Ceramic filter foam can effectively remove various inclusions in the aluminum water with a fineness of micrometers, so that the aluminum water becomes a smooth laminar flow, which is conducive to punching.

These impurities usually cause bubbles and inclusions in the slab, which seriously affect the purity of the molten metal, thereby further affecting the processing performance, mechanical properties, corrosion resistance and product appearance quality.

Today, there are many ways to remove these harmful substances and purify the aluminum melt.

According to different methods, these methods can be divided into two categories: furnace processing and continuous processing outside the furnace (ie online processing).

According to the role, it can be divided into two types: mainly degassing or deslagging. The ceramic casting filter manufacturer (www.adtechamm.com) introduced a method of continuous filtration of aluminum melt using foam ceramic filter plates. External continuous treatment, the main purification operation is to remove slag.

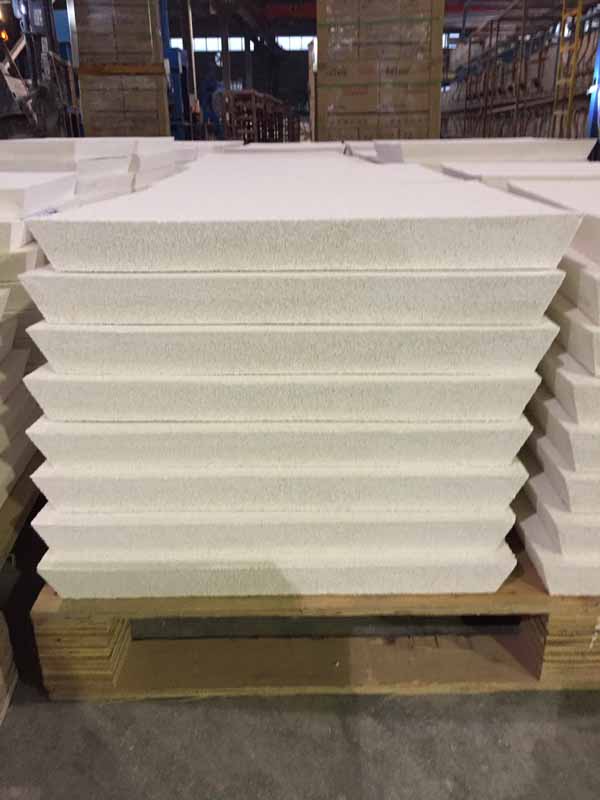

Ceramic filter foam has a certain strength mesh structure, which can withstand the pressure difference of the metal liquid surface and the influence of the metal flow, but it is brittle and brittle. Due to the precise structure of this material, uniform quality and large surface area, the filtering effect is excellent.

30ppi 40ppi casting filter usually uses polyurethane foam as a carrier, immersed in a ceramic slurry made of fine powder (such as refractory aggregate sintering aid, binder and water), and then squeezes out the excess slurry. The ceramic material around the foam fiber is dried, fired and sintered at high temperature, and finally the foam ceramic product is left.

Because the casting temperature of the casting alloy is different, the foam ceramic filter of refractory material should be selected for casting.

To solve this problem, a simple filter made of metal wire mesh, steel plate with holes, etc. is inserted into the gating system to remove impurities from the beginning.

To the inner filter with two-dimensional structure such as silicate needle fibers and boron nitride fibers.

Nowadays, ceramic foam filters use pore sizes to mechanically intercept large particles of mixed oxide, and filter cakes to filter small particles of mixed oxide.

It also has the functions of adsorption and rectification. The production line using foam ceramic filters significantly increases the output of castings.

Ceramic foam filter

660x660x50 (26″)

584x584x50 (23″)

508x508x50 (20″)

432x432x50 (17″)

381x381x50 (15″)

305x305x50 (12″)

228x228x50 (9″)

178x178x50 (7″)

Ceramic foam clamp hole size (PPI): 10/20/30/40/50/60

Molten aluminum in a melting furnace before further processing – casting into ingots or castings – almost always requires filtration. Filtration methods depend on the casting technology used or the method of processing aluminum melt. generally considered, that it is possible and beneficial only when working with large enough volumes of metal. However, filters can be used for large industries., and in small foundries, including for filtering metal during casting of each individual cast. Filter dimensions depend on its expected performance., the duration of casting and the location of the filter in the filter unit. Filter brand selection (ppi values) determined by the features of aluminum alloy, casting temperature, degree of contamination of the melt and the required level of purity of the metal at the exit.