Buy Ceramic Filter Malaysia with Technology of aluminium casting to purify the molten aluminium in the CFF Box Machine.

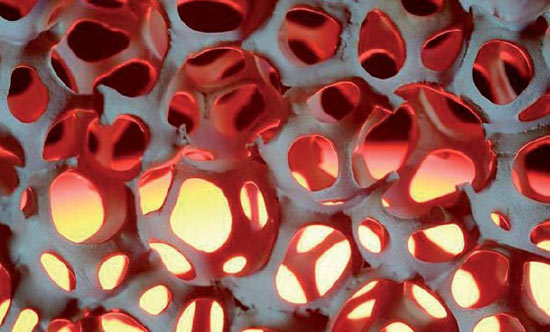

Ceramic Filter Malaysia uses three-dimensional mesh structure and connected to the pores of the organic foam as a carrier.

Ceramic Filter Malaysia invades the thixotropic alumina slurry, the use of four square correction center distance automatic extrusion technology, The slurry was evenly applied to the carrier’s foam body skeleton and baked and cured at a high temperature of 1180°C.

Ceramic Filter Malaysia is installed in the filter box for aluminum alloy liquid impurity filtration, to meet the production of high value-added, high-tech performance aviation, transportation and other aluminum alloy precision casting.

Such as: computer hard drives, printing PS base, can making materials, jet turbine engine fan blades and other products.

The basic structure of ceramic filter plate: Ceramic filter plate consists of plate base, positioning seat, outlet, and surface film.

Buy Ceramic Filter Malaysia for aluminium casting, whichi is one of the core components of the ceramic filter.

Ceramic Filter is covered with criss-crossing capillary pores (about 1 to 10 microns in diameter).

This is the channel of the filtrate. This component is called the plate base layer.

The components of the ceramic filter plate are silicon carbide, corundum and other materials.

The main components of the outlet and positioning base of the ceramic filter plate are composed of stainless steel or polymer material.