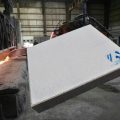

Ceramic Filter Inalum is mainly used in the filtration process of aluminum and aluminum alloy production. It can effectively remove various inclusions in the aluminum water with a fineness of micrometers, so that the aluminum water becomes a smooth laminar flow.

It has excellent aluminum water erosion resistance, strictly controlled hole size and through-hole rate, which can provide a stable filtering effect for aluminum rod factories and aluminum ingot factories, thereby improving casting quality.

Large-size Ceramic Filter Inalum is widely used in aluminum melting and casting workshops such as aluminum alloy casting rods, slabs, aluminum foil, aluminum can materials and aluminum profiles, etc.

Alumina foam ceramic filter, suitable for the temperature of 1000 ° ℃, suitable for the filtration and purification of aluminum and alloy solutions. In order to meet the increasingly high quality requirements of aluminum castings, it is more and more important to use oxidized ceramic foam filters.

The alumina foam ceramic filter product effectively removes the solid inclusions in the molten metal, so the aluminum alloy can be successfully forged, aluminum foil manufacturing, extrusion processing and other processes to obtain aluminum products.

The product has a selection range of 20ppPPI to 60ppPPI, so there will always be a product standard that suits your requirements.

Indonesia will stop exporting bauxite, how much impact will it have on China’s alumina demand?

Why does Indonesia stop exporting bulk commodities and raw materials?

As a resource-rich country, Indonesia has also made a lot of money due to the surge in commodity prices in recent years.

However, Indonesian President Joko recently stated that Indonesia is preparing to suspend the export of all bulk raw materials. Although Indonesia has been restricting the export of raw materials in recent years, the term “all” has still aroused heated discussions.

On November 25, the Netherlands International Group issued a report stating that Indonesia’s move was to attract foreign investment, allowing Indonesia’s raw materials to be processed locally and then exported, which would help export semi-finished or finished products with higher value. Invite investment, develop the smelting industry, and increase employment.

Coincidentally, in August this year, Malaysia also issued a scrap copper import restriction policy, which aims to promote Malaysia’s development as a global copper scrap transit trade center and promote the development of the smelting industry.

Recently, Indonesia’s import share has shrunk. How big is the impact?

Judging from the October import data, the main sources of China’s bauxite were Guinea, Australia, and Indonesia. Among them, Indonesia’s imports fell 16.14% year-on-year.

Take Indonesia as an example. It is nearer to China and the freight is cheap. Indonesia is an island country with many good ports, which is conducive to transportation. In addition, most of the bauxite mines in Indonesia are located offshore, so it is more convenient to build alumina plants.

Since the establishment of the China-ASEAN Free Trade Area in 2010, the cooperation between Indonesia and China has gradually increased, and the government has led a number of alumina construction projects. Large enterprises such as China Hongqiao Group and Shandongnanshan Aluminum have put into production projects in the local area.

The overseas layout of large aluminum companies is in line with the current domestic environmental protection trend and Indonesia’s economic development needs. It is expected that more large aluminum companies will increase investment in overseas alumina projects in the future.

In general, Indonesia announced that it will ban the export of bauxite, which will have little impact on the overall supply of bauxite in China. In the short term, Guinean imports and inventories are the support; in the long term, the output of foreign alumina projects continues to increase and is supplied to the country, so the Chinese market will not cause too much impact.