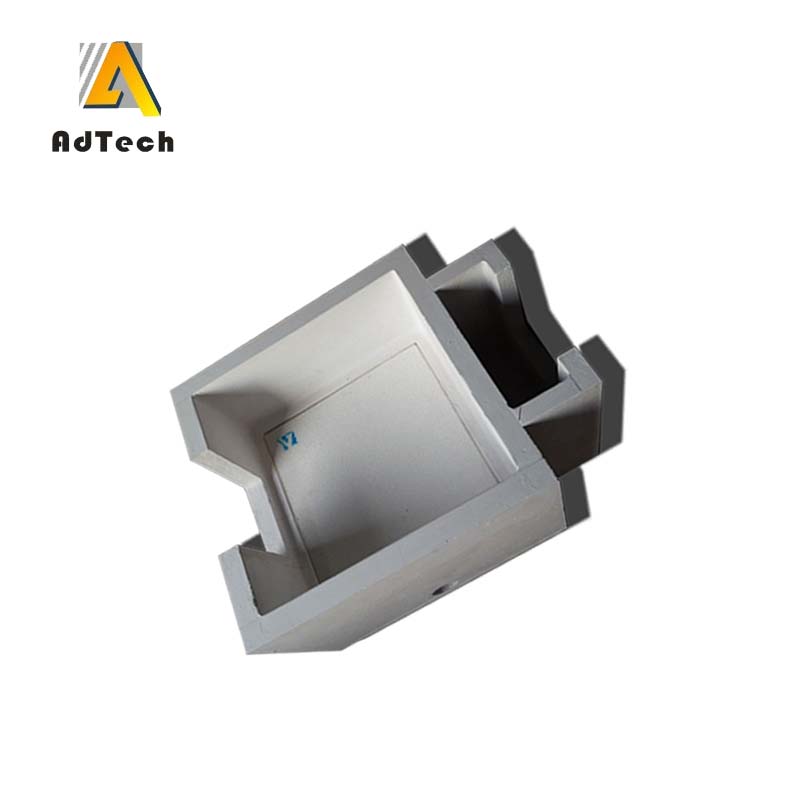

Casting Filter is an alumina foam ceramic filter, which uses a three-dimensional network structure and organic bubbles connected to the pores as a carrier to invade the thixotropic alumina material slurry.

Adopt full-automatic pressing technology, center correction, make the slurry evenly spread on the foam skeleton of the carrier, and bake and solidify at high temperature of 1180℃.

Installed in the filter box for aluminum alloy liquid impurity filtering, non-stick aluminum ceramic filter plate, to meet the production of high value-added, high-tech performance aviation, transportation and other aluminum alloy precision casting.

Such as: computer hard disk, printed PS board base, can making materials, jet turbine engine fan blades and other products.

Casting Filter product use

AdTech ceramic filter plate uses a three-dimensional network structure and organic bubbles connected to the pores as a carrier to invade the thixotropic alumina slurry, and uses a four square correction center distance automatic extrusion process to make the slurry evenly coated. The carrier foam skeleton is baked and cured at a high temperature of 1180°C after drying. Installed in the filter box for aluminum alloy liquid impurity filtering, to meet the production of high value-added, high technical performance aviation, transportation and other aluminum alloy precision casting. Such as: computer hard disk, printed PS board base, can making materials, jet turbine engine fan blades and other products.

MALAYSIAN ALUMINIUM & ALLOYS SDN BHD (MAA) introduces the advantages of ceramic filter plates

1. Filtration using the adsorption principle can effectively remove large inclusions in the aluminum liquid and effectively adsorb small inclusions of small size.

2. No slag, effectively reduce aluminum liquid pollution.

3. Good thermal shock resistance, improved corrosion resistance to molten metal.

4. Automated assembly line production, three calibration procedures, accurate size, more in line with filter box.

5. Improve surface quality, improve product performance, and improve microstructure.

How does EL Aluminium Billet(M)SDN BHD use ceramic filter plates?

1. Check and clean the debris on the surface of the filter box to keep the filter box clean and free of damage.

2. Gently put the Casting Filter into the filter box and press the seal around the filter plate with your hand to prevent the aluminum liquid from flowing or floating.

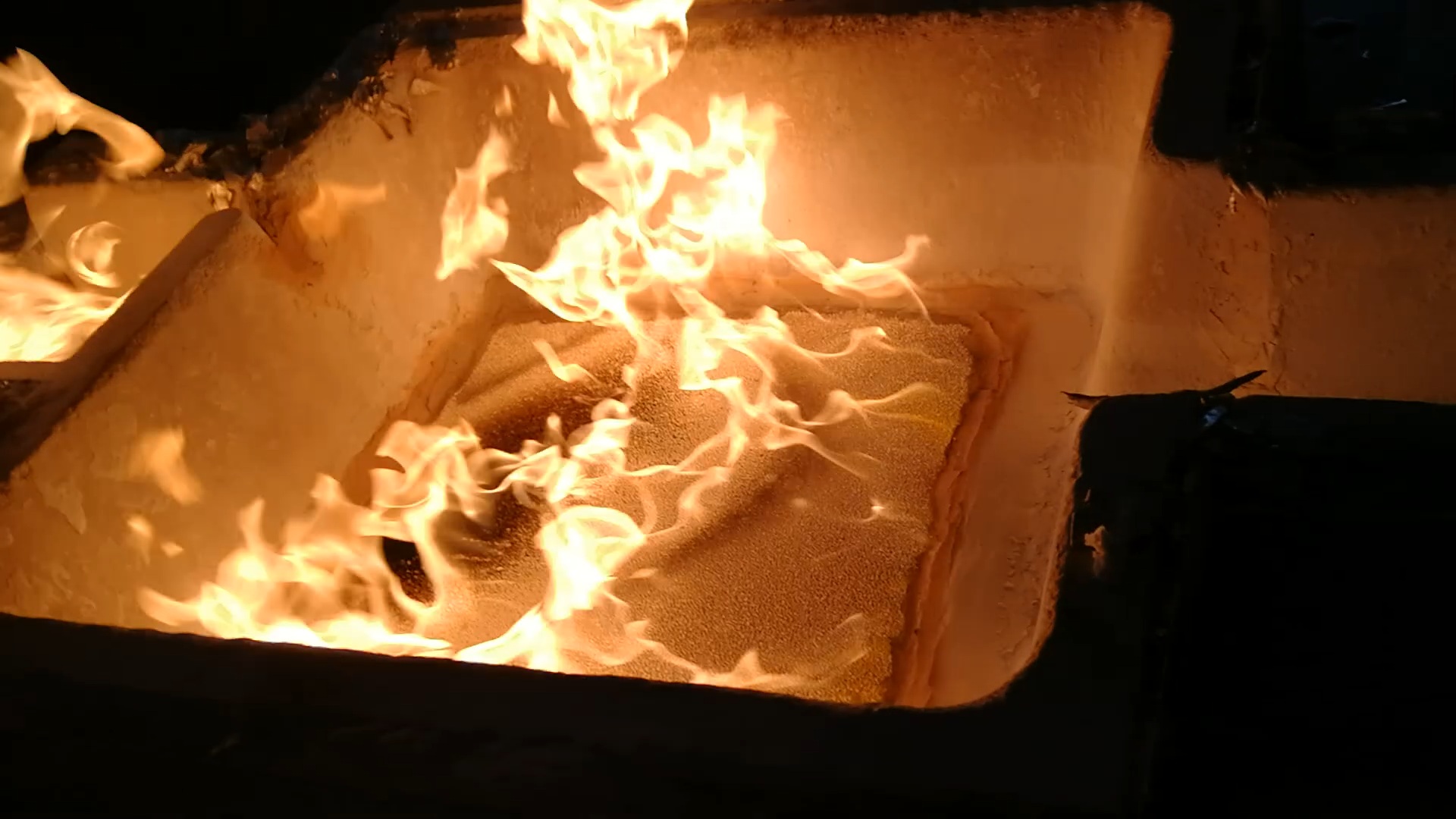

3. Preheat the filter box and filter plate evenly to bring it close to the temperature of molten aluminum. The preheating temperature of the filter plate is not lower than 260℃.

Preheating to remove the adsorbed water helps the initial opening of the filter pores, preventing thermal expansion and contraction from causing local pore blockage in the filter plate.

Preheating can use electric heating or gas heating, normal heating for 15-30 minutes.

4. Observe the changes of the aluminum liquid head during the casting process to maintain the normally required control flow of the aluminum liquid. The normal starting head is 100-150mm. When the molten aluminum begins to pass, the indenter will fall below 75-100mm, then the indenter will slowly increase.

5. During normal filtration, avoid knocking and shaking the filter plate. At the same time, the tank should be filled with molten aluminum to avoid interference of too large or too small molten aluminum.

6. After filtering, the filter plate should be removed in time to clean the filter box.