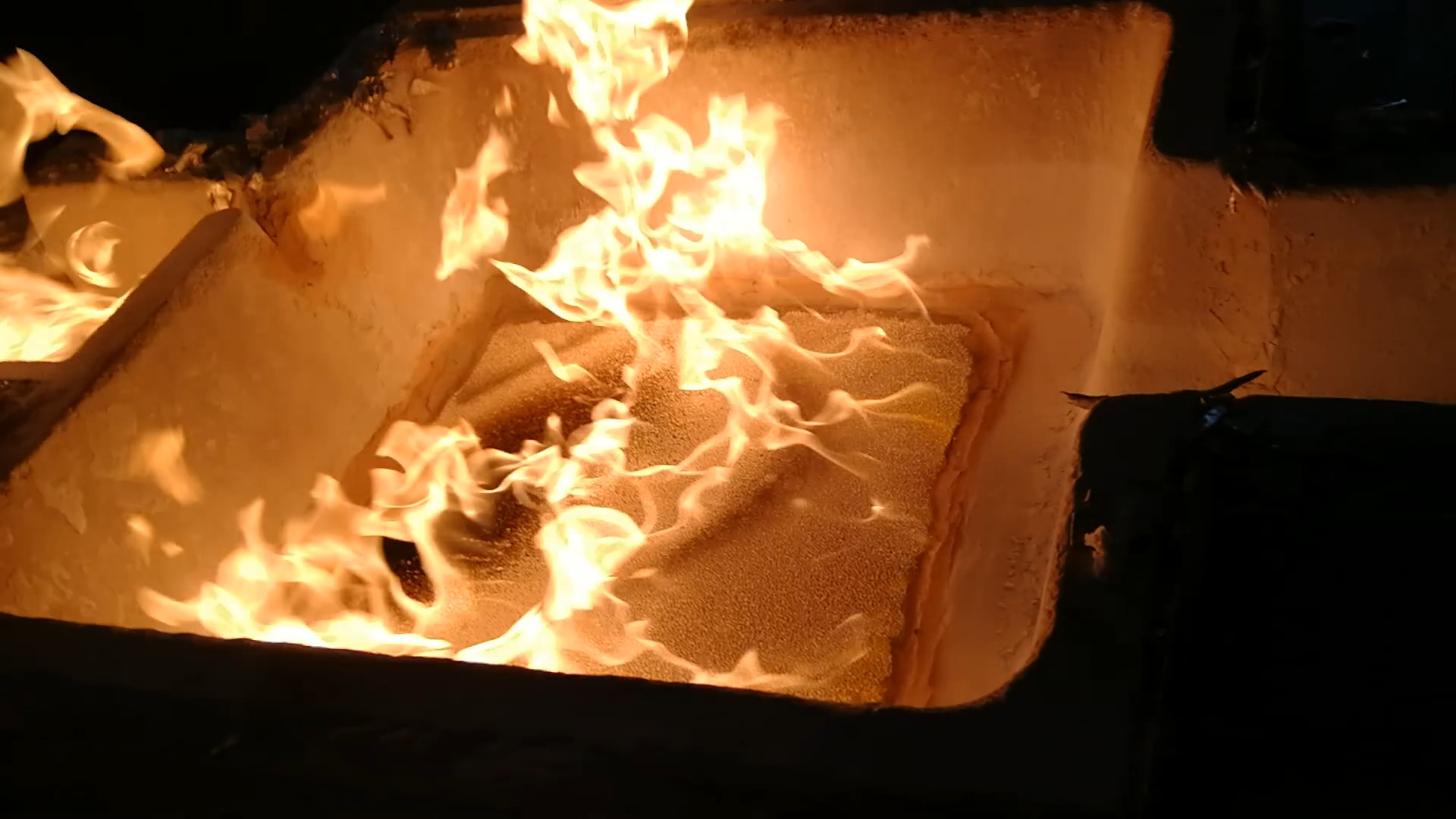

Ceramic Filtershould be preheated before use, and the filter plate should be completely sealed in the aluminum water filter box to ensure that all the aluminum water passes through the filter plate, and the total amount of filtration should not exceed the specified limit, if the amount of slag in the aluminum water If it is too high, it should be adjusted by multiple pieces of filtration or by reducing the throughput.

Ceramic Filter Malaysia Aluminium Usage Method

1. Clean the filter box.

2. Gently put the filter plate into the filter box and press the sealing gasket around the filter plate by hand to prevent the aluminum liquid from flowing.

3. Evenly preheat the filter box and filter plate to bring it close to the temperature of the aluminum liquid. Preheat to remove moisture and facilitate initial transient filtration. Preheating can be carried out using electrical or gas heating. Under normal circumstances, it takes about 15–30 minutes.

4. Pay attention to the change of aluminum hydraulic head during casting. The normal starting pressure head is 100-150mm. When the aluminum liquid begins to pass, the pressure head will drop below 75–100mm, and then the pressure head will slowly increase.

5. During normal filtration, avoid knocking and vibrating the filter plate. At the same time, the flow cell should be filled with aluminum water to avoid too much disturbance of aluminum water.

6. After the filtration is finished, remove the filter plate in time and clean the filter box.

Ceramic Filter Suppliers Adtech