Casting Filter for Casting is mainly used for filtering aluminum and aluminum alloys in foundries and foundries, and can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner.

Cleaner metals can produce higher-quality castings, fewer scraps and fewer inclusion defects, all of which help increase profits.

Inclusions can form pores and generate thermal cracks during the solidification process, causing surface defects to damage the appearance and often reduce mechanical properties.

In many cases, filtering reduces these causes of waste to almost zero. It is common to increase the output to nearly 100% and reduce the scrap rate to 0% or close to 0%.

Casting Filter for Casting has all common sizes

7″, 9″, 12″, 15″, 17″, 20″ and 23″.

We provide all porosities from PPI 10 to PPI 60 (PPI = number of holes per inch). You can also customize the size of the Casting Filter.

Gasket of Casting Filter for Casting

The edge of CFF-AL is equipped with gaskets. The gasket ensures the correct and tight position of the filter in the Filtering Housing. There are different types of gaskets, for example. Ceramic fiber gaskets, etc. You can also choose CFF without gaskets.

Casting Filter function for aluminum castings.

Purify molten metal liquid

Simplify the gating system

Improve the metallurgical structure of castings

Reduce slag inclusion in castings

Improve casting qualification rate

Reduce internal reoxidation defects in castings

Reduce surface defects after casting

Casting Filter is basically divided into 6 pore sizes: 10PPI, 15PPI, 20PPI, 25PPI, 30PPI, and 40PPI. The larger the number, the smaller the aperture. But in actual practice, the four types of 10PPI 20PPI 30PP 40PPI can meet the needs of customers.

Aperture selection

1. The casting: 10~25ppi

2. Semi-continuous casting: 30~60ppi

3. High-quality aluminum or sheet: 50~60ppi

4. Continuous casting and rolling: 50~60p

How to choose Casting Filter?

1. Aluminum alloy bar selection: 10-30ppi

2. Long-term casting options: 30-50ppi

3. High-quality aluminum profile or plate selection: 40 or 50ppi

4. Double zero wave continuous casting and rolling options:> 50ppi

5. Other specifications can be customized according to your requirements

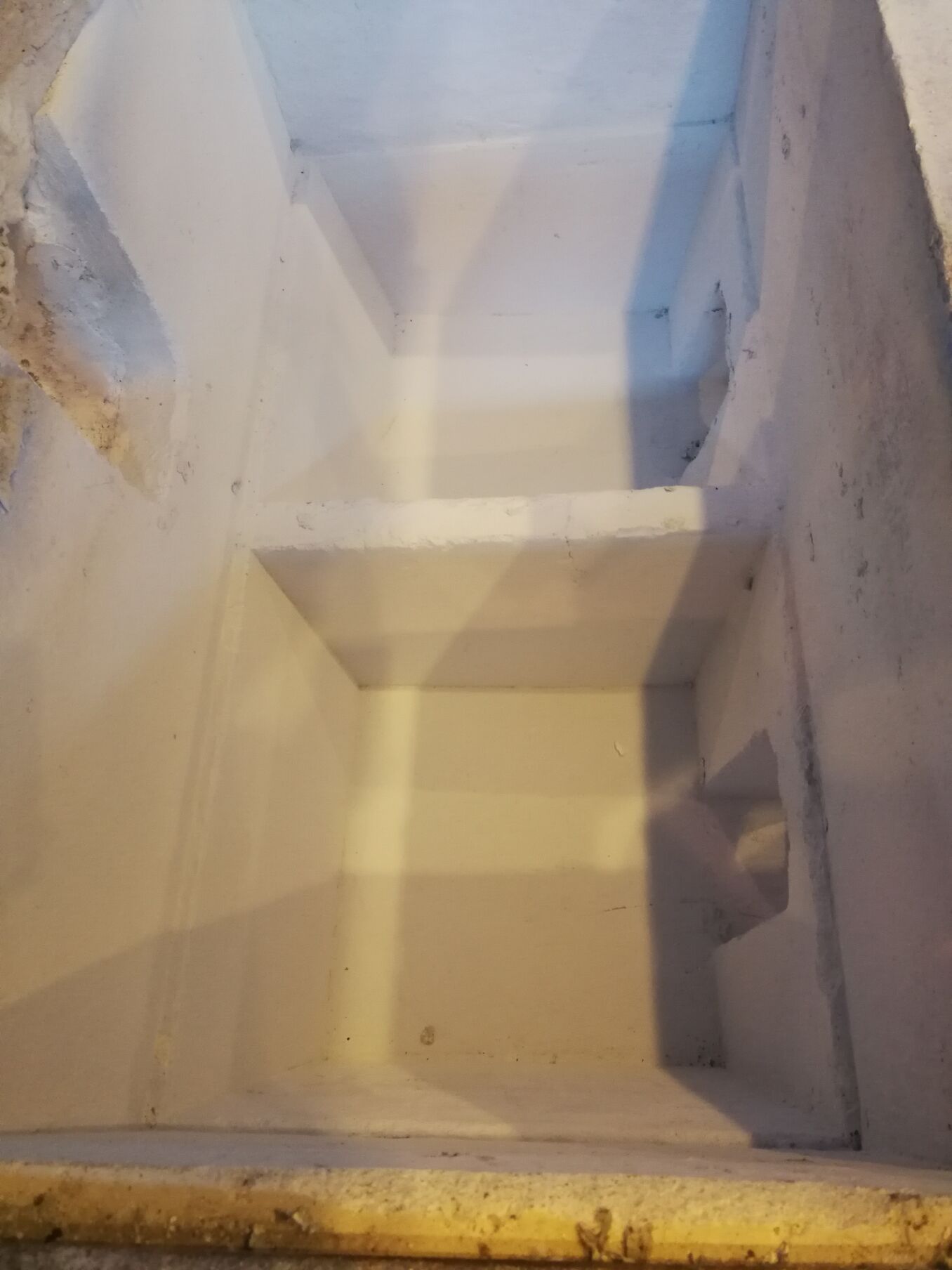

The best results when filtering liquid aluminum are achieved then, when the filter is placed directly in the gate system, which is used for casting a cast product (picture 9). These filters are disposable..