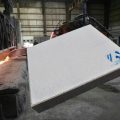

Ceramic Filter Loker Inalum has a porous ceramic body with high porosity and a three-dimensional square structure, which is shaped like tempered foam or porcelain sponge, and is used to filter non-metallic impurities in molten aluminum.

China began to study foam ceramic products in the early 1980s.

In the past 20 years, more than a dozen scientific research and manufacturing research institutions have reported on the research of foam ceramic products.

There is still a certain gap between my country’s foam ceramic products and foreign countries in terms of overall technical level.

Because of its high porosity, large specific surface area, thermal shock resistance, high temperature resistance, chemical corrosion resistance, good mechanical strength and filter adsorption performance.

It can be widely used in heat exchange materials, gas materials, automobile exhaust equipment, metallurgical industry refining, molten metals, heat recovery, light industrial coating industry, industrial waste treatment, heat and sound insulation materials, as chemical catalyst operating agents, electrolytic membranes and Discrete component separation, etc.

The Ceramic Filter Loker Inalum takes the three-dimensional structure and the organic foam sponge connected with the pores as the carrier, infiltrates the thixotropic special ceramic slurry, and uses a special roll extrusion process to evenly coat the ceramic slurry on the filter material. Carrier bone.

Then, it is dried and cured, and then fired at a high temperature.

Ceramic foam filter Ceramic filter Aluminum alloy ceramic filter Since the first research in 1978, foam ceramic filtration technology has developed rapidly.

The porous ceramic foam filter uses polyurethane foam as the carrier, immersed it in a layer composed of ceramic powder, binder, sintering aid, suspending agent, etc., and then extruded the excess layer to coat the ceramic layer evenly on the carrier .

The bone becomes a green body, and the green body is dried and fired at a high temperature.

Features of ceramic foam filter

Ceramic Foundry Filter can effectively remove large inclusions in molten aluminum, adsorb micron-level inclusion particles, improve surface quality, improve product performance, improve microstructure, and improve effect.

It is widely used in the production of aluminum profile, aluminum foil and aluminum foil.

Alumina shaft ceramic filter factory point

Structural characterization of specific reactions in terms of pore size, pore distribution, pore shape and porosity;

The pore structure of the membrane is closely related to the filtration transmission performance.

Pore size and pore size distribution are the most important parameters of the membrane structure, which directly affect the transfer characteristics of the fluid in the membrane and determine the separation and filtration performance of the membrane surface.