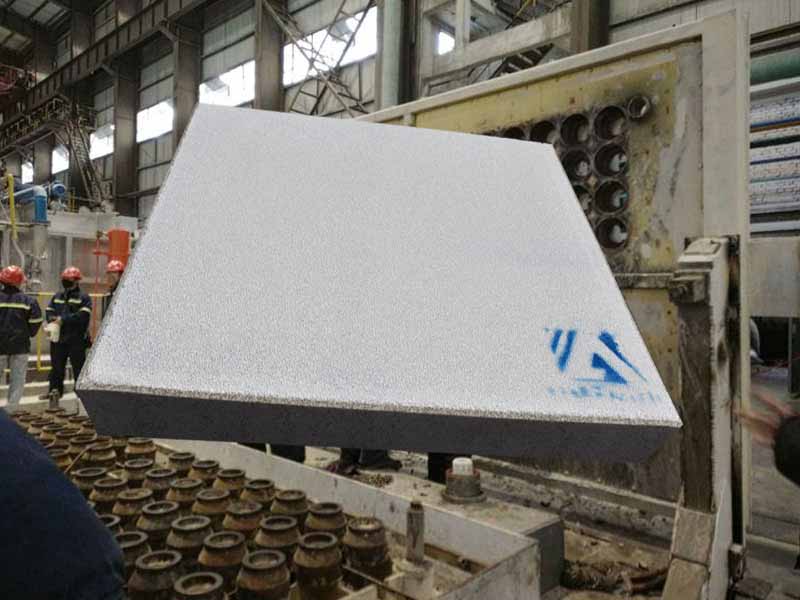

Ceramic Filter Egypt aluminium can effectively remove impurities in molten aluminum, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner.

Due to its excellent resistance to wear and corrosion of molten aluminum, it continues to provide high-quality clean aluminum products during the aluminum casting process, reducing waste and reducing inclusion defects, all of which help increase profits.

Products can be made through specific procedures and have unique structural pores, just like the shape of foam (called 3D contact channels) and infinite pores (can only be found under a large microscope).

Compared with similar products, Ceramic Filter Egypt aluminium has the following advantages

1. Stable chemical composition

2. Outstanding strength

3. High temperature resistance

4. Soothes metal disorders

Foam ceramic plate filtration: Foam ceramic is a new type of ceramic filter material developed in recent years. Generally, a filter plate with a thickness of 50mm and a length of 200~600mm is made, and the porosity is 8-0.9.

When the foam ceramic plate is filtering the molten aluminum, the molten aluminum flows through the tortuous holes of the ceramic, and the inclusion particles contained in it are trapped in the ceramic plate due to the combined effect of the axial pressure, friction, and surface adsorption force of the molten aluminum flow. The inner surface of the hole and the crevice cave, so that the inclusion particles and the aluminum liquid are separated.

The slag remaining on the ceramic plate after a period of time also participates in the adsorption and interception of the slag. Its ability to adsorb and trap molten aluminum is much greater than that of the ceramic plate, making it possible for the ceramic filter plate to filter out slag that is much smaller than its own perforation. Generally speaking, the thicker the ceramic plate, the smaller the eye, and the aluminum liquid passes through the ceramic plate. The slower the flow rate, the better the filtering effect.

The total amount and cleanliness of the molten aluminum not only affect the filtering effect, but also affect the service life of the ceramic plate. Usually, the filter device with foam ceramic plate is similar to the glass cloth filter, and it is directly placed on the shunt plate. Before casting, the ceramic plate should be preheated to about 600 degrees. Because the ceramic plate is hard and brittle and has poor thermal conductivity, the initial addition should be slow. When preheated to above 200 degrees, the heating speed can be increased, otherwise the ceramic plate is easy to break.

Recently, according to foreign media reports, the Egyptian government intends to start the modernization and upgrading project of Egypt Aluminum, the country’s only aluminum producer.

Egyptian Aluminum was put into operation in 1975, with a designed aluminum production capacity of 320,000 tons.

At the end of 2019, it was proposed to modernize and upgrade it and expand its aluminum production capacity to 570,000 tons.

However, due to the impact of the coronavirus, the project has not been launched.

Recently, the government intends to restart this project.

Hisham Tawfiq, Minister of State of Egypt, stated that Bechtel of the United States is preparing a feasibility study for the project, and the feasibility study is expected to be completed in the middle of this year.

The project is planned to be carried out in two phases, one is to replace the old production line, and the other is to add a new production line.

According to Tawfiq, six foreign companies have expressed interest in participating in tenders for the supply of major equipment.