Cast Foam Filter plays a very important role in the aluminum liquid purification system.

The ceramic filter plate can effectively remove the large inclusions in the aluminum liquid, effectively remove the micron-level fine inclusions, improve the surface quality and product performance, improve the microstructure function, and improve the yield.

As long as it is used for aviation, transportation and other aluminum alloy precision casting.

The ceramic filter plate adopts a three-dimensional network structure and a porous organic carrier, invades a special thixotropic ZrO2 melt, and adopts a square correction center distance automatic extrusion process, so that the slurry is evenly coated on the carrier foam, the skeleton is in 1680 Drying and curing at ℃ high temperature, with expanded cotton edge sealing.

EL Aluminium Billet (M) SDN BHD said that the commonly used ceramic filter plate specifications are: 7in, 9in, 12in, 15in, 17in, 20in, 23in, 26in or customized according to user’s special requirements.

The range is from 1.5×1.5×0.5 inches to 26x26x2 inches and 28x24x2 inches.

EL Aluminium recommends using a 6×6” or larger filter with a thickness of 1.25” or 2” instead of the usual 7/8”.

The advantage of the 1.25 inch thick filter is that the bending strength is significantly higher than the 7/8 inch thick filter. Therefore, the filter can also be used for larger castings or longer casting times.

Customize solutions as needed (for example, cone filters).

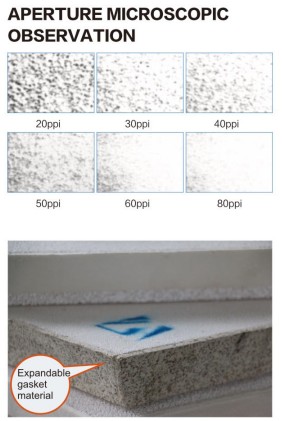

Cast Foam Filter has a porosity of PPI 10, 20 and 30, and can provide finer porosity on request, up to PPI 60.

The choice of porosity depends on the cleanliness that should be achieved. Generally, ppi10 or ppi20 are used in daily production because these porosities provide a good relationship between filtration capacity and filtration efficiency.

For castings with high mechanical strength and/or high surface appearance requirements (such as automotive applications), PPI 30 filters are recommended.

Choose the right aluminum casting foam ceramic filter size

The following two basic rules apply to foam ceramic filters in aluminum casting applications: filtration capacity: approximately 14.2-28.4 lb/in2 casting speed: approximately 0.7-1.42 lbs/inch 2*s

Up to 4×4 inch filters can be placed vertically or horizontally in the mold/runner. Larger filters can only be placed horizontally. It is not recommended to place the filter at the bottom of the descending channel because the risk of filter damage is greatly increased. When using foam ceramic filters, it is recommended to use a “no-pressure” casting system to prevent the oxidation of molten aluminum during casting.