Ceramic Casting Filter

There is very little functional difference between primary (extracted or pure) and secondary (recycled) Recycling Aluminum Die Castingsaluminum when it refers to die casting. Secondary aluminum alloys are derived from mixing and melting pure aluminum with other materials such as magnesium, iron, and copper. The use of pure aluminum in casting is quite rare due to the cost of extraction. The ease of use in die casting combined with lighter weight and durability make aluminum alloys a top choice for designers from nearly any industry.

Continuous Cast Ceramic Casting Filter

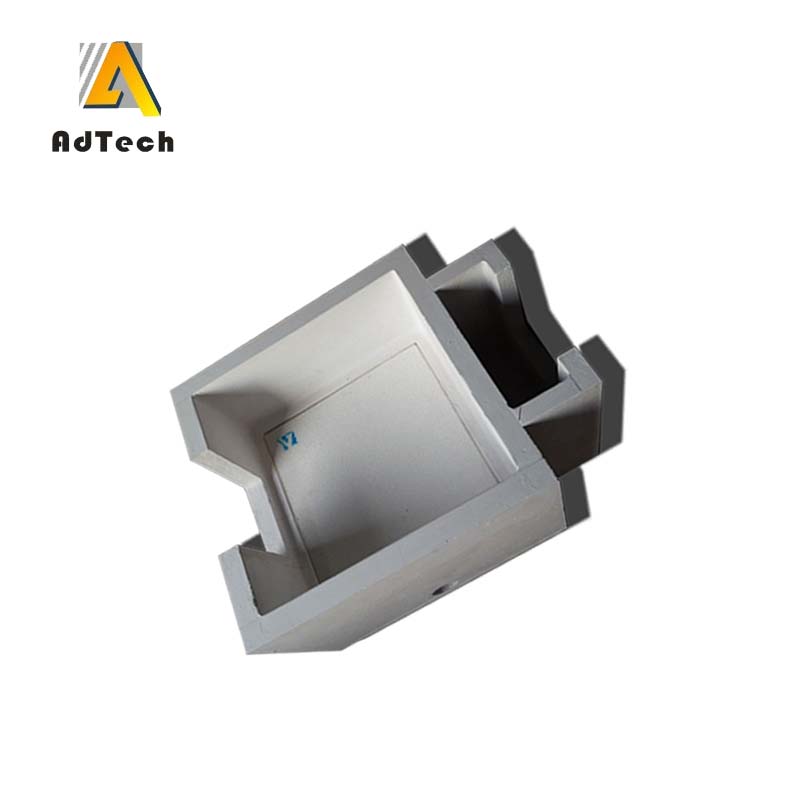

This application includes companies engaged in rolling, drawing, and extruding aluminum alloy basic shapes such as plate, sheet, strip, bar, and tubing. In the process of continuous casting of aluminum, coolants and industrial water are used to cool the caster wheel or caster belt, lubricate mill components and transfer aluminum particulate and contaminants to filtration systems using gravity filters or vacuum filters. Particulate and contaminants are removed by the filter and system pumps transfer clean coolant back to the work. Continuous casting produces aluminum rod, sheet and rolled products as well. Complete system packages including tanks, pumps, heat exchanger and controls.

Aluminum Rolling Ceramic Casting Filter

This application includes companies that are engaged in flat rolling aluminum and aluminum base alloy basic shapes, such as sheet, plate, and foil. Also included is production of similar products by continuous casting. For rolled aluminum applications, coolant filtration is necessary. The hot rolling process uses a water-soluble coolant that requires continuous flat bed air-vacuum filtration to eliminate staining of the sheet. The cold rolling process uses a kerosene-based rolling oil which requires recovery by vacuum distillation to remove heavy hydrocarbon oils and greases from the oil. Complete system packages including tanks, pumps..

Aluminum Wire Drawing Ceramic Casting Filter

This application includes companies engaged in rolling, drawing, and other operations resulting in the production of aluminum wire, rolled and continuous cast rod and bar. The continuous cast rod and wire drawing processes typically use a straight drawing oil or water-soluble coolant, depending on the application. To prevent build up of contaminants in the coolant, it must be continuously filtered. For viscous oils, a centrifuge operating on a bypass basis provides the required clarification. Complete system packages including tanks, pumps, heat exchanger and controls can be proposed.