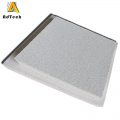

Ceramic Filter Aluminum Indonesia is mainly used to filter aluminum and alloys in foundries and foundries.

Asian Foundry Filter has excellent resistance to molten aluminum erosion and corrosion, can effectively remove inclusions, reduce trapped gas and provide laminar flow, so that the filtered metal is cleaner.

Cleaner metals will produce higher quality castings, less scrap and fewer inclusion defects, all of which help increase profits.

Alumina ceramic filtration

Ceramic Filter Aluminum Indonesia is produced on the basis of a solid network structure carrier and composite organic foam pores.

The production process is as follows. The carrier is put into the thixotropic alumina slurry, and the square correction automatic extrusion process is adopted to make the slurry uniformly deposit in the carrier foam skeleton. After drying and solidification, the carrier is baked into a finished product. High temperature of 1180℃.

Alumina ceramic filtration

Installed in the filter bowl to filter the impurities in the molten aluminum alloy to meet the production requirements of aluminum alloy precision casting with high added value and high technical performance, such as computer hard disks, PS substrates for printing, canned materials, turbojet engine fan blades, etc.

News from Jakarta, January 22. Oggy Achmad Kosasih, managing president of the Indonesian state-owned refinery-Inalum (PT Indonesia Asahan Aluminium), said in an interview on Wednesday that the company plans to increase its aluminum smelting capacity from the current 250,000 tons/year to 1 million tons/year.

He said that the company plans to build a new smelter with an annual production capacity of 500,000 tons in North Kalimantan of the country. The smelter project is currently in the feasibility study stage and is expected to cost up to 2 billion US dollars. It will take “several years”. Complete the construction.

He also said that the company also plans to double the capacity of its Kuala Tanjung smelter in North Sumatra to 500,000 tons per year.

He said that the company’s access to electricity will add another 200 megawatts.

The company plans to produce about 235,000 tons of aluminum this year and further increase to 300,000 tons by 2020.

terjemahan bahasa indonesia

Berita dari Jakarta, 22 Januari. Oggy Achmad Kosasih, Managing President Inalum, PT Indonesia Asahan Aluminium, mengatakan dalam sebuah wawancara pada hari Rabu bahwa perusahaan berencana untuk meningkatkan kapasitas peletahunton.

Dia mengatakan perseroan berencana membangun smelter baru dengan kapasitas produksi tahunan sebesar 500.000 ton di wilayah Kalimantan Utara, yang saat ini dalam tahap studi kelayakan dan diperkirakan menelan biaya hingga dokan” saiber tahap miliar.

Dia juga mengatakan perseroan juga berencana melipatgandakan kapasitas smelter Kuala Tanjung di Sumatera Utara menjadi 500.000 ton per tahun.

Dia mengatakan, akses listrik perseroan akan menambah 200 megawatt lagi.

Perusahaan berencana untuk memproduksi sekitar 235.000 ton aluminium tahun ini dan selanjutnya meningkat menjadi 300.000 ton pada tahun 2020.