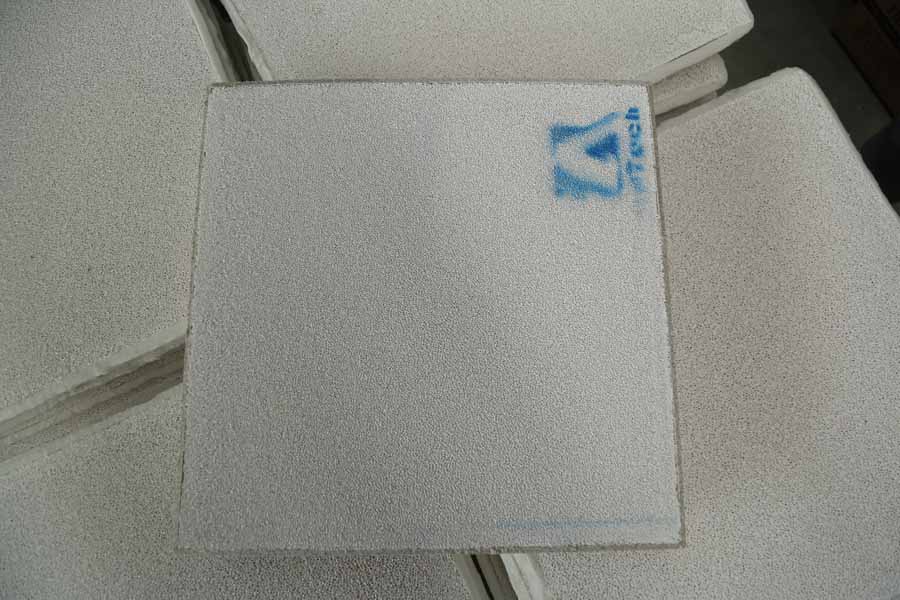

Buy Foundry Filters to remove big piece inclusions in molten aluminum, and effectively adsorb tiny inclusions.

Superior thermal shock resistance, improve erosion resistance ability of molten metal.

No broken bits drop out, effectively reduce the pollution of molten aluminum.

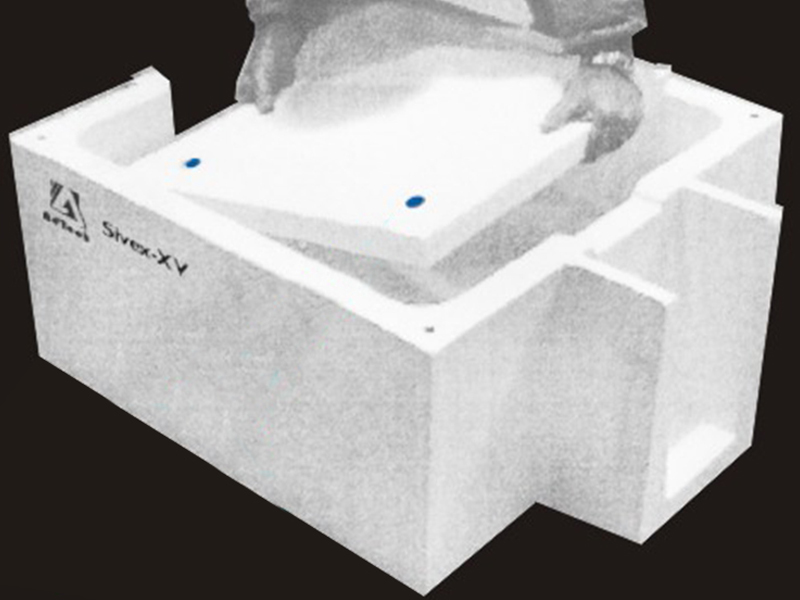

Automatic flow production,3 calibration procedures,precision size,fit the filter bowl tightly.

Improve the surface appearance and performance, purify molten aluminum.

Ceramic Foam Filter employs dedicated Molten Aluminium Foam Filter to remove inclusions which are generated between the refining system and the mold table.

The ability of the foam ceramic filter to capture these inclusions is critical to maintaining a clean ingot during the solidification of metal.

Accordingly, the quality and the productivity in downstream operations such as forging, extruding, and rolling are guaranteed.

Ceramic Foam Filter mainly for filtration of aluminum and alloys in foundries and cast houses.

With the excellent resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas and provide laminar flow and then the filtered metal is significantly cleaner.

Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.