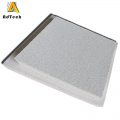

Ceramic Filter Indonesia Aluminium removes the oxidation inclusions in the aluminum alloy smelting process, and the technology of ceramic foam filtration outside the furnace has long become an important method for the purification of molten aluminum.

When the molten metal passes through the ceramic foam filter with complex structure, the filter medium filters out the inclusions larger than the pore size of the filter surface through mechanical separation, and makes them precipitate on the surface of the filter.

When filtering molten metal, since the temperature of the molten aluminum filter is significantly lower than the pouring temperature of the molten metal, the initial molten metal in contact with the filter must transfer heat to Foam Ceramic Filter.

As the filter absorbs heat from the metal, the temperature of the exposed portion of the molten metal decreases, causing the metal to solidify.

When the metal hardens in the filter, the solid metal may completely or at least partially block the filterable filter, or it may perform the initial stage of filtration slope at a slow speed, thereby reducing filtration performance.

Therefore, Adtech made recommendations to Indonesia Aluminium that Ceramic Filter Indonesia Aluminium needs to be baked before use. Usually it is baked on air for 15-20 minutes.

In smelting, refining and metal forming, especially in molten metal casting, it is desirable to separate inclusions from molten metal.

The inclusion of such impurities results in the presence of the raw materials used to form the melt, from slag, foam and oxides, in the form of slag, waste and oxides on the surface of the melt, and small fragments from refractory materials. Used to form chambers or containers where smelted to form molten metal.

If these inclusions are not removed from the molten state of the metal, it may lead to the weakening of the final solidified metal body point (the final product of the casting operation) and/or the reduction of porosity.

According to Adtech’s understanding, Indonesian mining company expects Inalum to be listed by the end of 2022

On September 27, 2021, Orias Petrus Moedak, CEO of the state-owned mining holding company Mining Indonesia (MIND ID), stated that the company is seeking an initial public offering (IPO) for its bauxite mining business around the end of next year.

CEO Orias Petrus Moeldak also said that as the controlling shareholder, the State-owned Enterprise Department is currently separating MIND ID and its bauxite business Inalum into two entities in preparation for the IPO. If the separation process can end this year or early next year, they hope the IPO can be launched by the end of 2022.

Ogi Prastomiyono, Director of Strategic Services at MIND ID, said: “Inalum is conducting due diligence for the IPO and has not yet determined the details of the planned stock offering.” Inalum will continue to focus on bauxite mining and processing, including the construction of an alumina refinery. After Inalum goes public, the company will begin to discuss whether it needs MIND ID for IPO.