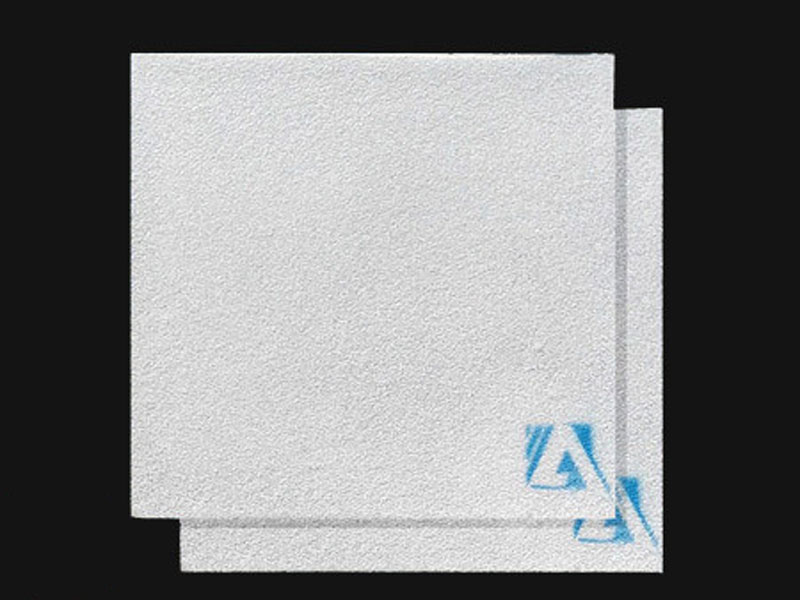

Casting Filter Nordic Aluminium has the advantages of large filtration area, good thermal shock stability, high chemical stability, good metal erosion resistance and good filtration efficiency.

Therefore, as a new type of high-efficiency filter in the metal melt filtration and purification technology, people’s attention has been paid.

At present, its application range has been extended to precision casting, cast steel industry and foundry industry. Foam ceramic filters can improve the mechanical properties of castings, reduce the rate of casting rejects, increase the rate of finished castings, and extend the service life of metal cutting tools.

Due to the closed cells in the ceramic foam, its thermal efficiency is reduced and the heat transfer in the convection process is reduced, so that the ceramic foam has the characteristics of low thermal conductivity and good thermal shock resistance. It is an ideal heat-resistant material.

The melt-loss alumina foam ceramic filter has the characteristics of corrosion resistance, high temperature resistance, high mechanical strength, no harmful substances dissolution, and no secondary pollution.

The micropores are not deformed under the action of liquid pressure, are easy to clean and regenerate, and have a long service life. Widely used in metallurgical environmental protection enterprises.

Casting Filter Nordic Aluminium should have the following characteristics

It has sufficient mechanical strength at normal temperature and high temperature, so that it can withstand the impact of transportation vibration, extrusion and high-temperature molten metal during use.

It has suitable refractoriness and low thermal expansion coefficient, so that it will not soften and deform under the long-term action of high-temperature molten metal.

It has excellent high temperature chemical stability, so that it will not be corroded by high temperature molten metal and avoid metal pollution.