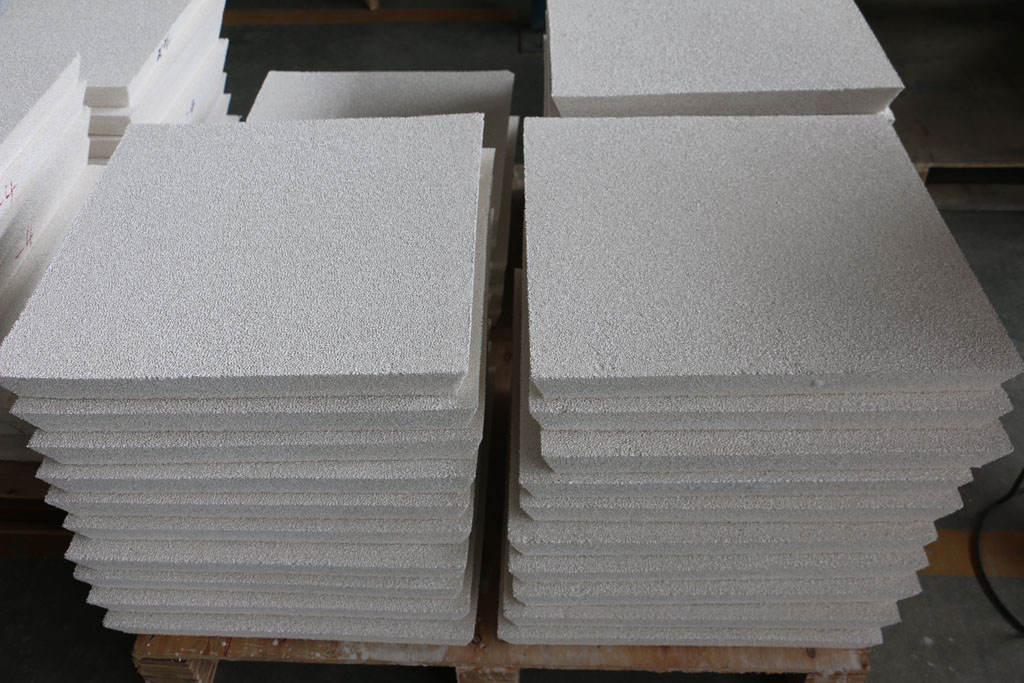

Ceramic foam filter for filtration of nonferrous aluminium alloys casting process, filters for filtering cast iron with flaky and spheroidal graphite and filters intended for steel filtration are therefore used in practice. Depending on the cast material, Al2O3, SiC, ZrO2 or graphite based filters are applied.

How to make Ceramic Foam Filter For aluminium casting.

The polymeric-sponge method, which will be described in more detail here, produces open-cell structures by impregnating a polymeric sponge with a ceramic slurry, which is then burned out to leave a porous ceramic.

The direct foaming method can produce both open-cell and closed-cell structures, with the foam structure more common.

In this method, a chemical mixture containing the desired ceramic component and organic materials is treated to evolve a gas.

Bubbles are then produced in the material, causing it to foam.

The resulting porous ceramic material is then dried and fired. For the honeycomb or cellular structure, a plastic-forming method called extrusion is used, where a mixture of ceramic powder plus additives is forced through a shaped die. The cellular structure can also be produced using a pressing method.