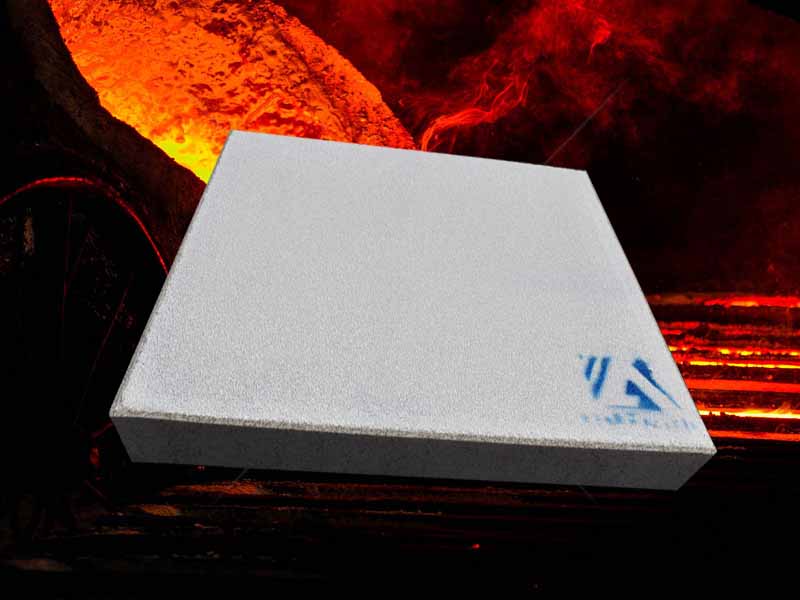

Ceramic Filter Indonesia Nickel can effectively remove large inclusions in molten aluminum, adsorb micro-scale inclusion particles, improve surface quality, improve product performance, improve microstructure, and improve results.

It is widely used in the production of aluminum profile, aluminum foil and aluminum foil.

The production process of Ceramic Foam Filter Aluminium

The ceramic foam filter takes the three-dimensional structure and the organic foam sponge connected with the pores as the carrier, infiltrates the special ceramic slurry with thixotropy, and uses a special rolling extrusion process to evenly coat the ceramic slurry on the carrier bone.

Ceramic Foam Filter Molten Aluminium Filtration

10 Ppi, 20 Ppi, 30 Ppi, 40 Ppi, 50 Ppi 60 Ppi ceramic foam filter

Filter 10 PPI Foundry Foam Filter means that there are 10 honeycomb holes in a square inch of filter sponge.

The 30PPI sponge filter has 30 small holes in one square inch. The larger the value, the smaller the hole.

Generally, 15-20 PPI means large pores, 25-30 PPI means medium pores, and more than 35 PPI means small pores.

10-50Ppi alumina ceramic foam filter, the vacuum degree is above 97%, and the open cell rate is 99%. Has good air permeability and high mechanical strength. Therefore, it has the characteristics of small flow resistance and high filtration efficiency.

Ceramic Filter Indonesia Nickel

Porosity is the percentage of the total cavity volume of the filter plate product to the total volume of the filter plate product.

The porosity determines the filtration capacity per unit volume of the ceramic foam filter plate.

The greater the porosity, the greater the filtration flow rate of the filter plate, and the stronger the filtration capacity.

Pore size uniformity of ceramic foam filter

Pore uniformity is used to describe the difference between the actual number of holes per 25.4 mm length of the filter plate product and the theoretically required number of holes.

The smaller the gap, the better the product quality, and the larger the gap, it will cause the impurity retention capacity of the filter plate product to decrease or the melt filtration speed to slow down, which cannot meet individual requirements. User production.

The uniformity of the pores mainly depends on the foam used to produce Filter Foundry. The uniformity of the foam holes is good, and the uniformity of the filter plate holes is good, so the choice of foam is very important.

Basa Jawa Basa Indonesia

Filter Keramik Indonesia Nikel kanthi efektif bisa mbusak inklusi gedhe ing aluminium cair, nyerap partikel inklusi skala mikro, ningkatake kualitas permukaan, ningkatake kinerja produk, ningkatake struktur mikro, lan ningkatake asil.

Iki digunakake digunakake ing produksi profil aluminium, aluminium foil lan aluminium foil.

Proses produksi Keramik Foam Filter Aluminium

Filter busa keramik njupuk struktur telung dimensi lan spons busa organik sing disambungake karo pori-pori minangka operator, nyusup slurry keramik khusus kanthi thixotropy, lan nggunakake proses ekstrusi rolling khusus kanggo nutupi slurry keramik ing balung operator.

Keramik Busa Filter Molten Aluminium Filtrasi

10 Ppi, 20 Ppi, 30 Ppi, 40 Ppi, 50 Ppi 60 Ppi filter busa keramik

Filter 10 PPI Foundry Foam Filter tegese ana 10 bolongan honeycomb ing inch kothak saka karang Filter.

Filter spons 30PPI duweni 30 bolongan cilik ing siji inci persegi. Sing luwih gedhe regane, luwih cilik bolongane.

Umume, 15-20 PPI tegese pori gedhe, 25-30 PPI tegese pori medium, lan luwih saka 35 PPI tegese pori cilik.

Filter busa keramik alumina 10-50Ppi, tingkat vakum ing ndhuwur 97%, lan tingkat sel mbukak 99%. Nduwe permeabilitas udara sing apik lan kekuatan mekanik sing dhuwur. Mulane, nduweni karakteristik resistensi aliran cilik lan efisiensi filtrasi sing dhuwur.

Filter Keramik Indonesia Nikel

Porositas punika persentasi saka total volume rongga saka produk piring Filter kanggo volume total produk piring Filter.

Porositas nemtokake kapasitas filtrasi saben volume unit piring filter busa keramik.

Sing luwih gedhe porositas, sing luwih gedhe tingkat aliran filtrasi saka piring Filter, lan kuwat kapasitas filtrasi.

Keseragaman ukuran pori saringan busa keramik

Keseragaman pori digunakake kanggo njlèntrèhaké prabédan antarane jumlah bolongan nyata saben 25,4 mm dawa produk piring Filter lan jumlah bolongan sing dibutuhake sacara teoritis.

Sing luwih cilik longkangan, sing luwih apik kualitas produk, lan luwih gedhe longkangan, iku bakal nimbulaké kapasitas penylametan impurity saka produk piring Filter suda utawa kacepetan filtrasi nyawiji kanggo alon mudhun, kang ora bisa ketemu syarat individu. Produksi pangguna.

Keseragaman pori-pori utamane gumantung saka busa sing digunakake kanggo ngasilake piring panyaring. The uniformity saka bolongan umpluk apik, lan uniformity saka bolongan plate Filter apik, supaya pilihan saka umpluk penting banget.